Preparation method of high-activity anti-sulfur-poisoning palladium carbon catalyst

A palladium-carbon catalyst and sulfur poisoning technology, which is applied in the preparation of organic compounds, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems that the reaction performance cannot be fully exerted, and achieve good practical value, strong sulfur poisoning ability, high The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of highly active anti-sulfur poisoning palladium carbon catalyst, comprises the following steps:

[0031] Step 1, adding activated carbon to a hydrochloric acid solution with a mass concentration of 2% for cooking for 1 hour, the temperature of the cooking treatment is 80°C, filtering, adding the filtered activated carbon to a nitric acid solution with a mass concentration of 4% for cooking for 1 hour, and cooking The temperature of the solution is 80°C, filtered, washed with pure water until the pH is 6, and acid-treated activated carbon is obtained; the quality of the hydrochloric acid solution is 6 times that of the added activated carbon; the quality of the nitric acid solution is 6 times that of the activated carbon added to the hydrochloric acid solution 6 times the mass;

[0032] Step 2, the acid-treated activated carbon described in step 1 is added in the modifier solution, stirred for 10min to obtain slurry; 1%, the modifier is sod...

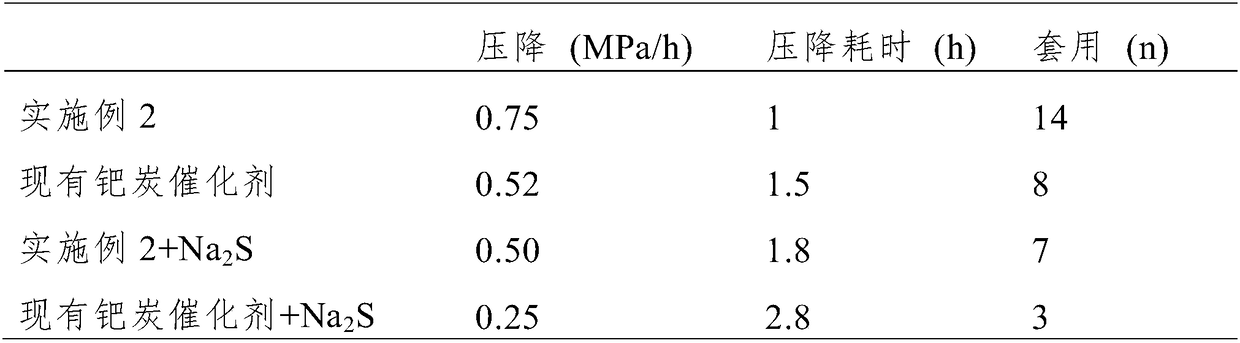

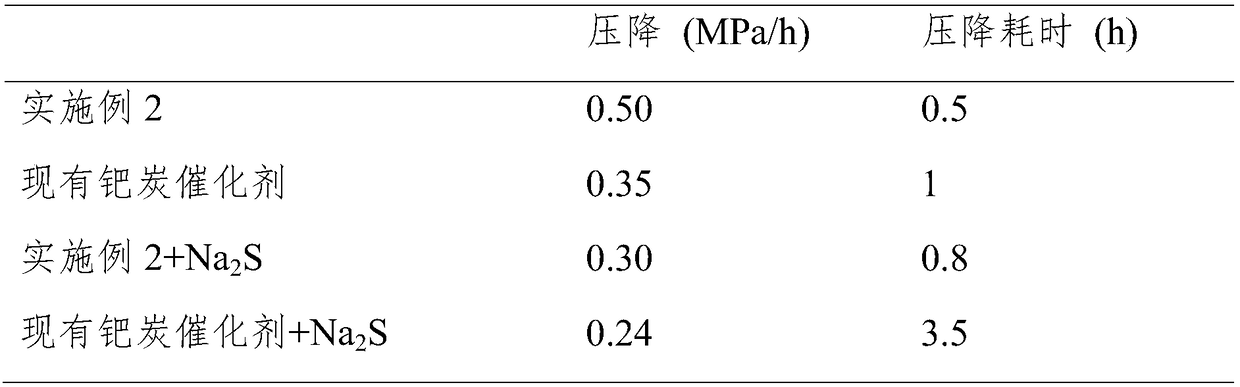

Embodiment 2

[0038] A kind of preparation method of highly active anti-sulfur poisoning palladium carbon catalyst, comprises the following steps:

[0039]Step 1, adding the activated carbon to the hydrochloric acid solution with a mass concentration of 2% and cooking for 0.5h, the temperature of the cooking treatment is 90°C, filtering, adding the filtered activated carbon to the nitric acid solution with a mass concentration of 4% and cooking for 0.5h, The temperature of the cooking treatment is 90°C, filtered, washed with pure water until the pH is 7, and acid-treated activated carbon is obtained; the quality of the hydrochloric acid solution is 8 times that of the added activated carbon; the quality of the nitric acid solution is 8 times that of the added hydrochloric acid solution. 8 times the mass of activated carbon;

[0040] Step 2, the acid-treated gac described in step 1 is added in the modifier solution, stirred for 20min to obtain a slurry; 5%, the modifier is dodecylbenzenesul...

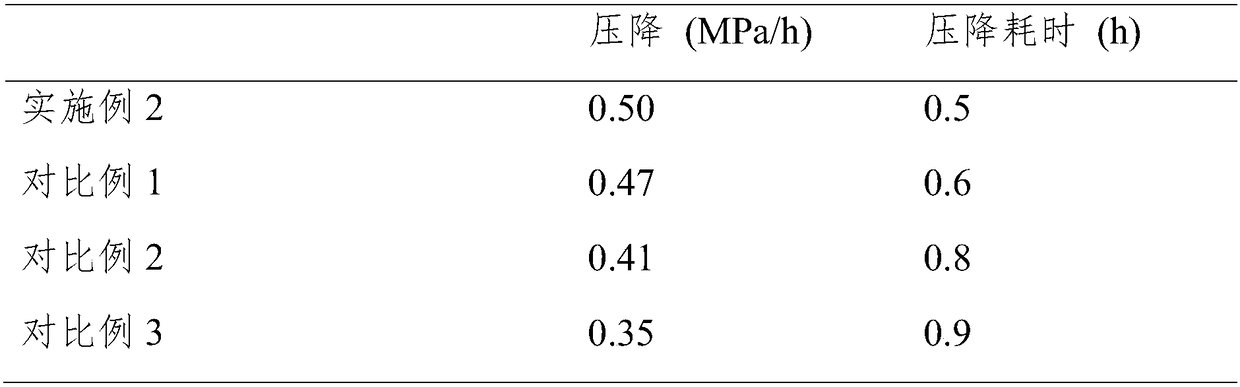

Embodiment 3

[0045] A kind of preparation method of highly active anti-sulfur poisoning palladium carbon catalyst, comprises the following steps:

[0046] Step 1, adding the activated carbon to the hydrochloric acid solution with a mass concentration of 2% and cooking for 0.25h, the temperature of the cooking treatment is 100°C, filtering, adding the filtered activated carbon to the nitric acid solution with a mass concentration of 4% and cooking for 0.25h, The temperature of the cooking treatment is 100°C, filtered, washed with pure water until the pH is 8, and acid-treated activated carbon is obtained; the quality of the hydrochloric acid solution is 10 times that of the added activated carbon; the quality of the nitric acid solution is 10 times that of the added hydrochloric acid solution. 10 times the mass of activated carbon;

[0047] Step 2, the acid-treated activated carbon described in step 1 is added in the modifier solution, stirred for 30min to obtain a slurry; the modifier solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com