Sintering aid and quartz ceramics and their preparation and application methods

A technology of quartz ceramics and sintering aids, applied in the field of quartz ceramic materials, can solve the problems of easy crystallization, damage to application value, high sintering temperature, and achieve the effects of large application value, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] 3. Preparation method of quartz ceramics

[0067] The preparation method at least comprises the following steps:

[0068] (1) Add the sintering aid to the fused silica powder to obtain a mixed raw material, and add deionized water and ball milling media to the mixed raw material;

[0069] (2) Ball milling;

[0070] (3) Heating the slurry obtained by ball milling, and then sieving;

[0071] (4) Granulate the sieved mixture;

[0072] (5) Dry press the granulated mixture, the dry pressure is 80~120MPa, and hold the pressure twice, the first holding time is 45~60s, and the second holding time is 20~30s ;

[0073] (6) Sintering the pressed mixture at 1150-1300° C. to obtain the quartz ceramics.

[0074] During specific implementation, the raw material fused silica powder can be prepared by the technical staff or purchased on the market.

[0075] During specific implementation, the ball milling medium can be selected or adjusted according to actual needs, for example, a...

Embodiment 1

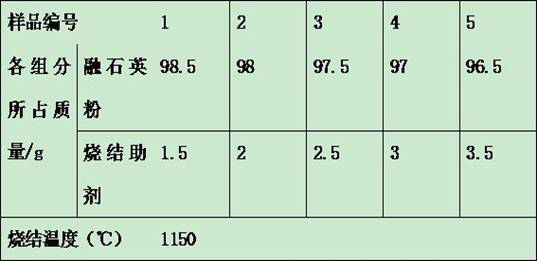

[0096] According to the above preparation method, and specifically adjust the composition ratio of quartz and sintering aids and the sintering temperature, the quartz ceramic samples numbered 1~5 are obtained, as shown in the following table:

[0097]

Embodiment 2

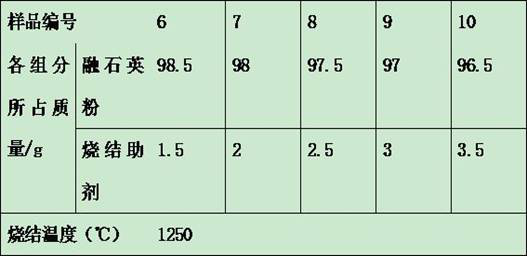

[0099] According to the above preparation method, and specifically adjust the composition ratio of quartz and sintering aids and the sintering temperature, the quartz ceramic samples numbered 6~10 are obtained, as shown in the following table:

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com