Mica compound titanium dioxide used for paint and preparation method

A technology for compounding titanium dioxide and titanium dioxide, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of poor coating effect, restricting development and application, easy agglomeration, etc., and achieves simple preparation process and low cost. Inexpensive, anti-agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

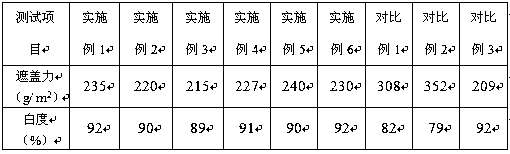

Examples

Embodiment 1

[0030] (1) Mix mica, fatty acid methyl ester sulfonate and isopropanol evenly, and then transfer to a ball mill for ball milling. With the assistance of isopropanol, fatty acid methyl ester sulfonate infiltrates the mica surface and collects the ball milling mixture ; Fatty acid methyl ester sulfonate is sodium fatty acid methyl ester sulfonate; the material-ball ratio of the ball mill is 1:2, the ball diameter is 7mm, the ball mill speed is 56r / min, and the ball mill time is 4h;

[0031] Wherein, 84 parts by weight of mica, 9 parts by weight of fatty acid methyl ester sulfonate, 7 parts by weight of isopropanol;

[0032] (2) Spray-dry the ball-milled mixture obtained in step (1), and collect the dried material; the speed of spray-drying is 21000r / min, the inlet temperature is 210°C, the outlet temperature is 86°C, and the diameter of the spray disc is 130mm;

[0033] (3) Mix the dried product obtained in step (2) with titanium dioxide, add water to make a slurry, and then per...

Embodiment 2

[0037] (1) Mix mica, fatty acid methyl ester sulfonate and isopropanol evenly, and then transfer to a ball mill for ball milling. With the assistance of isopropanol, fatty acid methyl ester sulfonate infiltrates the mica surface and collects the ball milling mixture ; Fatty acid methyl ester sulfonate is sodium fatty acid methyl ester sulfonate; the material-ball ratio of the ball mill is 1:1, the ball diameter is 6mm, the ball mill speed is 50r / min, and the ball mill time is 5h;

[0038] Wherein, 87 parts by weight of mica, 8 parts by weight of fatty acid methyl ester sulfonate, 5 parts by weight of isopropanol;

[0039] (2) Spray-dry the ball-milled mixture obtained in step (1), and collect the dried material; the speed of spray-drying is 16000r / min, the inlet temperature is 180°C, the outlet temperature is 80°C, and the diameter of the spray disc is 50mm;

[0040] (3) Mix the dried product obtained in step (2) with titanium dioxide, add water to make a slurry, and then perf...

Embodiment 3

[0044] (1) Mix mica, fatty acid methyl ester sulfonate and isopropanol evenly, and then transfer to a ball mill for ball milling. With the assistance of isopropanol, fatty acid methyl ester sulfonate infiltrates the mica surface and collects the ball milling mixture ; Fatty acid methyl ester sulfonate is sodium fatty acid methyl ester sulfonate; the material-ball ratio of the ball mill is 1:2, the ball diameter is 8mm, the ball mill speed is 60r / min, and the ball mill time is 3h;

[0045] Wherein, 80 parts by weight of mica, 12 parts by weight of fatty acid methyl ester sulfonate, 8 parts by weight of isopropanol;

[0046] (2) Spray-dry the ball-milled mixture obtained in step (1), and collect the dried material; the speed of spray-drying is 25000r / min, the inlet temperature is 250°C, the outlet temperature is 90°C, and the diameter of the spray disc is 200mm;

[0047] (3) Mix the dried product obtained in step (2) with titanium dioxide, add water to make a slurry, and then pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com