Heat treatment process for high-wear-resistance round-link chain

A technology of circular link chain and heat treatment method, which is applied in the direction of heat treatment furnace, heat treatment equipment, metal material coating process, etc., and can solve problems such as easy cracking of link weld joints, insufficient understanding of temper brittleness, and unstable dimensional pitch. , to achieve the effect of short service life, high production efficiency and high quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

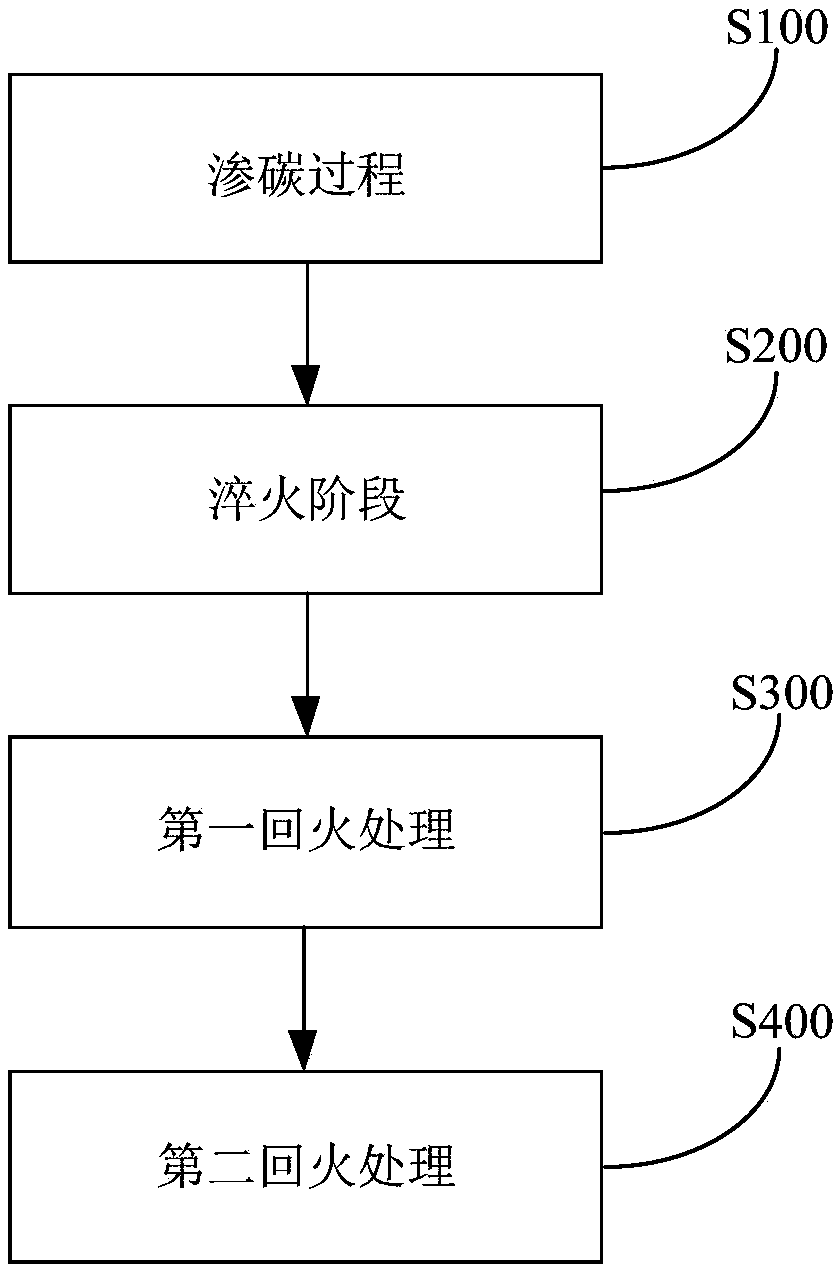

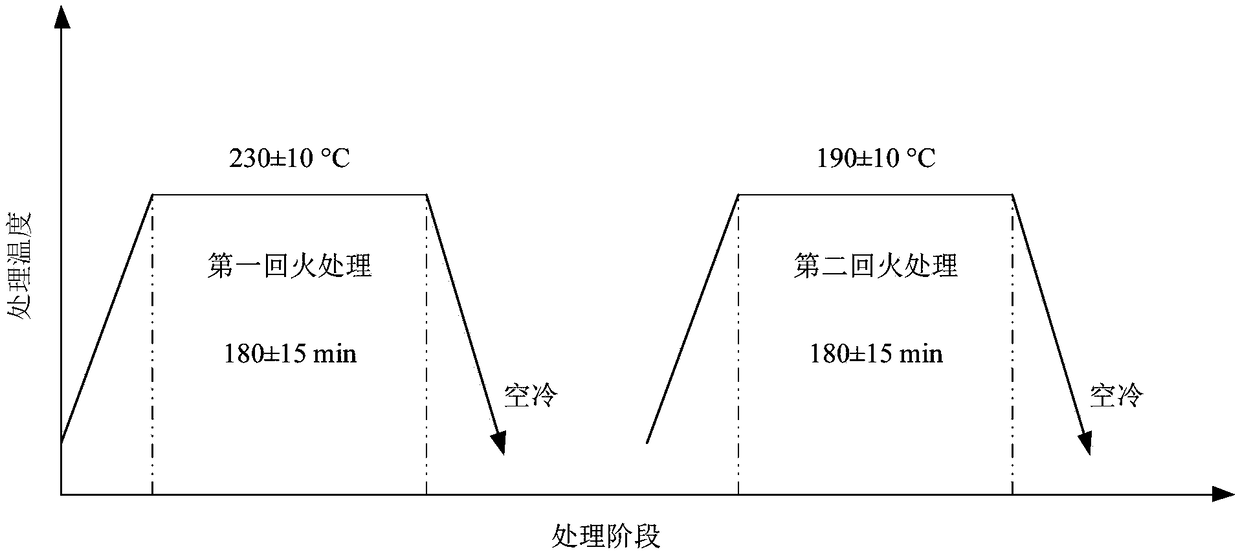

[0056] refer to figure 2 and 3 , heat treatment of the circular link chain.

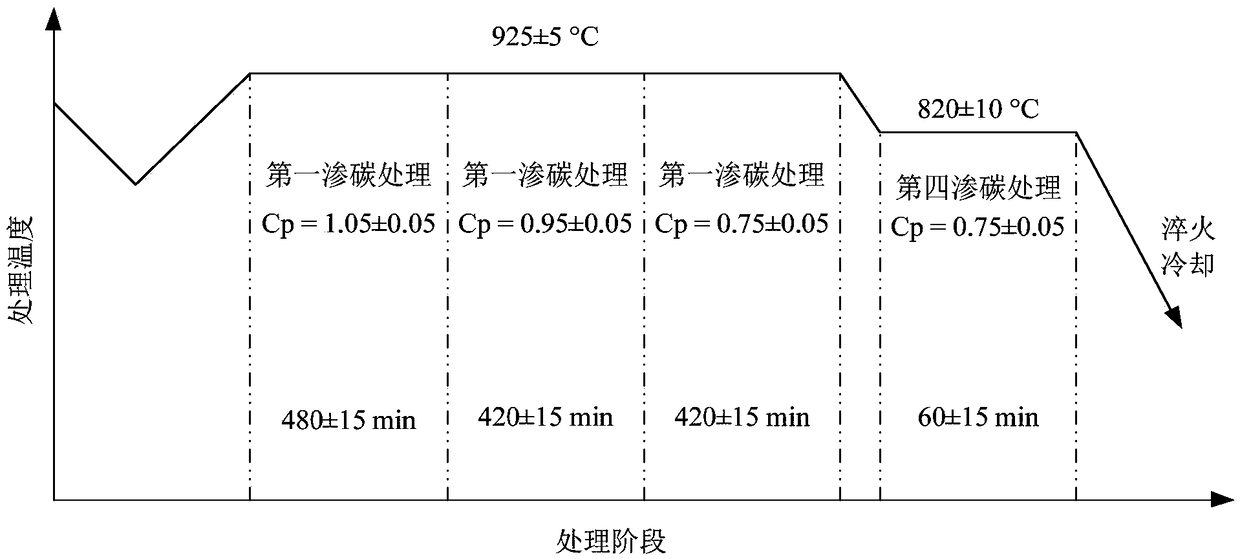

[0057] (1) First, raise the temperature of the empty furnace to 700°C, and at the same time turn on the circulating cooling water to control the furnace temperature, feed propane gas into the furnace to carburize the empty furnace, and continue to heat up until the furnace temperature reaches the carburizing temperature of 920°C, and the carbon potential is 1.0 %, heat preservation for carburizing for 8h;

[0058] (2) After the above carburizing, reduce the carbon potential to 0.9%, and carry out carburizing for 7 hours with heat preservation;

[0059] (3) After the above-mentioned carburizing is completed, the carbon potential drops to 0.7%, and the carburizing is carried out for 7 hours with heat preservation;

[0060] (4) After the carburizing is completed, the furnace temperature is lowered to 810°C, the carbon potential is 0.7%, and the heat preservation is carried out for 1 hour for deep ca...

Embodiment 2

[0065] refer to figure 2 and 3 , heat treatment of the circular link chain.

[0066] (1) First, raise the temperature of the empty furnace to 800°C, turn on the circulating cooling water at the same time, pass propane gas into the furnace to carburize the empty furnace, continue to heat up until the furnace temperature reaches the carburizing temperature of 930°C, and the carbon potential is 1.1%. Carburizing 8h;

[0067] (2) After the above carburizing, reduce the carbon potential to 1.0%, and keep warm for 7 hours;

[0068] (3) After the above-mentioned carburizing is completed, the carbon potential drops to 0.8%, and the carburizing is carried out for 7 hours with heat preservation;

[0069] (4) After the carburizing is completed, the furnace temperature is lowered to 810°C, the carbon potential is 0.8%, and the deep carburizing is carried out by holding for 1 hour;

[0070] (5) After carburizing, use 169 rapid quenching oil for quenching and cooling. The medium temper...

Embodiment 3

[0074] refer to figure 2 and 3 , heat treatment of the circular link chain.

[0075] (1) First, raise the temperature of the empty furnace to 750°C, turn on the circulating cooling water at the same time, pass propane gas into the furnace for carburizing the empty furnace, continue to heat up until the furnace temperature reaches the carburizing temperature of 925°C, and the carbon potential is 1.1%. Carburizing 8h;

[0076] (2) After the above carburizing, reduce the carbon potential to 0.9%, and carry out carburizing for 7 hours with heat preservation;

[0077] (3) After the above-mentioned carburizing is completed, the carbon potential drops to 0.7%, and the carburizing is carried out for 7 hours with heat preservation;

[0078] (4) After the carburizing is completed, the furnace temperature is lowered to 825°C, the carbon potential is 0.8%, and the deep carburizing is carried out by holding for 1 hour;

[0079] (5) After carburizing, use 169 rapid quenching oil for qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com