Novel activated carbon filter for air purifier

An air purifier and activated carbon filter technology, applied in chemical instruments and methods, gas treatment, dispersed particle filtration, etc., can solve the problem of not improving the adsorption rate of activated carbon, and achieve increased functional surface area, excellent porosity, and strong removal. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

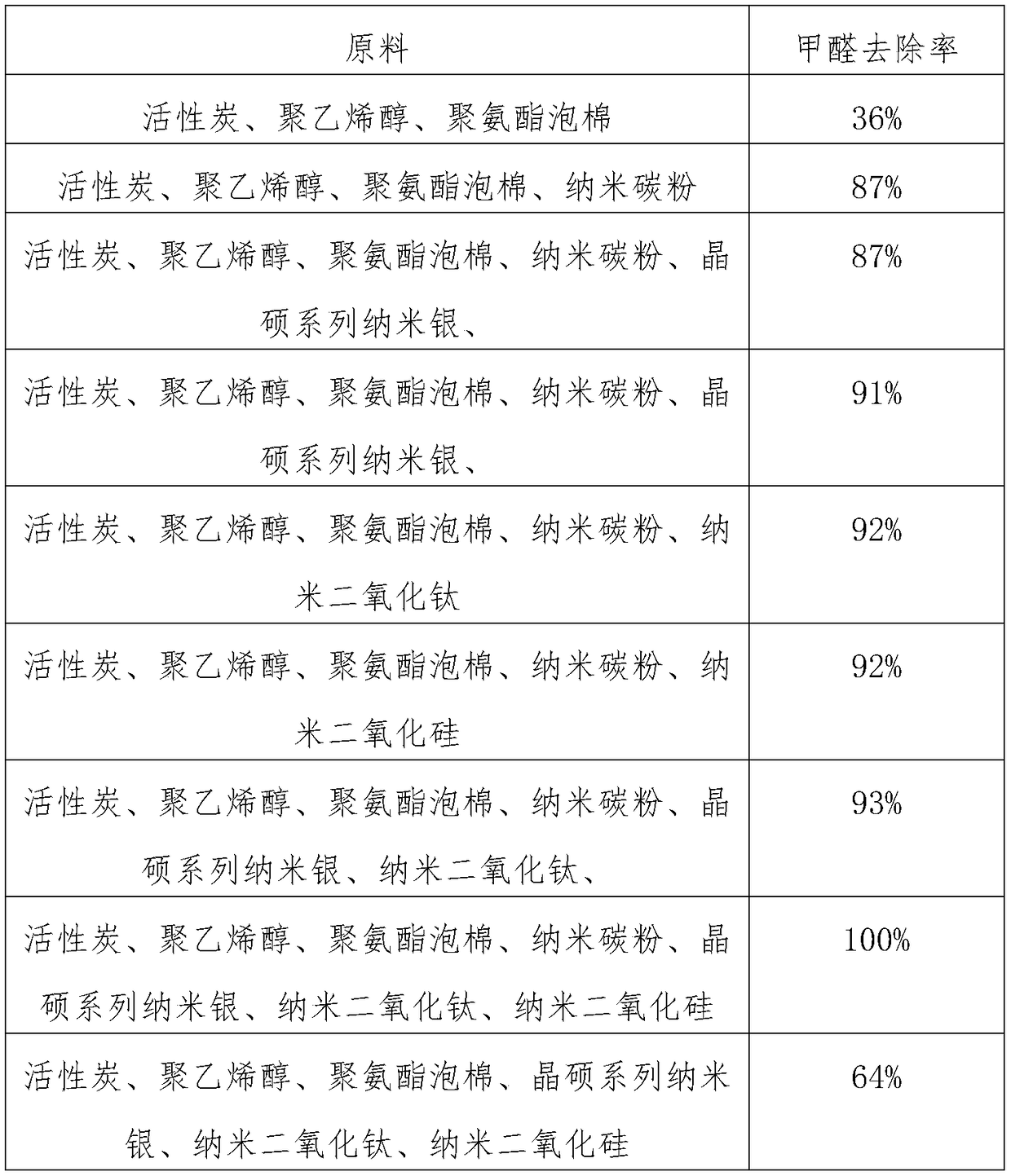

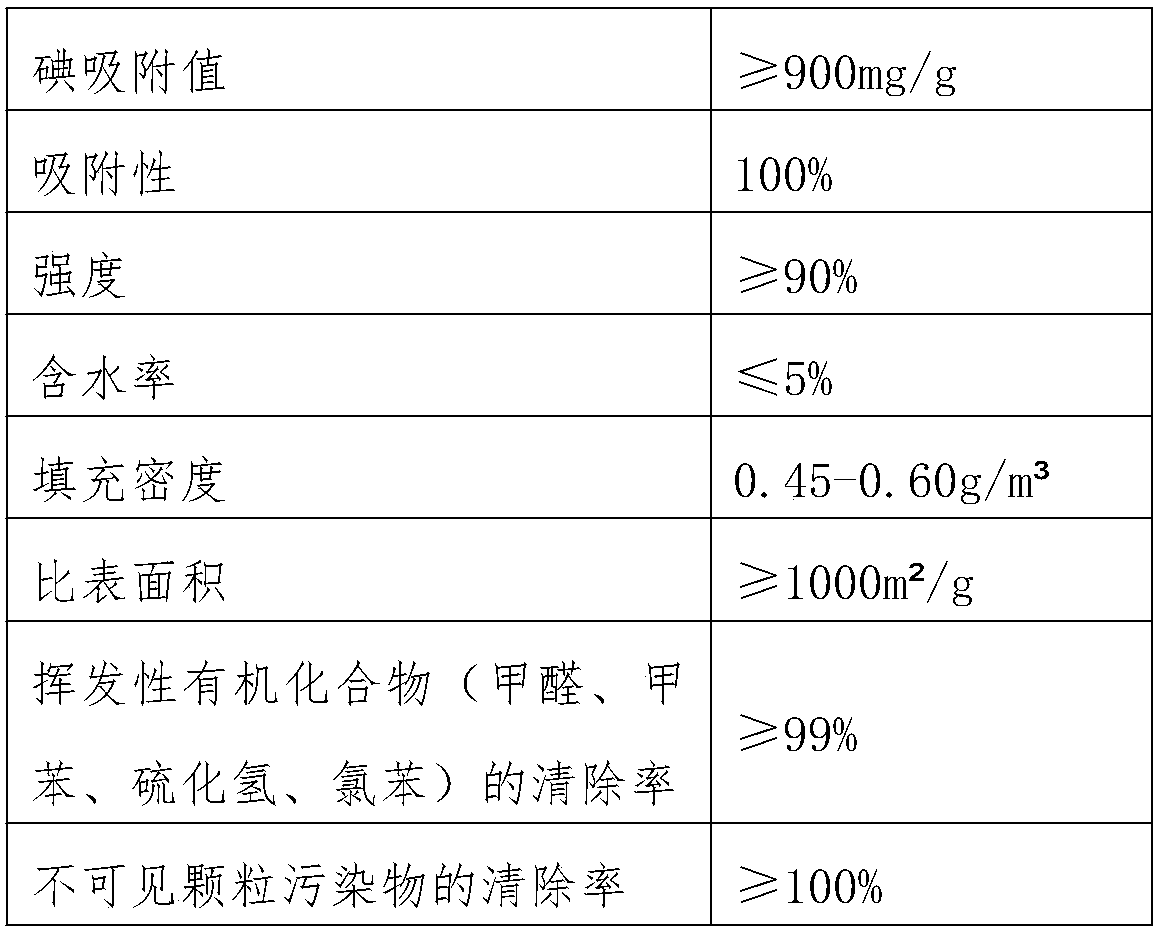

Examples

Embodiment 1

[0025] A new type of activated carbon filter screen for air purifiers is made of the following raw materials by weight percentage: 35% activated carbon, 30% polymer hot-melt material, 2% nano-carbon material, 2% Jingshuo series nano-silver, 2% Oxidant, 2% getter, appropriate amount of polyurethane foam.

[0026] Preferably, the activated carbon is coal-based columnar activated carbon with a particle size of ≤100 mesh.

[0027] Preferably, the nano-carbon material is nano-carbon powder with a particle size of ≤15nm.

[0028] Preferably, the polymer hot-melt material is polyvinyl alcohol.

[0029] Preferably, the oxidant is nano-titanium dioxide with a particle size ≤ 50nm.

[0030] Preferably, the getter is nano silicon dioxide with particle size ≤ 50nm.

[0031] Preferably, the preparation method of the activated carbon filter screen for the novel air purifier comprises the following steps:

[0032] (1) Soak the polyurethane foam in water at 22°C for 5 hours, take it out a...

Embodiment 2

[0040] A new type of activated carbon filter screen for air purifiers is made of the following raw materials by weight percentage: 40% activated carbon, 35% polymer hot-melt material, 3% nano-carbon material, 6% Jingshuo series nano-silver, 4% Oxidant, 4% getter, appropriate amount of polyurethane foam.

[0041] Preferably, the activated carbon is coal-based columnar activated carbon with a particle size of ≤100 mesh.

[0042] Preferably, the nano-carbon material is nano-carbon powder with a particle size ≤ 15 nm or nano-carbon sol with a particle size ≤ 10 nm.

[0043] Preferably, the polymer hot-melt material is polyvinyl alcohol.

[0044] Preferably, the oxidant is nano-titanium dioxide with a particle size ≤ 50nm.

[0045] Preferably, the getter is nano silicon dioxide with particle size ≤ 50nm.

[0046] Preferably, the preparation method of the activated carbon filter screen for the novel air purifier comprises the following steps:

[0047] (1) Soak the polyurethane foa...

Embodiment 3

[0055] A new type of activated carbon filter screen for air purifiers is made of the following raw materials by weight percentage: 50% activated carbon, 40% polymer hot-melt material, 5% nano-carbon material, 8% Jingshuo series nano-silver, 5% Oxidant, 5% getter, appropriate amount of polyurethane foam.

[0056] Preferably, the activated carbon is coal-based columnar activated carbon with a particle size of ≤100 mesh.

[0057] Preferably, the nano-carbon material is nano-carbon powder with a particle size ≤ 15 nm or nano-carbon sol with a particle size ≤ 10 nm.

[0058] Preferably, the polymer hot-melt material is polyvinyl alcohol.

[0059] Preferably, the oxidant is nano-titanium dioxide with a particle size ≤ 50nm.

[0060] Preferably, the getter is nano silicon dioxide with particle size ≤ 50nm.

[0061] Preferably, the preparation method of the activated carbon filter screen for the novel air purifier comprises the following steps:

[0062] (1) Soak the polyurethane f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com