Efficient water purification activated carbon and preparation method thereof

A technology for activated carbon and water purification, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of decreased adsorption capacity, difficulty in purifying water quality, etc., and achieves low cost, good water purification performance, and significant antibacterial properties. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

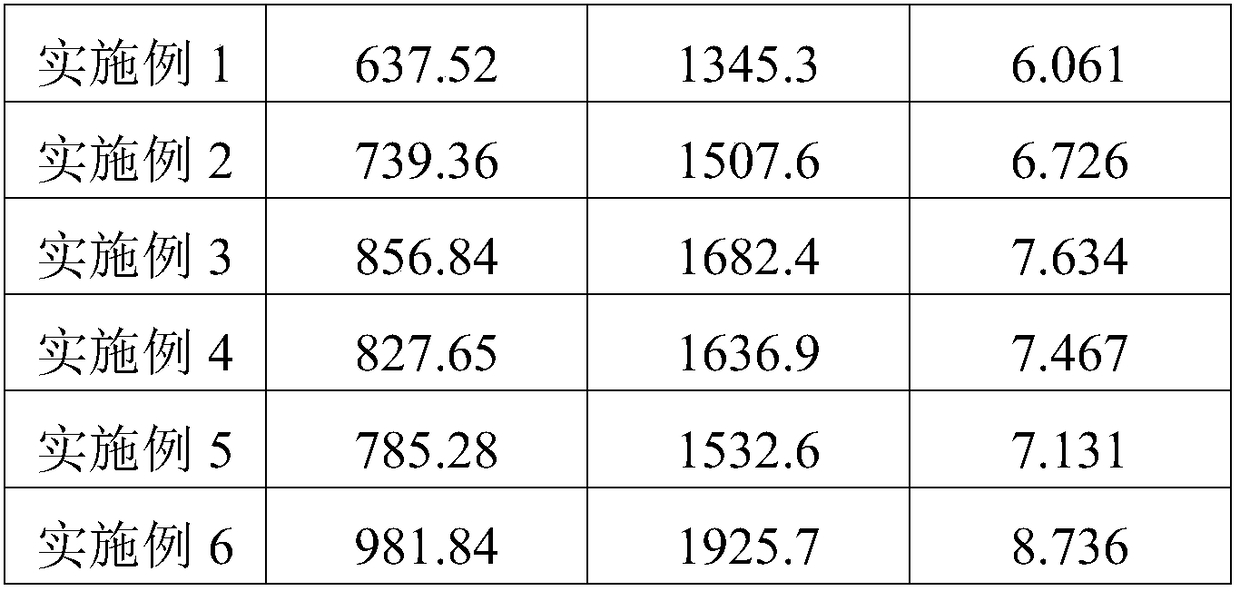

Embodiment 1

[0043] A kind of preparation method of efficient water purification activated carbon comprises the following steps, and described part is weight part:

[0044] (1) Wash pomelo peel, dry at 105° C. for 6 hours, pulverize, and pass through a 40-mesh sieve to obtain pomelo peel coarse powder;

[0045] (2) Mix pomelo peel coarse powder and activator at a solid-to-liquid ratio of 1g:4mL, impregnate at normal pressure for 150 minutes, and filter with a 200-mesh filter cloth to obtain a solid impregnated pomelo peel coarse powder;

[0046] (3) Put the impregnated pomelo peel coarse powder into a tube furnace, raise the temperature to 450° C. at 10° C. / min under nitrogen protection, and keep the temperature at 450° C. for 80 minutes to obtain a carbonized material;

[0047] (4) Take out the carbonized material, mix it with the acid solution according to the solid-to-liquid ratio of 1g: 4mL, soak it under normal pressure for 30 minutes, filter it with a 200-mesh filter cloth, wash the ...

Embodiment 2

[0051] A kind of preparation method of efficient water purification activated carbon comprises the following steps, and described part is weight part:

[0052] (1) Wash pomelo peel, dry at 105° C. for 6 hours, pulverize, and pass through a 40-mesh sieve to obtain pomelo peel coarse powder;

[0053] (2) Mix pomelo peel coarse powder and activator at a solid-to-liquid ratio of 1g: 4mL, impregnate at normal pressure for 120 minutes, then immerse in 80MPa for 30 minutes, filter with 200 mesh filter cloth, and the obtained solid is impregnated pomelo peel coarse powder ;

[0054] (3) Put the impregnated pomelo peel coarse powder into a tube furnace, raise the temperature to 450° C. at 10° C. / min under nitrogen protection, and keep the temperature at 450° C. for 80 minutes to obtain a carbonized material;

[0055] (4) Take out the carbonized material, mix it with the acid solution according to the solid-to-liquid ratio of 1g: 4mL, soak it under normal pressure for 30 minutes, filte...

Embodiment 3

[0059] A kind of preparation method of efficient water purification activated carbon comprises the following steps, and described part is weight part:

[0060] (1) Wash pomelo peel, dry at 105° C. for 6 hours, pulverize, and pass through a 40-mesh sieve to obtain pomelo peel coarse powder;

[0061] (2) Mix pomelo peel coarse powder and activator at a solid-to-liquid ratio of 1g: 4mL, impregnate at normal pressure for 120 minutes, then immerse in 80MPa for 30 minutes, filter with 200 mesh filter cloth, and the obtained solid is impregnated pomelo peel coarse powder ;

[0062] (3) Put the impregnated pomelo peel coarse powder into a tube furnace, raise the temperature to 450° C. at 10° C. / min under nitrogen protection, and keep the temperature at 450° C. for 80 minutes to obtain a carbonized material;

[0063] (4) Take out the carbonized material, mix it with the acid solution according to the solid-to-liquid ratio of 1g: 4mL, soak it under normal pressure for 30 minutes, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com