Preparation method and application of sludge-based activated carbon

A technology of activated carbon and sludge, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 sludge-based activated carbon

[0035] A preparation method of sludge-based activated carbon, comprising the steps of:

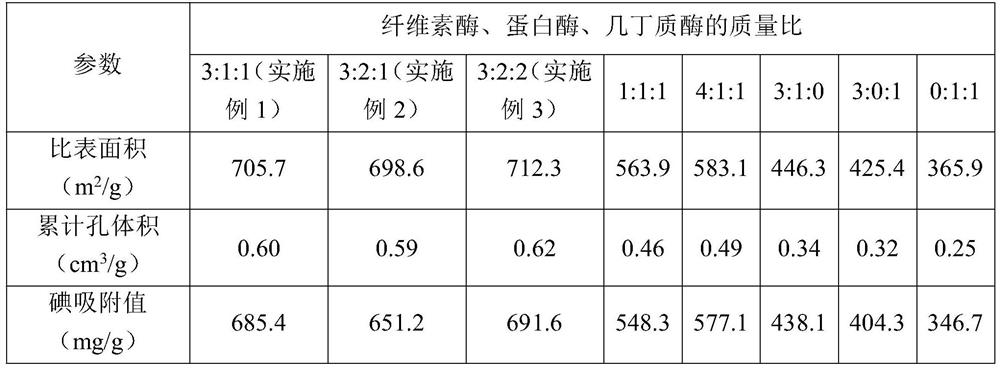

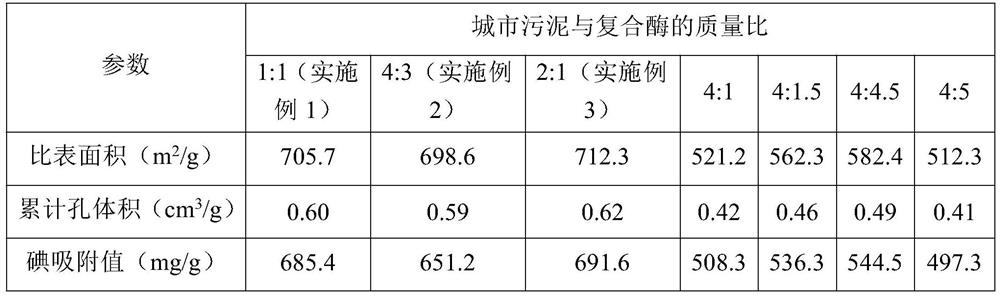

[0036] Add 4g of compound enzyme to 4kg of municipal sludge with a moisture content of 40% (the compound enzyme is formed by mixing cellulase, protease, and chitinase in a mass ratio of 3:1:1), and stir at 40°C 12h, to obtain enzymatic sludge;

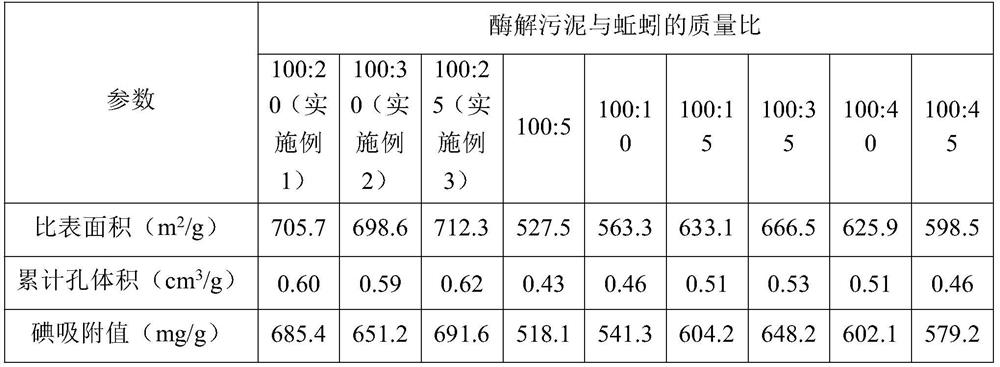

[0037] Add earthworms to the enzymatic sludge (a total of 200g of earthworms with a body weight of 10-15g are added to each kilogram of enzymatic sludge), and under aerobic conditions (pass air into the enzymatic sludge at a flow rate of 1.5L / min) ) at 25°C for 3 days, take out the earthworms, and obtain the treated sludge;

[0038] Dry the treated sludge at 120°C to reduce the moisture content to below 15%, grind, sieve, and retain the sludge particles with a particle size of 100-200 mesh;

[0039] Add an activator to the sludge granules, the activator is ZnCl with a concent...

Embodiment 2

[0043] The preparation of embodiment 2 sludge-based activated carbon

[0044] A preparation method of sludge-based activated carbon, comprising the steps of:

[0045] Add 3g of compound enzyme to 4kg of urban sludge with a moisture content of 50% (the compound enzyme is formed by mixing cellulase, protease, and chitinase in a mass ratio of 3:2:1), and stir at 30°C 24h to obtain enzymatic sludge;

[0046] Add earthworms to the enzymatic sludge (a total of 300g of earthworms with a body weight of 10-15g are added to each kilogram of enzymatic sludge), and under aerobic conditions (pass air into the enzymatic sludge at a flow rate of 1.5L / min) ) were cultured at 20°C for 4 days, and the earthworms were taken out to obtain the treated sludge;

[0047] Dry the treated sludge at 150°C to reduce the moisture content to below 15%, grind, sieve, and retain the sludge particles with a particle size of 100-200 mesh;

[0048] Add an activator to the sludge granules, the activator is Zn...

Embodiment 3

[0052] The preparation of embodiment 3 sludge-based activated carbon

[0053] A preparation method of sludge-based activated carbon, comprising the steps of:

[0054] Add 2g of compound enzyme to 4kg of urban sludge with a water content of 45% (the compound enzyme is formed by mixing cellulase, protease, and chitinase in a mass ratio of 3:2:2), and stir at 35°C 18h to obtain enzymatic sludge;

[0055] Add earthworms to the enzymatic sludge (a total of 250g of earthworms with a body weight of 10-15g are added to each kilogram of enzymatic sludge), and under aerobic conditions (pass air into the enzymatic sludge at a flow rate of 1.5L / min) ) at 22°C for 3.5 days, take out the earthworms, and obtain the treated sludge;

[0056] Dry the treated sludge at 130°C to reduce the moisture content to below 15%, grind, sieve, and retain the sludge particles with a particle size of 100-200 mesh;

[0057] Add an activator to the sludge granules, the activator is ZnCl with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com