Curing agent with higher curing ability and use method thereof

A curing agent and capacity technology, applied in the field of solid waste treatment and resource utilization, can solve problems such as poor early strength, and achieve the effects of improving strength, facilitating preparation, and reducing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

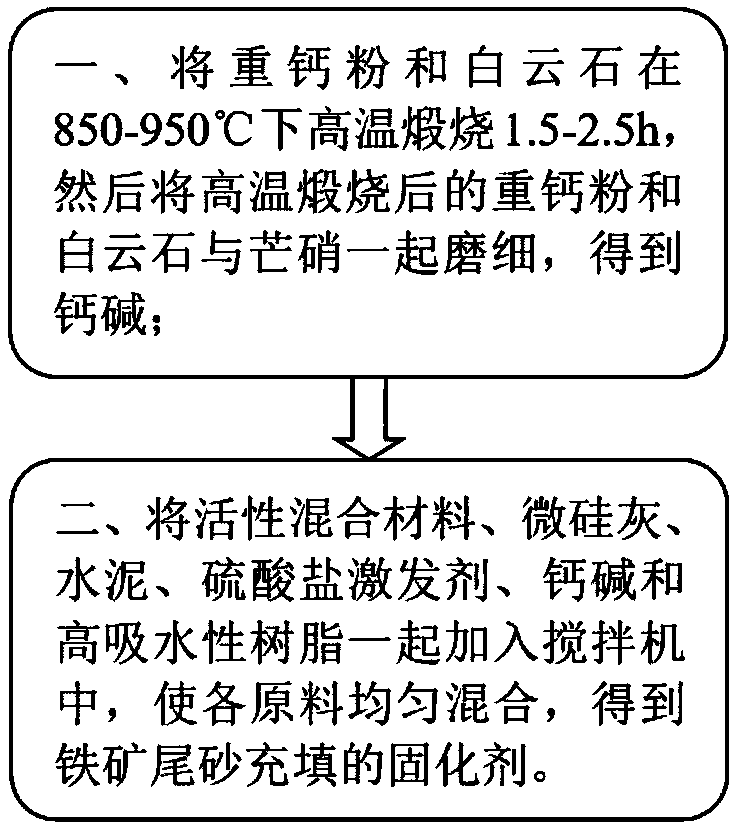

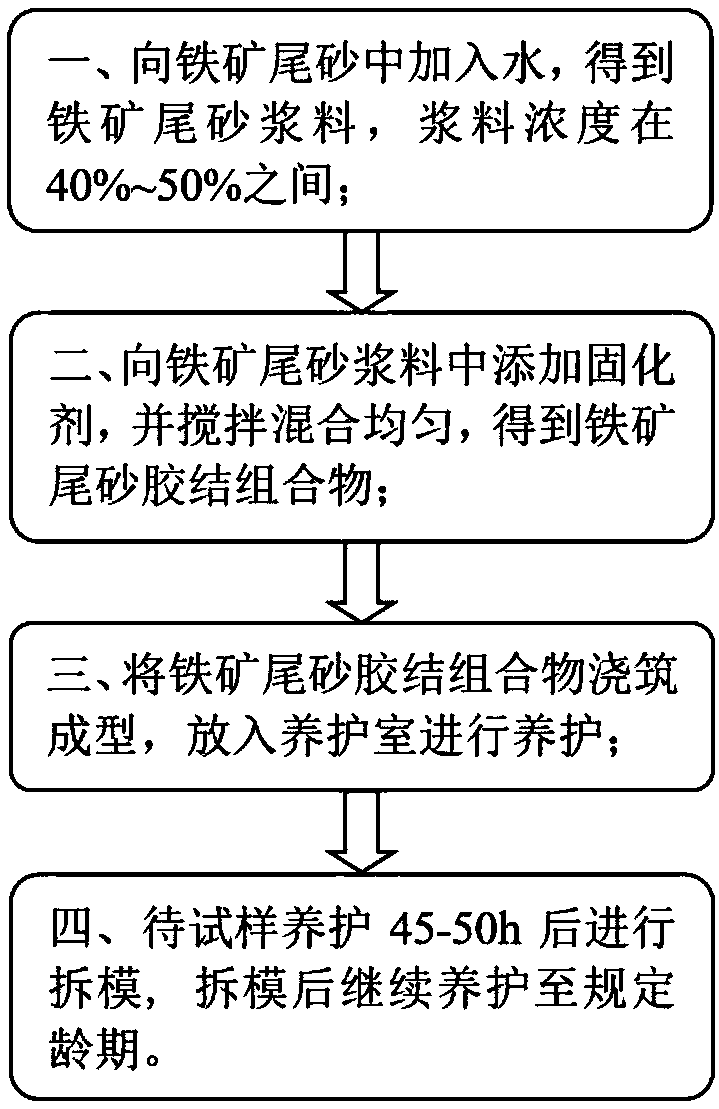

Method used

Image

Examples

Embodiment 1

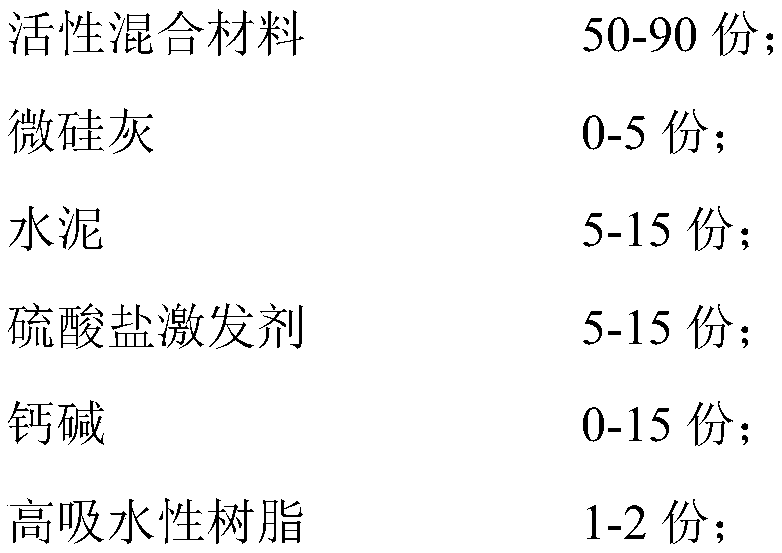

[0039] A kind of curing agent with stronger curing ability of the present embodiment comprises the following raw materials in parts by weight:

[0040]

[0041] Wherein the calcium base comprises 5 parts by mass of heavy calcium powder, 1 part by mass of dolomite and 1 part by mass of Glauber's salt;

[0042] 1 part of super absorbent resin.

[0043] In this embodiment, the active mixed material includes fly ash, and the specific surface area of the active mixed material is greater than or equal to 400m2 / kg.

[0044] Microsilica fume in this example is formed by rapid oxidation, condensation and precipitation of ferroalloy with air when ferrosilicon and industrial silicon are smelted, and the specific surface area is 20000m 2 / kg, fine silica fume particles, large specific surface area, can absorb a large amount of water in the initial stage of the reaction, and micro silica fume can react with calcium-alkaline hydration to generate Ca(OH) 2 Reaction to form gelled pro...

Embodiment 2

[0066] A kind of curing agent with strong curing ability of the present embodiment, its composition is basically the same as that of embodiment 1, further: include the following raw materials in parts by weight:

[0067]

[0068] Wherein the calcium base comprises 6 parts by mass of heavy calcium powder, 1.5 parts by mass of dolomite and 2 parts by mass of Glauber's salt;

[0069] 1.5 parts of super absorbent resin.

[0070] In this embodiment, the active mixed material includes granulated blast furnace slag and steel slag, and the specific surface area of micro silica fume is 22000m 2 / kg, cement includes Portland cement and aluminate cement, sulfate activator includes anhydrite and desulfurized gypsum.

[0071] In this embodiment, 6 parts by mass of heavy calcium powder and 1.5 parts by mass of dolomite were calcined at 880° C. for 2 hours at a high temperature, and then the calcined heavy calcium powder and dolomite were ground together with 2 parts by mass of Glauber...

Embodiment 3

[0082] A kind of curing agent with strong curing ability of the present embodiment, its composition is basically the same as that of embodiment 2, further: include the following raw materials in parts by weight:

[0083]

[0084] Wherein the calcium base comprises 7 mass parts of heavy calcium powder, 2 mass parts of dolomite and 3 mass parts of Glauber's salt;

[0085] 2 parts of super absorbent resin.

[0086] In this embodiment, the active mixed material includes granulated blast furnace slag and steel slag, and the specific surface area of micro silica fume is 26000m 2 / kg, cement includes ordinary Portland cement and aluminate cement, sulfate activator includes desulfurized gypsum and hemihydrate gypsum.

[0087] In this embodiment, 7 parts by mass of heavy calcium powder and 2 parts by mass of dolomite were calcined at 950°C for 2 hours at a high temperature, and then the calcined heavy calcium powder and dolomite were ground together with 3 parts by mass of Glaube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com