A kind of environment-friendly water-soluble paint and preparation method thereof

A water-soluble coating and environmental protection technology, applied in the field of coatings, can solve the problems of low flame retardant efficiency, poor heat resistance, environmental pollution, etc., and achieve the effect of improving flame retardant performance, good flame retardant effect, and promoting char formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention will be further described in detail below in conjunction with specific examples.

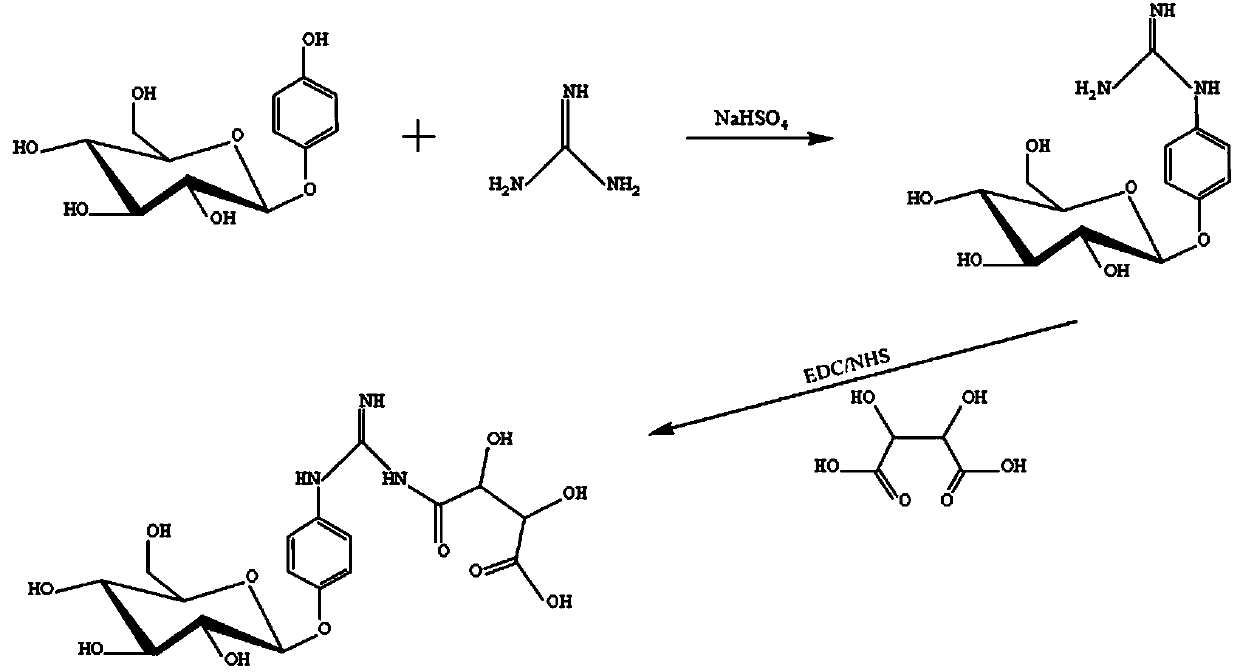

[0022] (1) Synthesis of flame retardant macromolecular functional fillers

[0023] Put 100ml of absolute ethanol as the reaction solution into a 250ml three-necked flask, and with the agitator running (rotating at 280r / min), add 10g of arbutin, 2g of guanidine, and then 1g of sodium bisulfite, and react for 3 hours. Filter, wash with absolute ethanol three times, and place the product in a vacuum oven to dry to obtain a white powder sample;

[0024] ② Put 80ml of a mixed solution of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and N-N-hydroxysuccinimide (NHS) in a 250ml three-necked flask as the reaction solution, In the case of starting the agitator (speed 250r / min), add 8g of the above white powder sample and tartaric acid in total, after stirring for 4 hours, take out the reaction solution, wash with methanol and deionized water for 3-4 times, and place...

Embodiment 2

[0028] (1) Synthesis of flame retardant macromolecular functional fillers

[0029] Put 100ml of absolute ethanol as the reaction solution into a 250ml three-necked flask, and with the agitator running (rotating at 280r / min), add 10g of arbutin, 2g of guanidine, and then 1g of sodium bisulfite, and react for 3 hours. Filter, wash with absolute ethanol three times, and place the product in a vacuum oven to dry to obtain a white powder sample;

[0030] ② Put 80ml of a mixed solution of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and N-N-hydroxysuccinimide (NHS) in a 250ml three-necked flask as the reaction solution, In the case of starting the agitator (speed 250r / min), add 8g of the above white powder sample and tartaric acid in total, after stirring for 4 hours, take out the reaction solution, wash with methanol and deionized water for 3-4 times, and place in a vacuum drying oven dry in medium to get the functional filler;

[0031] (2) Preparation of environmentall...

Embodiment 3

[0034] (1) Synthesis of flame retardant macromolecular functional fillers

[0035] Put 100ml of absolute ethanol as the reaction solution into a 250ml three-necked flask, and with the agitator running (rotating at 280r / min), add 10g of arbutin, 2g of guanidine, and then 1g of sodium bisulfite, and react for 3 hours. Filter, wash with absolute ethanol three times, and place the product in a vacuum oven to dry to obtain a white powder sample;

[0036] ② Put 80ml of a mixed solution of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC) and N-N-hydroxysuccinimide (NHS) in a 250ml three-necked flask as the reaction solution, In the case of starting the agitator (speed 250r / min), add 8g of the above white powder sample and tartaric acid in total, after stirring for 4 hours, take out the reaction solution, wash with methanol and deionized water for 3-4 times, and place in a vacuum drying oven dry in medium to get the functional filler;

[0037] (2) Preparation of environmentall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com