System and method for preparing high-purity tetrabutylammonium hydrogen sulfate through electrolysis process

A technology of tetrabutylammonium bisulfate and electrolysis, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc. It can solve the problems that the sediment is not easy to handle and utilize, the preparation method is not very mature, and the amount of metal in the electrode is large. , to achieve the effects of low pollution, high yield and purity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

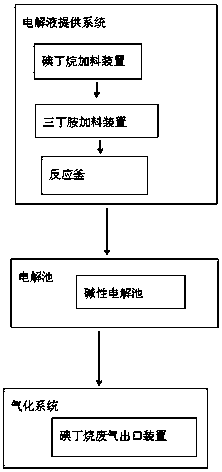

[0019] see figure 1 A system for preparing high-purity tetrabutylammonium bisulfate by electrolysis in the present invention includes an electrolyte supply system, an electrolytic cell and a gasification system, the outlet of the electrolyte supply system is connected with the electrolyte inlet of the electrolytic cell, and the cathode hydrogen gas outlet of the electrolytic cell Connect with gasification system inlet.

[0020] The electrolyte supply system of this embodiment includes a reactor, and the reactor communicates with the iodobutane feeding device and the tributylamine feeding device.

[0021] The electrolytic cell of this embodiment is an alkaline electrolytic cell, and the cathode and anode catalyst materials are Co.

[0022] The gasification system in this embodiment is an iodobutane waste gas outlet device.

[0023] The present invention also provides a kind of method that system carries out electrolysis to prepare high-purity tetrabutylammonium bisulfate, com...

Embodiment 2

[0028] see figure 1 A system for preparing high-purity tetrabutylammonium bisulfate by electrolysis in the present invention includes an electrolyte supply system, an electrolytic cell and a gasification system, the outlet of the electrolyte supply system is connected with the electrolyte inlet of the electrolytic cell, and the cathode hydrogen gas outlet of the electrolytic cell Connect with gasification system inlet.

[0029] The electrolyte supply system of this embodiment includes a reactor, and the reactor communicates with the iodobutane feeding device and the tributylamine feeding device.

[0030] The electrolytic cell of this embodiment is an alkaline electrolytic cell, and the cathode and anode catalyst materials are Fe.

[0031] The gasification system in this embodiment is an iodobutane waste gas outlet device.

[0032] The present invention also provides a kind of method that system carries out electrolysis to prepare high-purity tetrabutylammonium bisulfate, com...

Embodiment 3

[0037] see figure 1 A system for preparing high-purity tetrabutylammonium bisulfate by electrolysis in the present invention includes an electrolyte supply system, an electrolytic cell and a gasification system, the outlet of the electrolyte supply system is connected with the electrolyte inlet of the electrolytic cell, and the cathode hydrogen gas outlet of the electrolytic cell Connect with gasification system inlet.

[0038] The electrolyte supply system of this embodiment includes a reactor, and the reactor communicates with the iodobutane feeding device and the tributylamine feeding device.

[0039] The electrolytic cell of this embodiment is an alkaline electrolytic cell, and the cathode and anode catalyst materials are Ru.

[0040] The gasification system in this embodiment is an iodobutane waste gas outlet device.

[0041] The present invention also provides a kind of method that system carries out electrolysis to prepare high-purity tetrabutylammonium bisulfate, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com