Carbon nanotube limited range selenium composite anode material and preparation method thereof

A technology of composite cathode material and carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

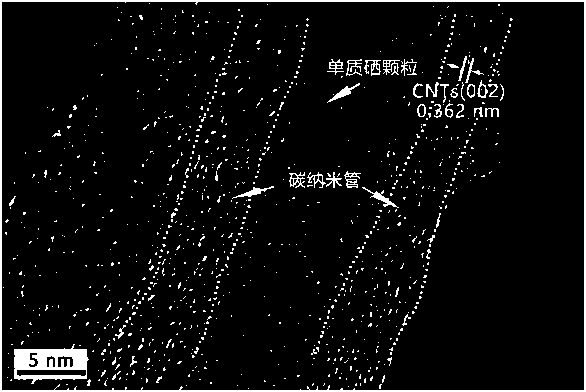

[0033] In the composite positive electrode material, the elemental selenium nanoparticles are confined in the one-dimensional nanospace of the carbon nanotubes with a mass ratio of 4:1; the diameter of the carbon nanotubes is 5-20nm; the elemental selenium nanoparticles The particle size is 5-10 nm, and the elemental selenium nanoparticles are smaller than the diameter of the confined carbon nanotubes.

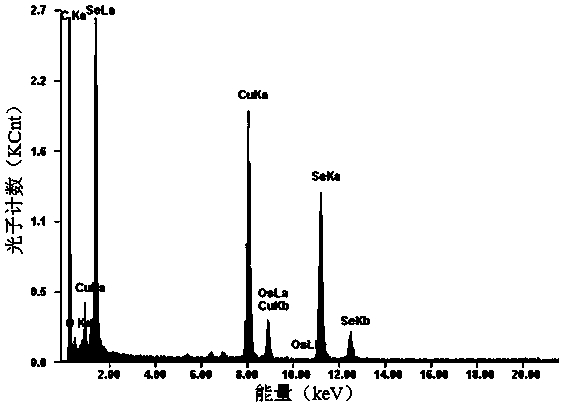

[0034] Such as figure 1 As shown, the carbon nanotube-confined selenium composite positive electrode material of the embodiment of the present invention contains selenium and carbon elements, and does not contain impurities (during EDS detection, the sample is placed on a copper micro-grid, so it shows copper elements, not impurities).

[0035] Such as figure 2 As shown, in the carbon nanotube-confined selenium composite positive electrode material of the embodiment of the present invention, the carbon nanotubes are evenly distributed without agglomeration, and the diameter ...

Embodiment 2

[0043] In the composite positive electrode material, the elemental selenium nanoparticles are confined in the one-dimensional nanospace of the carbon nanotubes with a mass ratio of 3:2; the diameter of the carbon nanotubes is 20-25nm; the elemental selenium nanoparticles The particle size of the selenium is 10-15nm, and the nanometer particle of the elemental selenium is smaller than the diameter of the confined carbon nanotube.

[0044] After testing, the carbon nanotube-confined selenium composite positive electrode material of the embodiment of the present invention contains selenium and carbon elements, and does not contain impurities.

[0045] After testing, in the carbon nanotube-confined selenium composite positive electrode material of the embodiment of the present invention, the carbon nanotubes are evenly distributed without agglomeration, and the diameter of the carbon nanotubes is 20-25 nm.

[0046] After testing, in the carbon nanotube-confined selenium composite ...

Embodiment 3

[0053] In the composite positive electrode material, the elemental selenium nanoparticles are confined in the one-dimensional nanospace of the carbon nanotubes with a mass ratio of 2:3; the diameter of the carbon nanotubes is 25-30 nm; the elemental selenium nanoparticles The particle size of the particles is 15-20 nm, and the elemental selenium nanoparticles are smaller than the diameter of the confined carbon nanotubes.

[0054] After testing, the carbon nanotube-confined selenium composite positive electrode material of the embodiment of the present invention contains selenium and carbon elements, and does not contain impurities.

[0055] After testing, in the carbon nanotube-confined selenium composite cathode material of the embodiment of the present invention, the carbon nanotubes are evenly distributed without agglomeration, and the diameter of the carbon nanotubes is 25-30 nm.

[0056] After testing, in the carbon nanotube-confined selenium composite positive electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com