Preparation process of a flexible electrode with long cycle life and high specific capacity

A high specific capacity, flexible electrode technology, applied in the direction of battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of complex and cumbersome preparation methods, short cycle life, and low energy density, and achieve simple and easy process, long-term Effect of cycle life and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

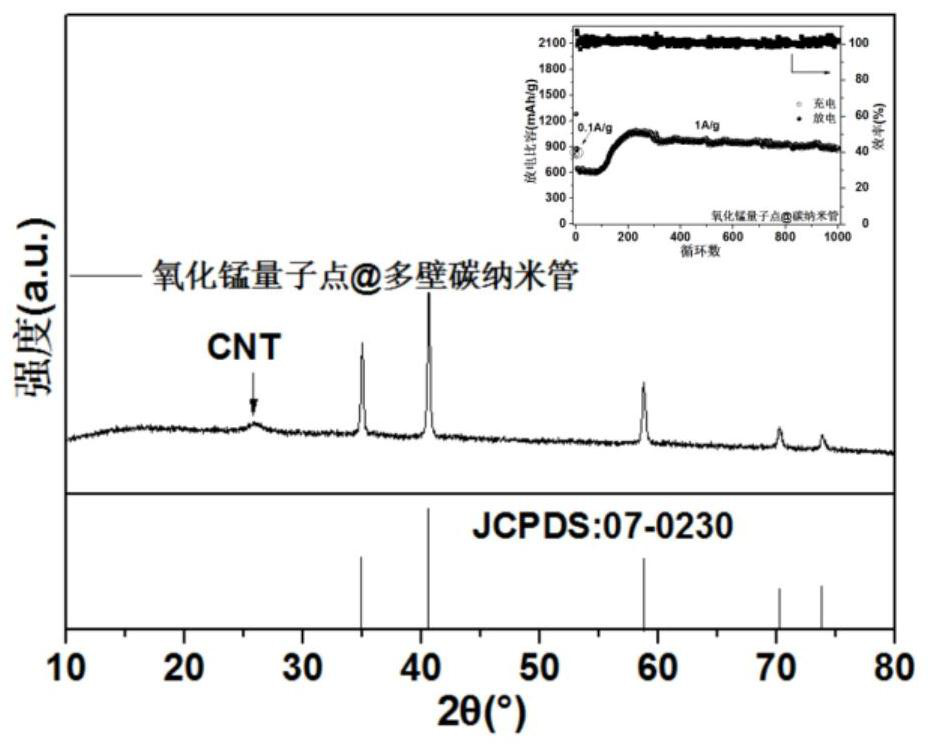

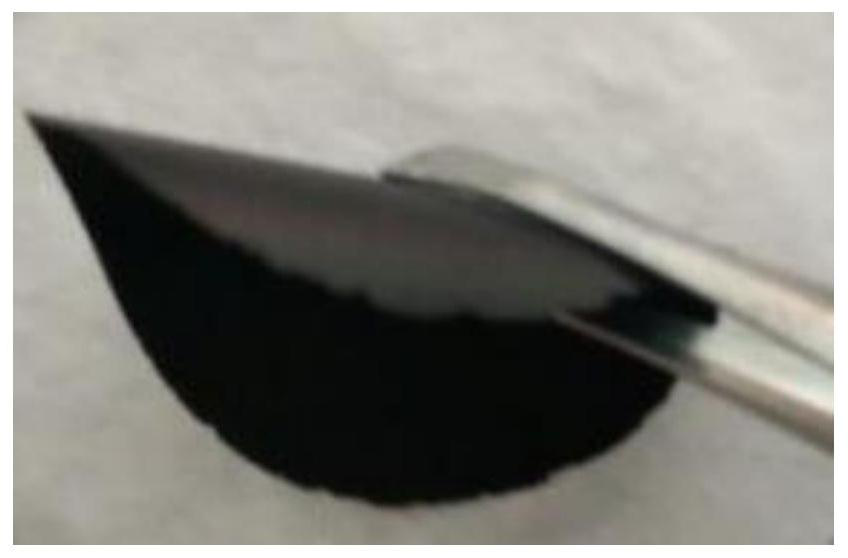

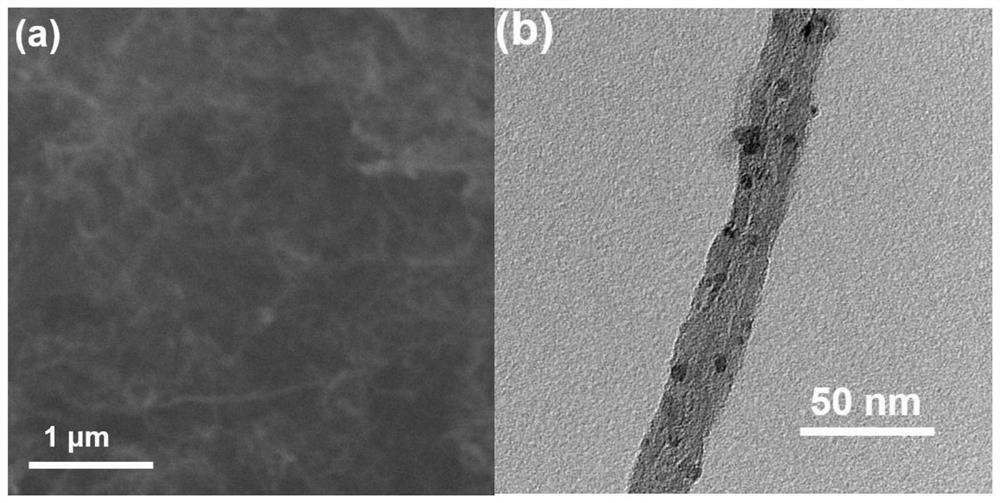

[0032] Weigh 300mg of commercial multi-walled carbon nanotubes and put them into a sand core, put the sand core and 5ml of concentrated nitric acid into the reaction kettle and put them into the iron shell, then transfer them to a hydrothermal furnace for acidification treatment at 200°C for 2 hours, and the acidified multi-walled carbon nanotubes The carbon nanotubes are cleaned and dried. Weigh 40 mg of acid-treated multi-walled carbon nanotubes and 1 mmol of manganese sulfate hexahydrate into a beaker, add 50 ml of water for stirring, pulverization and ultrasonication to fully disperse them, stir for 1 hour, add 3 mmol of ammonium bicarbonate, and Stirring was continued for 3 hours, followed by vacuum filtration and vacuum freeze-drying, and the obtained flexible film was annealed in a tube furnace at 600°C for 3 hours in argon to form a flexible composite electrode of manganese oxide quantum dots and multi-walled carbon nanotubes.

[0033] The specific properties of the pr...

Embodiment 2

[0042] Weigh 300mg of commercial multi-walled carbon nanotubes and put them into a sand core, put the sand core and 5ml of concentrated nitric acid into the reaction kettle and put them into the iron shell, then transfer them to a hydrothermal furnace for acidification treatment at 200°C for 2 hours, and the acidified multi-walled carbon nanotubes The carbon nanotubes are cleaned and dried. Weigh 40 mg of acid-treated multi-walled carbon nanotubes and 1 mmol of manganese sulfate hexahydrate into a beaker, add 50 ml of water for stirring, pulverization and ultrasonication to make it fully dispersed, and after stirring for 1 hour, add 3 mmol of ammonium bicarbonate, Stirring was continued at 0°C for 3 hours, followed by vacuum filtration and vacuum freeze-drying, and the obtained flexible film was annealed in a tube furnace at 700°C in argon for 4 hours to form a flexible composite of manganese oxide quantum dots and multi-walled carbon nanotubes electrode.

[0043] Specific pr...

Embodiment 3

[0045] Weigh 300mg of commercial multi-walled carbon nanotubes and put them into a sand core, put the sand core and 5ml of concentrated nitric acid into the reaction kettle and put them into the iron shell, then transfer them to a hydrothermal furnace for acidification treatment at 200°C for 2 hours, and the acidified multi-walled carbon nanotubes The carbon nanotubes are cleaned and dried. Weigh 40 mg of acid-treated multi-walled carbon nanotubes and 1 mmol of manganese sulfate hexahydrate into a beaker, add 50 ml of water for stirring, pulverization and ultrasonication to make it fully dispersed, and after stirring for 1 hour, add 3 mmol of ammonium bicarbonate, Stirring was continued at 0°C for 4 hours, followed by vacuum filtration and vacuum freeze-drying, and the obtained flexible film was annealed in a tube furnace at 600°C for 3 hours to form a flexible composite of manganese oxide quantum dots and multi-walled carbon nanotubes electrode.

[0046] The specific propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com