Carbon-assembled copper sulfide hollow nanocube honeycomb material and its preparation and application

A technology of hollow nano and honeycomb materials, applied in the field of lithium-ion batteries, to achieve the effect of strengthening structural strength, high electrochemical performance, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

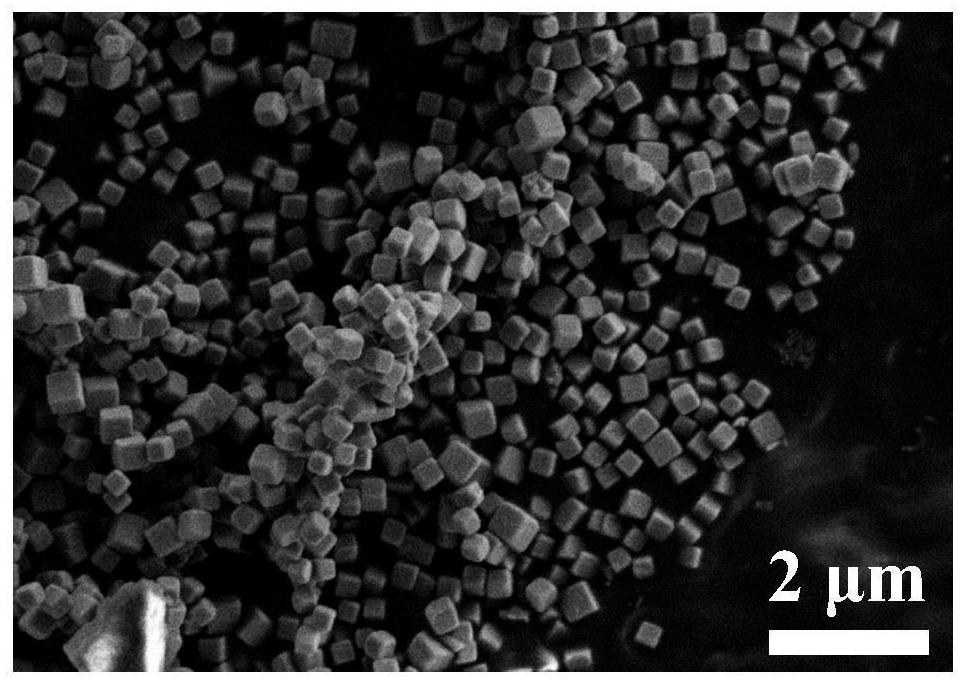

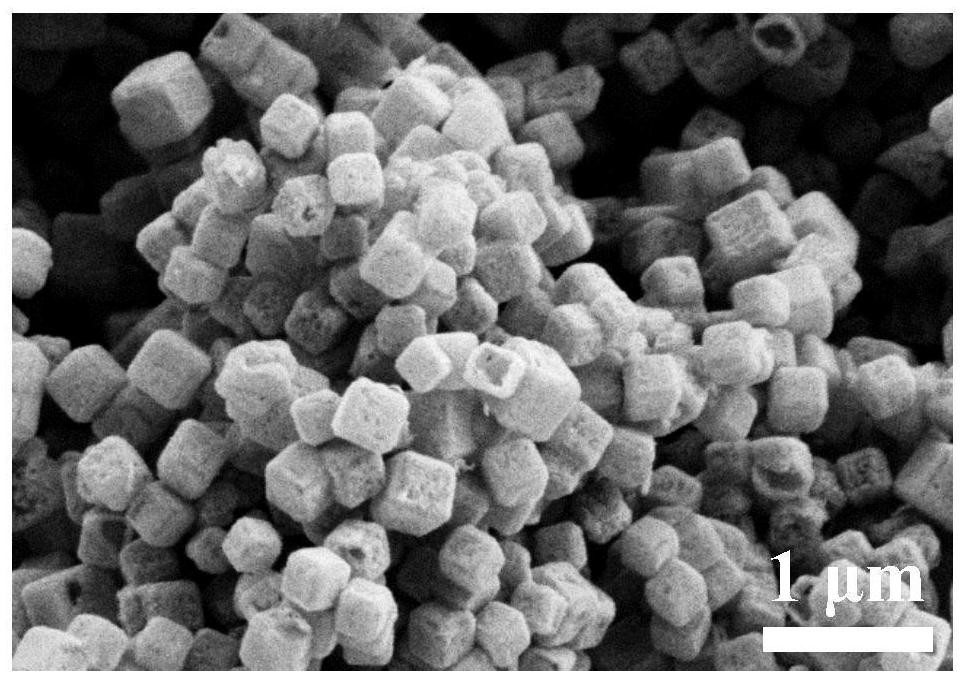

Embodiment 1

[0042] (1) First, dissolve 0.38g of copper sulfate pentahydrate and 0.15g of sodium citrate in 80mL of deionized water; then dissolve 1g of NaOH in 20mL of deionized water, add the NaOH solution to the aforementioned solution, and stir for 3 minutes; then add 0.26g of ascorbic acid Dissolve in 50mL deionized water, add ascorbic acid solution to the above solution, and stir at room temperature for 1h; the product is washed with water and ethanol several times after centrifugation to obtain Cu 2 O cube;

[0043] (2) Take the 0.04g Cu prepared by step (1) 2 O cube material, dispersed in 30mL deionized water; 0.03gNa 2 S·9H 2 O was dissolved in 20 mL deionized water, and the Na 2 S solution was added to the above solution, stirred for 30min, and the product was washed three times with deionized water after centrifugation, and then immediately dispersed in a mixed solution of 20mL deionized water and 20mL ethanol, stirred for 30min; 3.97g Na 2 S 2 o 3 ·5H 2 O was dissolved i...

Embodiment 2

[0052] (1) First, dissolve 0.38g of copper sulfate pentahydrate and 0.15g of sodium citrate in 80mL of deionized water; then dissolve 1g of NaOH in 20mL of deionized water, add the NaOH solution to the aforementioned solution, and stir for 3 minutes; then add 0.26g of ascorbic acid Dissolve in 50mL deionized water, add ascorbic acid solution to the above solution, and stir at room temperature for 1h; the product is washed with water and ethanol several times after centrifugation to obtain Cu 2 O cube;

[0053] (2) Take the 0.04g Cu prepared by step (1) 2 O cube material, dispersed in 30mL deionized water; 0.03gNa 2 S·9H 2 O was dissolved in 20 mL deionized water, and the Na 2 S solution was added to the above solution, stirred for 30min, the product was centrifuged and washed 3 times with deionized water, then immediately dispersed in a mixed solution of 20mL deionized water and 20mL ethanol, stirred for 30min; 2g Na 2 S 2 o 3 ·5H 2 O was dissolved in 16 mL deionized wa...

Embodiment 3

[0058] (1) First, dissolve 0.38g of copper sulfate pentahydrate and 0.15g of sodium citrate in 80mL of deionized water; then dissolve 2g of NaOH in 20mL of deionized water, add the NaOH solution to the aforementioned solution, and stir for 3 minutes; then add 0.26g of ascorbic acid Dissolve in 50mL deionized water, add ascorbic acid solution to the above solution, and stir at room temperature for 1h; the product is washed with water and ethanol several times after centrifugation to obtain Cu 2 O cube;

[0059] Subsequent process is identical with embodiment 1.

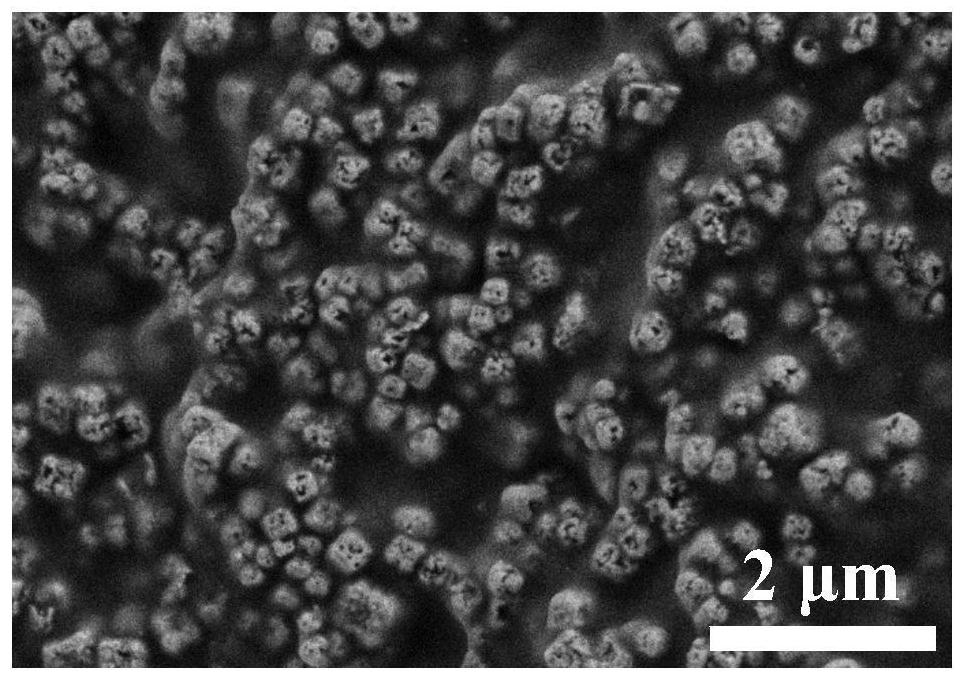

[0060] The structure of the product carbon-assembled copper sulfide hollow nanocube honeycomb material is similar to Example 1, the main difference is that the side length of the hollow nanocube becomes 200-300nm, and the wall thickness is about 70nm.

[0061] Adopt the same process as in Example 1 to make the negative electrode of lithium ion battery, assemble into lithium ion battery, with current density 0.1A g -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com