Preparation method and application of nitrogen-doped carbon nano fiber compound zinc oxide lithium ion battery cathode material

A technology of lithium-ion batteries and nanofibers, applied in the direction of battery electrodes, fiber chemical characteristics, negative electrodes, etc., can solve the problems of poor conductivity, volume expansion, etc., and achieve the effects of good fiber dispersion, reduced agglomeration, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

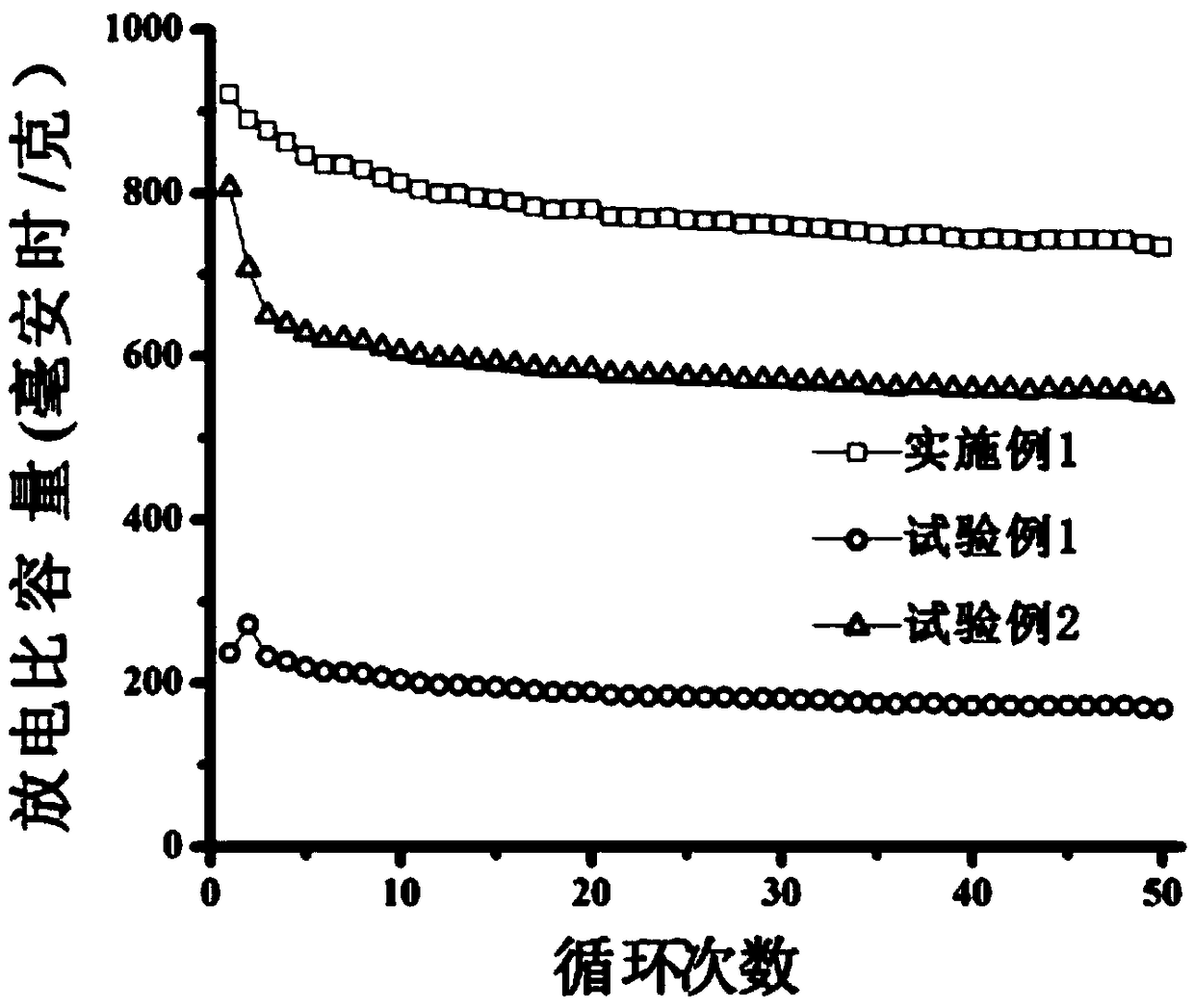

Embodiment 1

[0026] (1) Preparation of polyacrylonitrile fiber:

[0027] Mix 1.5 g of polyacrylonitrile and 15 mL of dimethylformamide evenly, place on a magnetic stirrer and stir for 18 hours to obtain an electrospinning precursor solution, and then use an electrospinning machine to prepare polyacrylonitrile fibers for use.

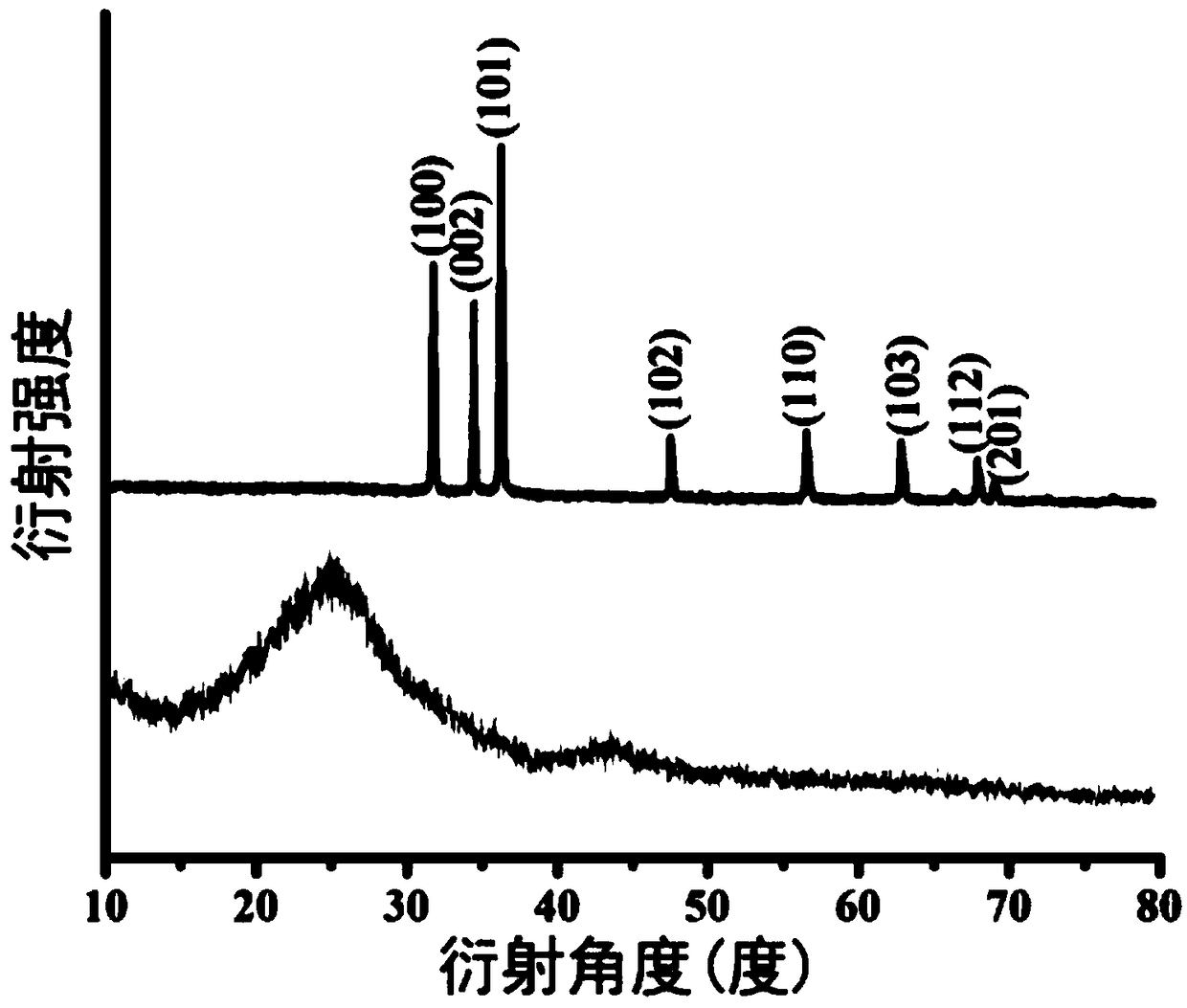

[0028] (2) Preparation of nitrogen-doped carbon nanofibers:

[0029] The polyacrylonitrile fibers prepared in step (1) were placed in a tube furnace, and calcined at 800° C. for 4 hours under a nitrogen atmosphere to obtain nitrogen-doped carbon nanofibers.

[0030] (3) Preparation of zinc oxide / nitrogen-doped carbon nanofibers:

[0031] Put 0.8 g of nitrogen-doped carbon nanofibers prepared in step (2) into 200 mL of deionized water, then add 1.5 g of zinc chloride and 1.5 g of hexamethylenetetramine, stir evenly, and heat in a water bath at 80°C for 8 hours to obtain oxidation Zinc / nitrogen doped carbon nanofibers.

[0032] The nitrogen-doped carbon nanofiber co...

Embodiment 2

[0036] (1) Preparation of polyacrylonitrile fiber:

[0037] Mix 1 g of polyacrylonitrile and 10 mL of dimethylformamide evenly, place on a magnetic stirrer and stir for 12 hours to obtain an electrospinning precursor solution, and then use an electrospinning machine to prepare polyacrylonitrile fibers for use.

[0038] (2) Preparation of nitrogen-doped carbon nanofibers:

[0039] The polyacrylonitrile fibers prepared in step (1) were placed in a tube furnace, and calcined at 700° C. for 3 hours under a nitrogen atmosphere to obtain nitrogen-doped carbon nanofibers.

[0040] (3) Preparation of zinc oxide / nitrogen-doped carbon nanofibers:

[0041] Put 0.5 g of nitrogen-doped carbon nanofibers prepared in step (2) into 100 mL of deionized water, then add 1 g of zinc chloride and 1 g of hexamethylenetetramine, stir evenly, and heat in a water bath at 60 °C for 6 hours to obtain zinc oxide / Nitrogen-doped carbon nanofibers.

Embodiment 3

[0043](1) Preparation of polyacrylonitrile fiber:

[0044] Mix 2 g of polyacrylonitrile and 20 mL of dimethylformamide evenly, place on a magnetic stirrer and stir for 24 hours to obtain an electrospinning precursor solution, and then use an electrospinning machine to prepare polyacrylonitrile fibers for use.

[0045] (2) Preparation of nitrogen-doped carbon nanofibers:

[0046] The polyacrylonitrile fibers prepared in step (1) were placed in a tube furnace, and calcined at 900° C. for 6 hours under a nitrogen atmosphere to obtain nitrogen-doped carbon nanofibers.

[0047] (3) Preparation of zinc oxide / nitrogen-doped carbon nanofibers:

[0048] Put 1 g of nitrogen-doped carbon nanofibers prepared in step (2) in 200 mL of deionized water, then add 2 g of zinc chloride and 2 g of hexamethylenetetramine, stir evenly, and heat in a water bath at 90°C for 12 hours to obtain zinc oxide / nitrogen doped with carbon nanofibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com