Preparation method of HNTs plasticized PAN/P(LLA-EG-MA) polymer electrolyte and product thereof

A LLA-EG-MA, polymer technology, applied in the field of preparation of HNTs plasticized PAN/P polymer electrolyte, can solve problems affecting the electrochemical stability and safety of batteries, uneven distribution of polymer membrane pores, difficult To ensure that the solvent is removed and other problems, to achieve the effect of improving electrochemical performance, uniform thickness and fiber diameter size distribution, and increasing shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of this kind of HNTs plasticized PAN / P (LLA-EG-MA) biogel polymer electrolyte provided by the invention comprises the following steps:

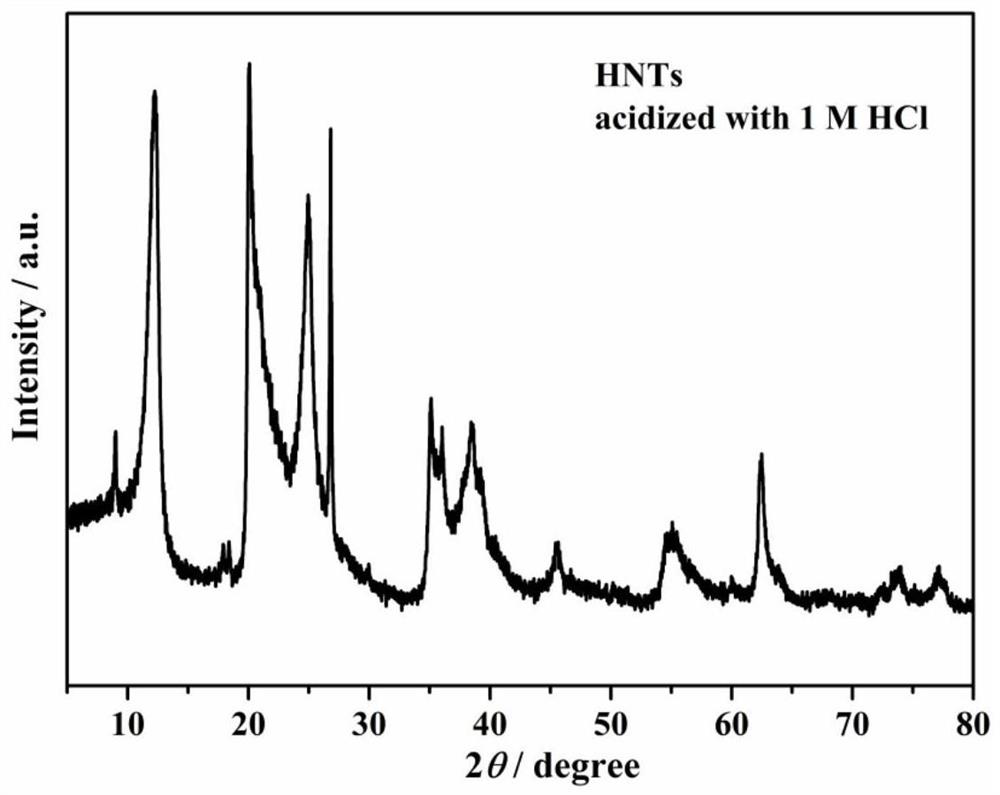

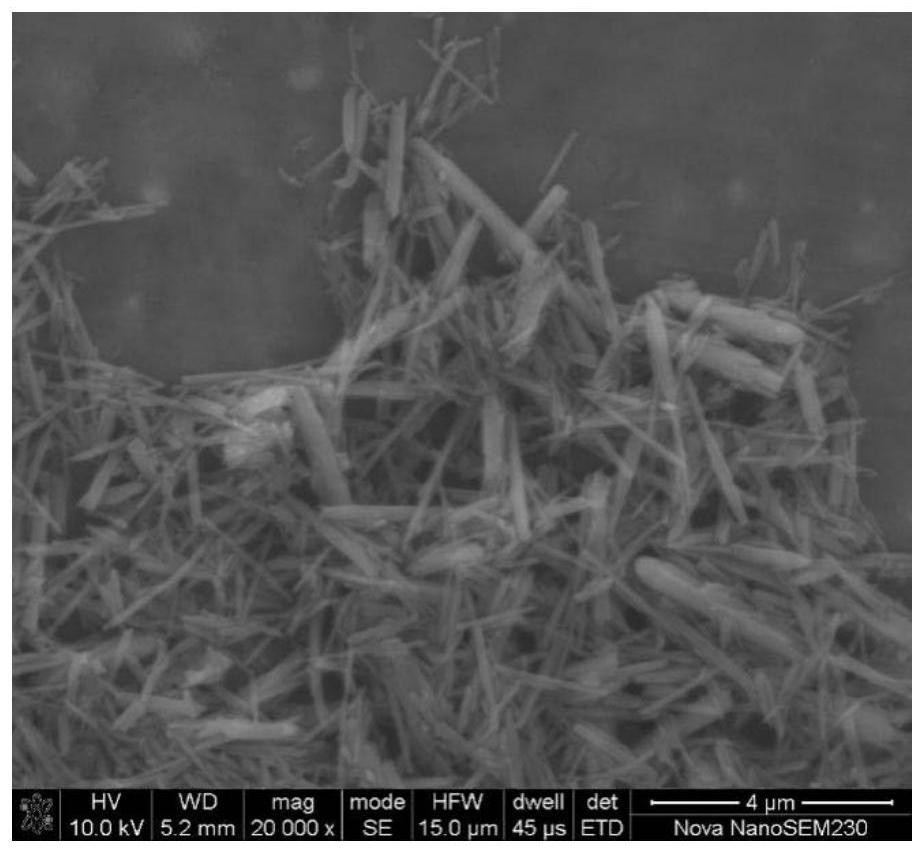

[0038] (1) Weigh 1g of HNTs and add it to 500ml of 1M HCl solution, stir at room temperature for 12h, centrifuge, test the pH value of the supernatant after centrifugation, until the pH of the supernatant is 6, put the acidified HNTs under vacuum at 60°C Dry for 12 hours;

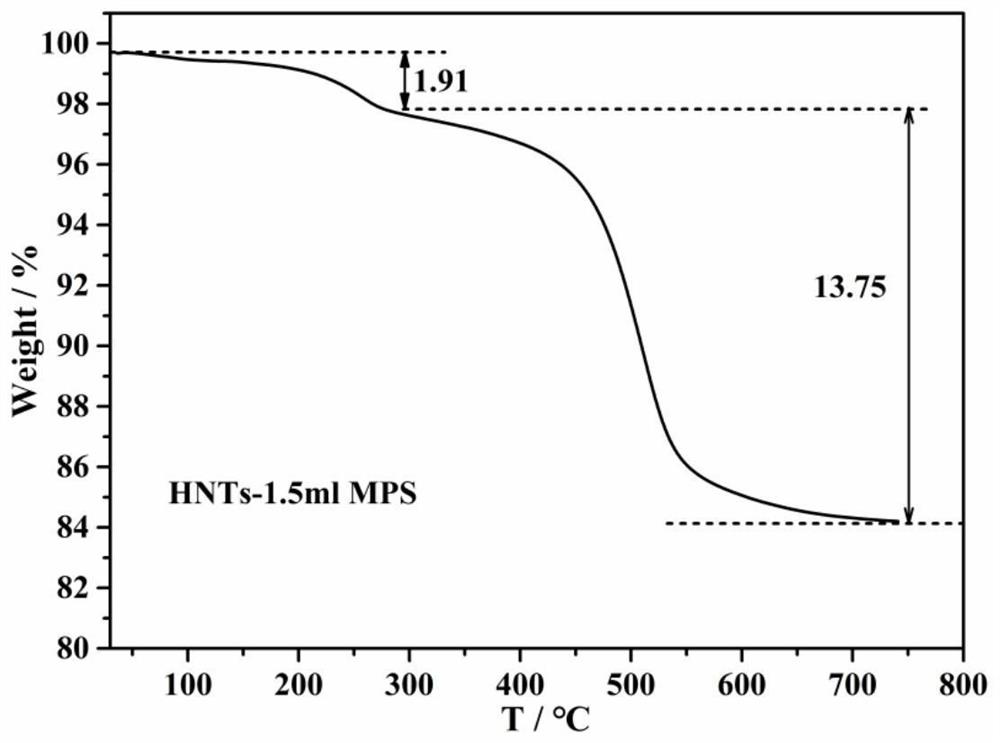

[0039] (2) Weigh 0.2g of the acidified HNTs powder in step (1) and add it to 50ml of deionized water, stir at room temperature to obtain a milky white HNTs suspension, and add 1.5ml of 3-(methacryloyloxy)propyltrimethoxysilane (MPS ) adding HNTs suspension under stirring condition, transferring to Erlenmeyer flask, condensing and reflux reaction at 80°C and 250r / min for 4h;

[0040] (3) Centrifugally wash the HNTs-MPS milky white solution obtained in step (2) with absolute ethanol and deionized water several times, and dry it in a vacuum oven at 60°...

Embodiment 2

[0050] The preparation of this kind of HNTs plasticized PAN / P (LLA-EG-MA) biogel polymer electrolyte provided by the invention comprises the following steps:

[0051] (1) Weigh 1g of HNTs and add it to 500ml of 1M HCl solution, stir at room temperature for 30h, centrifuge, test the pH value of the supernatant after centrifugation, until the pH of the supernatant is 7, put the acidified HNTs under vacuum at 60°C Dry for 18 hours;

[0052] (2) Weigh 0.2g of the acidified HNTs powder in step (1) and add it to 50ml of deionized water, stir at room temperature to obtain a milky white HNTs suspension, and add 2ml of 3-(methacryloyloxy)propyltrimethoxysilane (MPS) Add the HNTs suspension under the condition of stirring, transfer to the Erlenmeyer flask, condense and reflux for 8 hours under the condition of 100°C and 250r / min;

[0053] (3) Centrifugally wash the HNTs-MPS milky white solution obtained in step (2) with absolute ethanol and deionized water several times, and dry it in ...

Embodiment 3

[0062] The preparation of this kind of HNTs plasticized PAN / P (LLA-EG-MA) biogel polymer electrolyte provided by the invention comprises the following steps:

[0063] (1) Weigh 1g of HNTs and add it to 500ml of 1M HCl solution, stir at room temperature for 48h, centrifuge, test the pH value of the supernatant after centrifugation, until the pH of the supernatant is 7, put the acidified HNTs under vacuum at 60°C Dry for 24 hours;

[0064] (2) Weigh 0.2g of the acidified HNTs powder in step (1) and add it to 50ml of deionized water, stir at room temperature to obtain a milky white HNTs suspension, and add 3ml of 3-(methacryloyloxy)propyltrimethoxysilane (MPS) Add the HNTs suspension under stirring condition, transfer to the Erlenmeyer flask, condense and reflux reaction at 120°C and 250r / min for 12h;

[0065] In the step (1), the concentration of hydrochloric acid is 0.5-1.5M, the concentration of HNTs in hydrochloric acid is 1-3g / L; the setting time is 12-48h, the drying tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com