A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low utilization rate of electrode active materials, poor battery cycle performance, poor cycle stability, etc., to achieve enhanced electrochemical performance, improvement of adsorption energy, and enhancement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

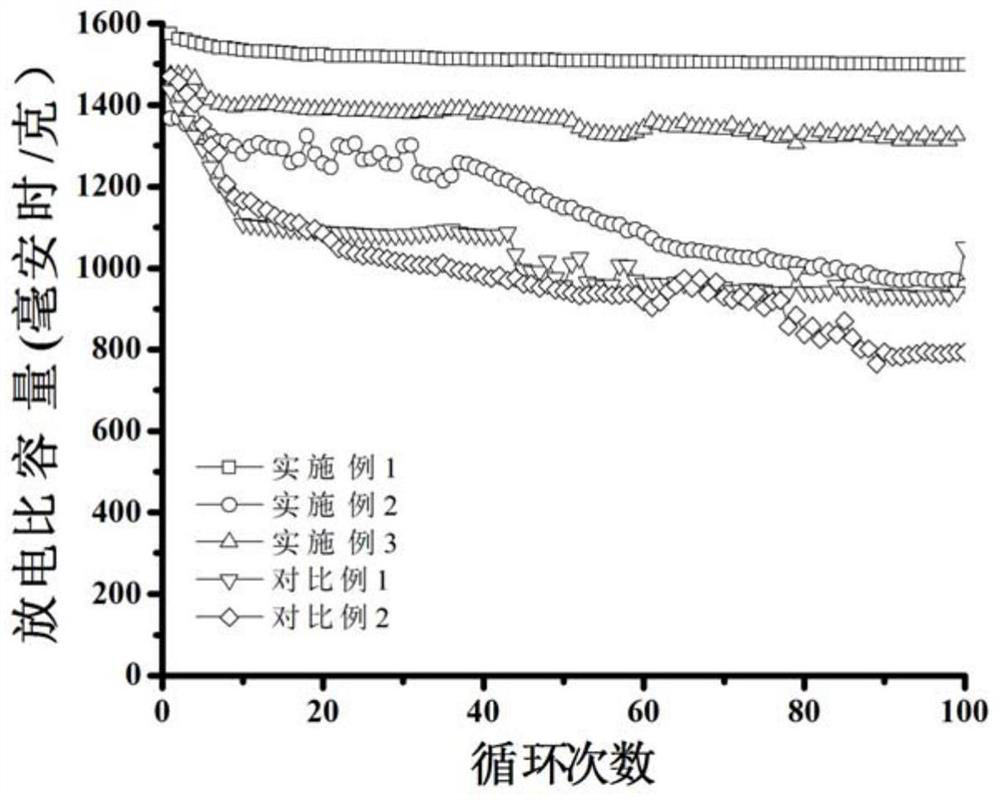

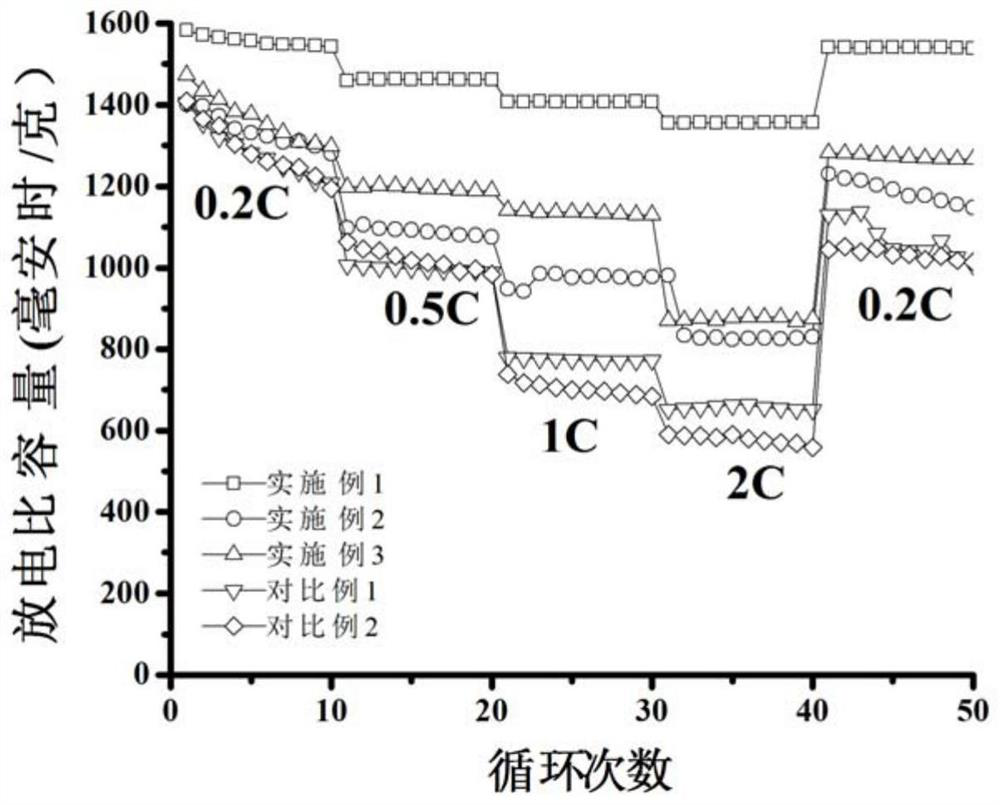

Embodiment 1

[0022] The anode material of the lithium-sulfur battery is a composite material formed of nitrogen-doped carbon nanofiber-carbonized covalent organic framework material and pure-phase nano-sulfur powder.

[0023] The mass ratio of the nitrogen-doped carbon nanofiber-carbonized covalent organic framework material to the pure-phase nano-sulfur powder is 1:3.

[0024] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0025] (1) Preparation of covalent organic framework materials: 0.8g of 1,4-phenylenediamine and 0.8g of 1,3,5-tritylaldehyde were placed in a reaction tube, and 8mL of 1,4-dioxane was added to dissolve the two Mix well, then slowly add 3mL of acetic acid with a mass fraction of 30%, a yellow solid will be produced immediately with the dripping of acetic acid, connect the reaction tube to the vacuum line, vacuumize under the condition of liquid nitrogen freezing, drive out the air bubbles, and sea...

Embodiment 2

[0031] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0032](1) Preparation of covalent organic framework materials: put 0.5g of 1,4-phenylenediamine and 0.5g of 1,3,5-tritylaldehyde in a reaction tube, add 5mL of 1,4-dioxane to dissolve them Mix well, then slowly add 1mL of acetic acid with a mass fraction of 10%, a yellow solid will be produced immediately with the addition of acetic acid, connect the reaction tube to the vacuum line, vacuumize under the condition of liquid nitrogen freezing, drive out the air bubbles, and seal the tube , naturally rose to room temperature, then transferred to a constant temperature oven at 100°C to react for 24 hours, stopped heating, and after the system was cooled to room temperature, opened the reaction tube, centrifuged, washed, and after Soxhlet extraction, vacuum-dried at 60°C for 12 hours. A light yellow solid was obtained;

[0033] (2) Preparation of nitrogen...

Embodiment 3

[0039] The preparation method of the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0040] (1) Preparation of covalent organic framework materials: put 1g of 1,4-phenylenediamine and 1g of 1,3,5-tritylaldehyde in a reaction tube, add 10mL of 1,4-dioxane to dissolve and mix them well , then drop 5mL of acetic acid with a mass fraction of 40%, a yellow solid will be produced immediately with the drop of acetic acid, connect the reaction tube to the vacuum line, vacuumize under the condition of liquid nitrogen freezing, drive out the air bubbles, seal the tube, and rise naturally to room temperature, then transferred to a constant temperature oven at 150°C to react for 48 hours, stop heating, and after the system was cooled to room temperature, open the reaction tube, centrifuge, wash, and after Soxhlet extraction, vacuum-dry at 60°C for 24 hours to obtain light yellow solid;

[0041] (2) Preparation of nitrogen-doped carbon nanofiber-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com