Preparation method of high-rate lithium ion ternary cathode material

A cathode material, lithium ion technology, applied in the field of cathode materials for lithium ion batteries and their preparation, and can solve the problems of low conductivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

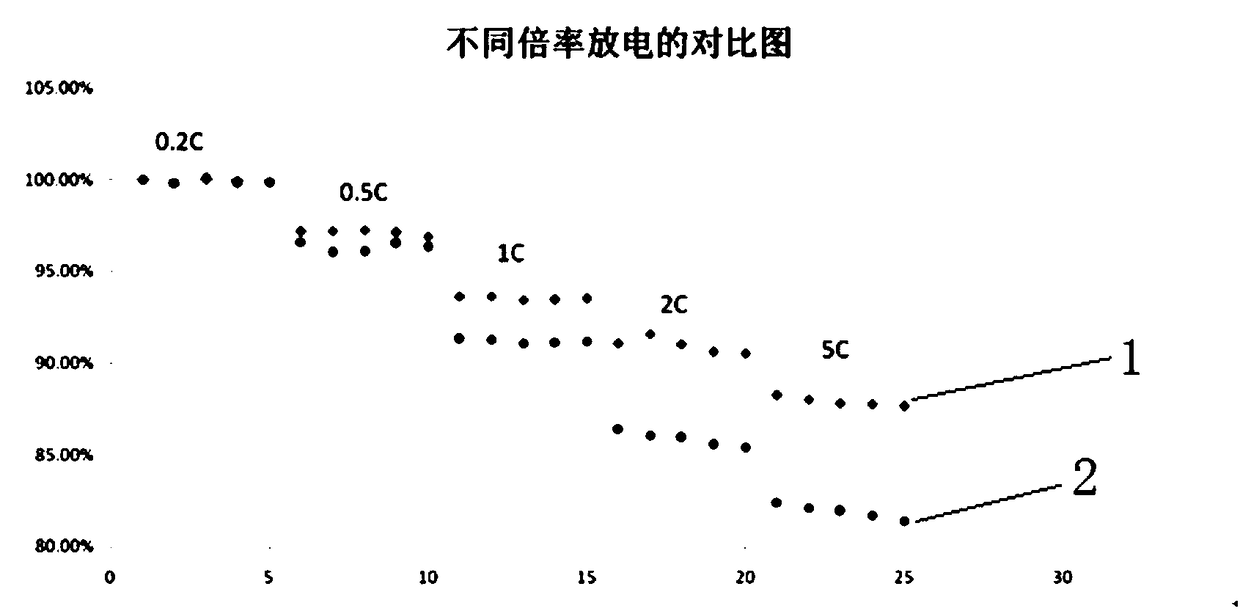

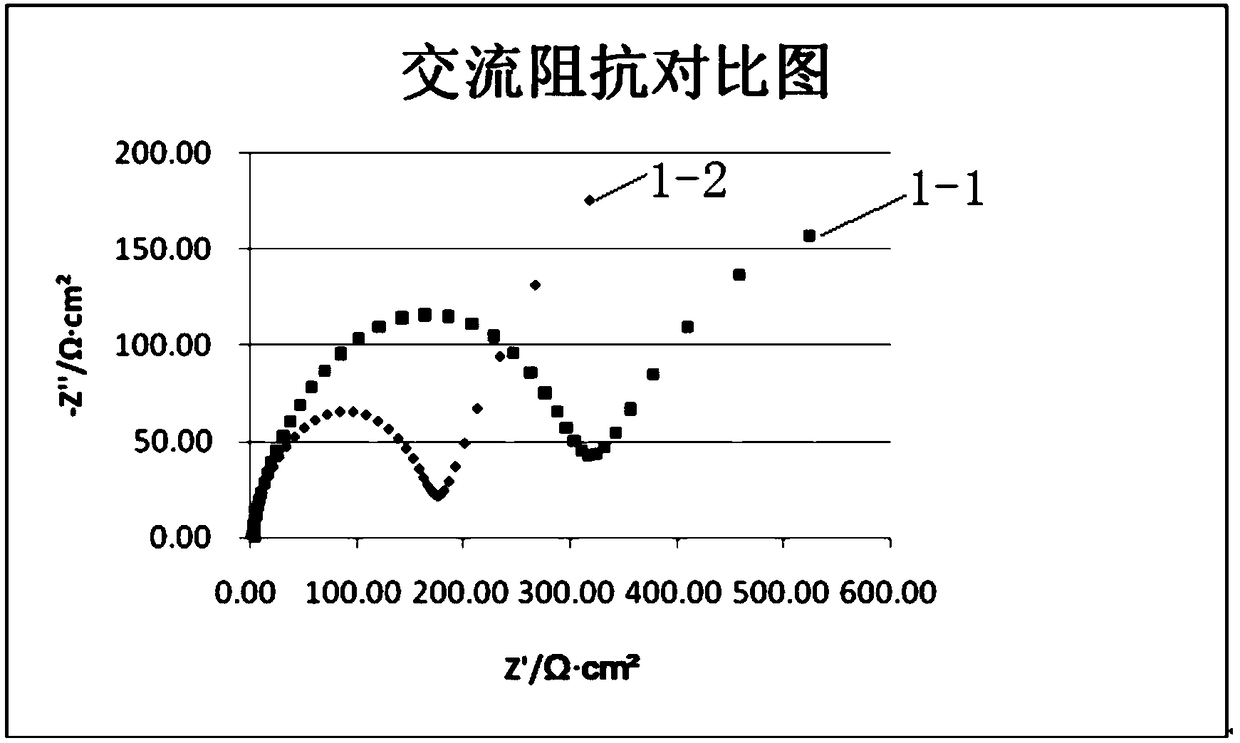

Embodiment 1

[0025] Select spherical graphite with D50 of 1um and D90 / D10=0.8, place it in a beaker, manually stir for 1min, ultrasonically disperse for 10min, and let it stand for later use. Nickel sulfate, cobalt sulfate and manganese sulfate are made into mixed solution according to Ni:Co:Mn molar ratio is 6:2:2 mixes, and the total number of moles of Ni, Co, Mn three kinds of transition metal ions is 2mol / L, then The NaOH solution of 4mol / L and the transition metal ion solution and the ammoniacal liquor of 4mol / L are added in the intermittent reaction container simultaneously, the feeding rate of control NaOH solution and transition ion solution is respectively 300ml / h and 100ml / h, and the control per unit The power obtained by the volume is 0.3kW / m 3 , the pH value of the reaction system was controlled to be 11.5, and the reaction temperature was 60°C. Then the obtained precipitate was filtered, washed, and dried at 120°C for 12 hours to obtain a precursor with a D50 of 4um and a cor...

Embodiment 2

[0027] Select D50 to be 8um, D90 / D10=0.62 mesophase carbon microspheres, place in a beaker, manually stir for 1min, ultrasonically disperse for 10min, and stand for later use. Nickel sulfate, cobalt sulfate and manganese sulfate are made into a mixed solution according to the Ni:Co:Mn molar ratio of 5:2:3, and the total moles of Ni, Co, and Mn three kinds of transition metal ions are 2.1mol / L, Then the ammoniacal liquor of the NaOH solution of 4mol / L and transition metal ion solution and 4mol / L is joined in the intermittent reaction vessel simultaneously, the feeding rate of control NaOH solution and transition ion solution is respectively 300ml / h and 100ml / h, controls every The power obtained per unit volume is 6kW / m 3 , the pH value of the reaction system was controlled to be 11.2, and the reaction temperature was 65°C. Then filter and wash the obtained precipitate, and dry at 120°C for 12 hours to obtain a D50 precursor with a core-shell structure of 12um, and combine the ...

Embodiment 3

[0029]Select D50 to be 5um, D90 / D10=0.59 carbon balls, place in a beaker, stir manually for 1min, ultrasonically disperse for 10min, and let stand for later use. Nickel sulfate, cobalt sulfate and manganese sulfate are made into a mixed solution according to the Ni:Co:Mn molar ratio of 8:1:1, and the total moles of Ni, Co, and Mn transition metal ions are 2.1mol / L. Then the ammoniacal liquor of the NaOH solution of 4mol / L and transition metal ion solution and 3.6mol / L is joined in the intermittent reaction vessel simultaneously, the feeding rate of control NaOH solution and transition ion solution is respectively 200ml / h and 80ml / h, controls The pH value of the reaction system was 11.7, and the reaction temperature was 65°C. Then the obtained precipitate is filtered, washed, and dried at 120°C for 12 hours to obtain a D50 precursor with a core-shell structure of 12um. The obtained core-shell precursor and lithium carbonate are mixed according to the ratio of M:Li=1:1.08 Propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com