Preparation method of manganese dioxide/carbon nanotube complex fuel cell cathode oxygen reduction catalyst

A fuel cell cathode and carbon nanotube technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve problems such as hindering the commercialization process of fuel cells, affecting battery output performance, and expensive Pt, etc., to achieve large-scale preparation Production, low cost of raw material sources, and the effect of more active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

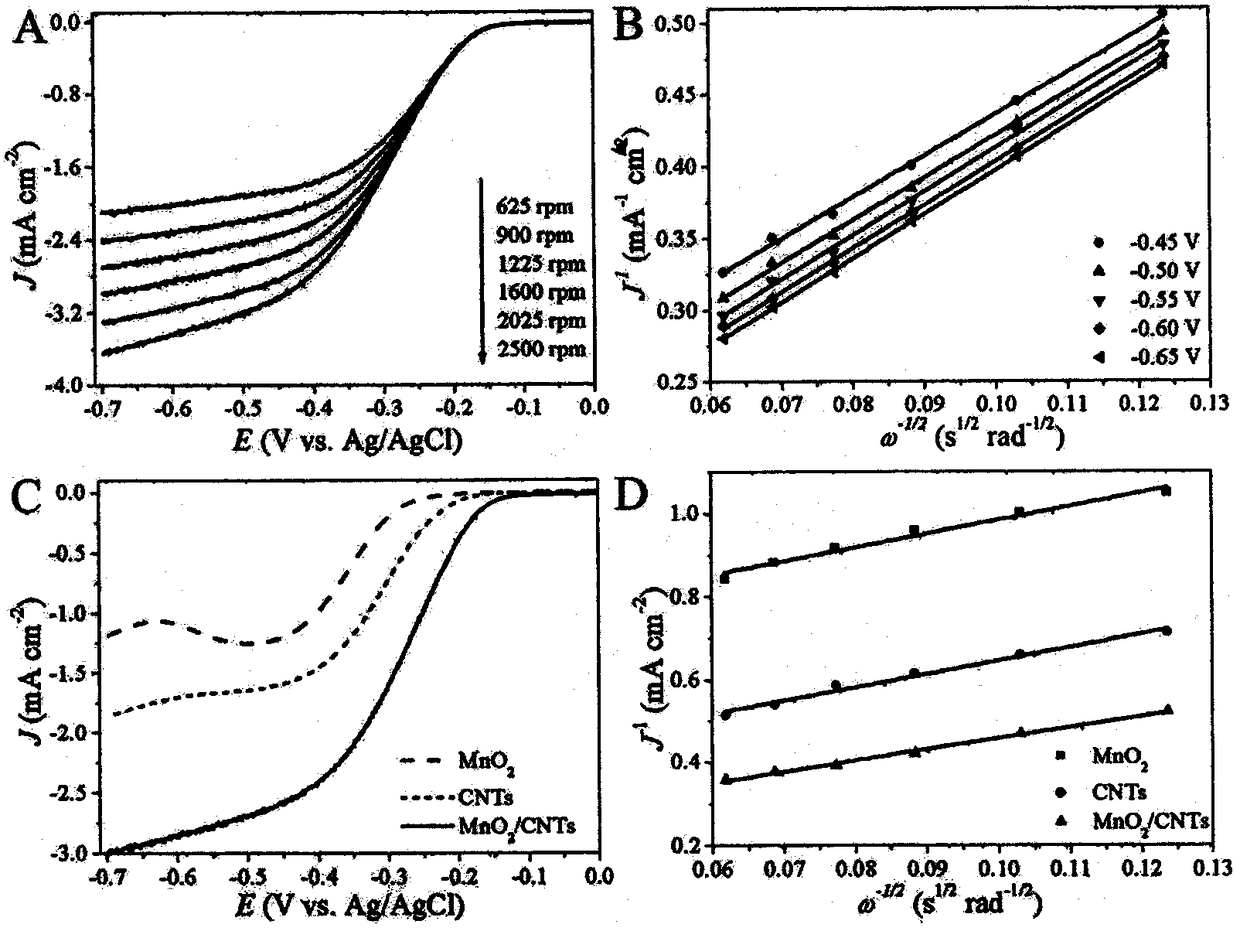

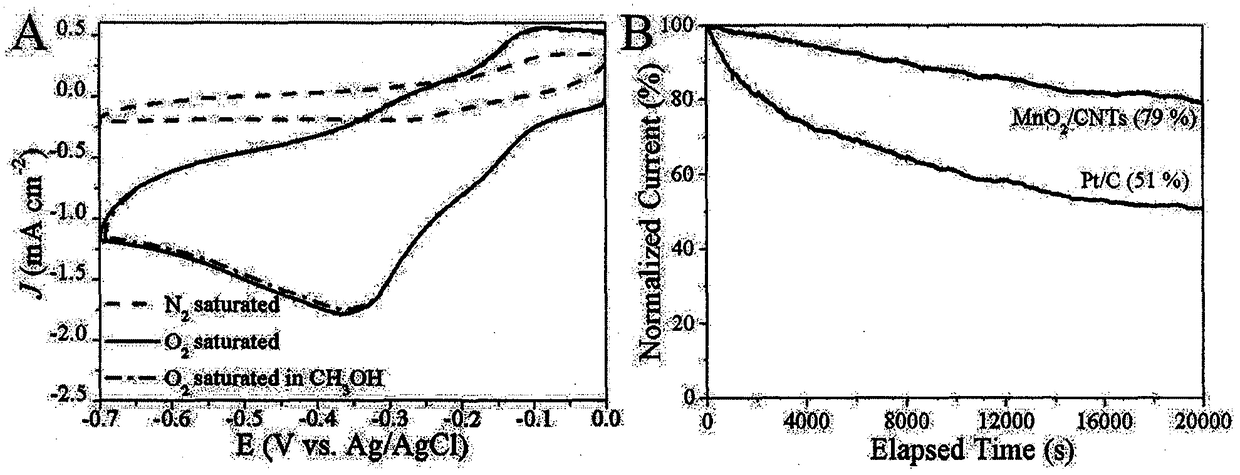

[0016] The invention provides a method for preparing a manganese dioxide / carbon nanotube composite fuel cell cathode oxygen reduction catalyst. The invention will be further described below in conjunction with the accompanying drawings and examples. Concrete preparation steps include:

[0017] (1) Preparation of activated carbon nanotubes: 1g of initial carbon nanotubes were dispersed in 50mL of concentrated nitric acid (68% by mass fraction), refluxed in an oil bath at 110°C for 6 hours, then filtered with a 0.2 micron filter membrane, washed with water until pH=7, the obtained powder is dried at 110°C for 12 hours to obtain activated carbon nanotubes.

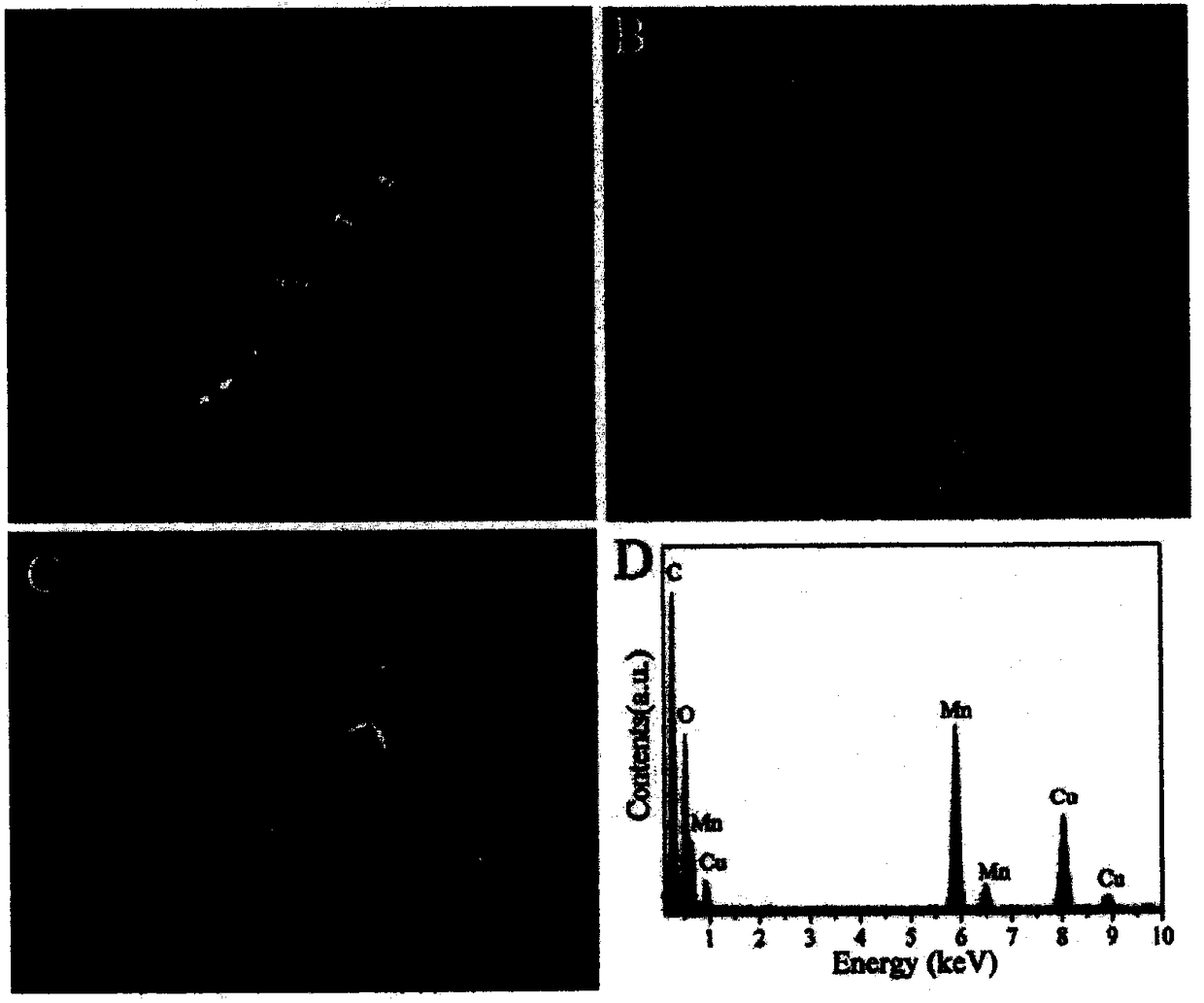

[0018] (2) Preparation of manganese dioxide / carbon nanotube composite: Activated carbon nanotubes of different masses and 25mL 0.05MKMnO 4 The solution was mixed evenly, then transferred to a 40mL autoclave, and reacted at 150°C for 16 hours. After it was naturally cooled to room temperature, it was washed with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com