PMMA/LLZN nanofiber composite solid electrolyte membrane as well as preparation and application thereof

A technology of solid electrolytes and nanofibers, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of low conductivity of PMMA-based solid electrolytes and low conductivity of solid electrolytes, and achieve increased electrochemical stability and thermodynamic stability properties, excellent ionic conductivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

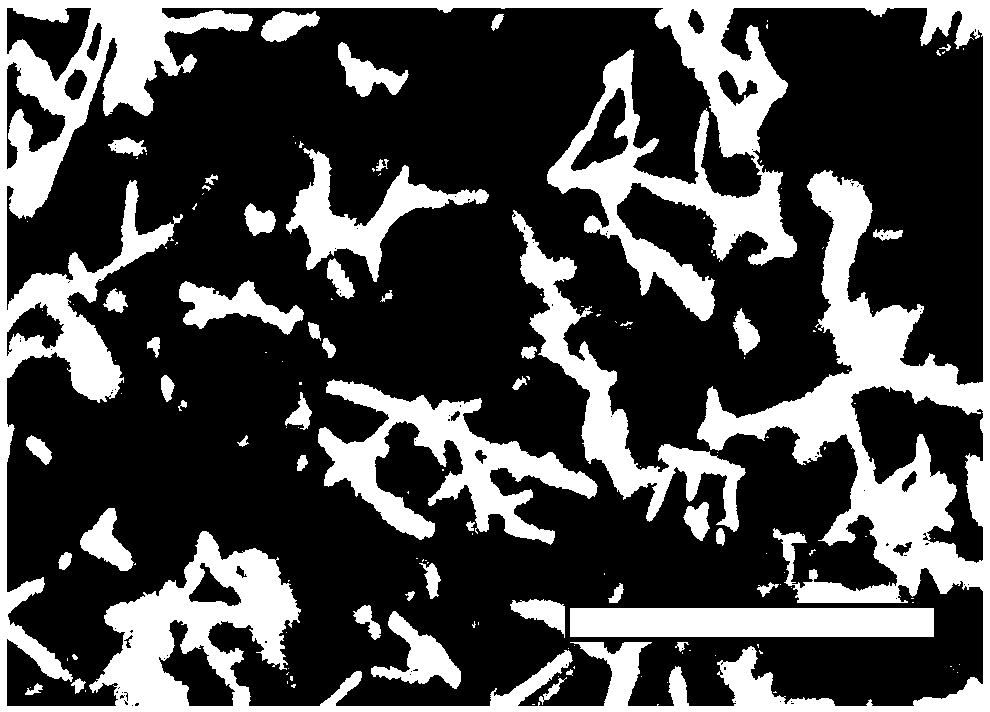

Image

Examples

Embodiment 1

[0038] (1) Weigh respectively 2.56g of vacuum-dried lithium nitrate, 6.50g of vacuum-dried lanthanum nitrate hexahydrate, 3.36g of zirconium n-butoxide and 0.338g of niobium pentachloride according to a certain molar ratio, and place them in a 250mL volumetric flask middle. Weigh 200mL of N,N-dimethylformamide and 50mL of acetic acid in a beaker respectively, add the mixed solution of the two into the volumetric flask, set to volume, and stir magnetically until the solute is completely dissolved. Weigh 20 g of the above-dissolved solution and 3 g of PVP into a 100 mL beaker, and stir magnetically until the PVP is completely dissolved. During the electrospinning process, the voltage was 20kV, the distance from the needle to the receiving plate was 10cm, the advancing speed was 1mL / h, and the spinning time was 20h to obtain the LLZN nanofiber precursor. The LLZN nanofiber precursor was calcined in a muffle furnace at a temperature of 900 °C, a heating rate of 2 °C / min, and a ca...

Embodiment 2

[0047] (1) Weigh respectively 2.68g of vacuum-dried lithium nitrate, 6.50g of vacuum-dried lanthanum nitrate hexahydrate, 3.36g of zirconium n-butoxide and 0.338g of niobium pentachloride according to a certain molar ratio, and place them in a 250mL volumetric flask middle. Weigh 200mL of N,N-dimethylformamide and 50mL of acetic acid in a beaker respectively, add the mixed solution of the two into the volumetric flask, set to volume, and stir magnetically until the solute is completely dissolved. Weigh 20 g of the above-dissolved solution and 2.6 g of PVP into a 100 mL beaker, and stir magnetically until the PVP is completely dissolved. During the electrospinning process, the voltage was 18kV, the distance from the needle to the receiving plate was 12cm, the advancing speed was 0.8mL / h, and the spinning time was 12h to obtain the LLZN nanofiber precursor. The LLZN nanofiber precursor was calcined in a muffle furnace at a temperature of 900 °C, a heating rate of 3 °C / min, and ...

Embodiment 3

[0051] (1) Weigh 2.80 g of vacuum-dried lithium nitrate, 6.50 g of vacuum-dried lanthanum nitrate hexahydrate, 3.36 g of zirconium n-butoxide and 0.338 g of niobium pentachloride according to a certain molar ratio, and place them in a 250 mL volumetric flask middle. Weigh 200mL of N,N-dimethylformamide and 50mL of acetic acid in a beaker respectively, add the mixed solution of the two into the volumetric flask, set to volume, and stir magnetically until the solute is completely dissolved. Weigh 20 g of the above-dissolved solution and 2.4 g of PVP into a 100 mL beaker, and stir magnetically until the PVP is completely dissolved. During the electrospinning process, the voltage was 18kV, the distance from the needle to the receiving plate was 15cm, the advancing speed was 0.5mL / h, and the spinning time was 36h to obtain the LLZN nanofiber precursor. The LLZN nanofiber precursor was calcined in a muffle furnace at a temperature of 800 °C, a heating rate of 5 °C / min, and a calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com