Porous heating element, atomizer with porous heating element and porous element preparation method

A porous body and system technology, applied in the field of electronic cigarettes, to achieve the effect of improving oil conductivity, quick liquid conduction, and improving replenishment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0120] Based on the above structure, and based on the idea of improving the overall porosity and smoke output, the present invention further proposes a porous body with higher e-liquid conduction and smoke output efficiency. The preparation method includes the following steps:

[0121] S10, obtain raw materials according to the following components of each mass percentage: 50% to 75% of diatomite, 0% to 10% of alumina, 15% to 35% of pore forming agent, 5% to 10% of clay, and 5% to glass powder 15%;

[0122] S20, mixing the above raw materials with paraffin evenly to make a raw wax block;

[0123] S30, pressing and molding the raw material wax block obtained in step S20 according to the final desired product shape to obtain a green embryo;

[0124] S40, heat the green embryo at 200-500° C. for 4-10 hours, and then sinter at 700-1200° C. for 2-4 hours to obtain a porous body.

[0125] In the above preparation process of the present invention, in step S10, the components sele...

Embodiment 1

[0135] S10, obtaining the following raw material components in various mass percentages: 70g of diatomite, 3g of alumina, 15g of wood fiber pore-forming agent, 5g of clay, and 7g of high-temperature glass powder;

[0136] S11, pour each raw material in step S10 into a planetary ball mill for wet ball milling for 5 hours, and the ball milling medium is deionized water to obtain a uniform mixed powder;

[0137]S20, melting an appropriate amount of paraffin into a liquid state at 80°C, pouring the mixed powder in step S11, cooling while stirring, so that the mixed powder is evenly wrapped with paraffin, and made into a raw material wax cake;

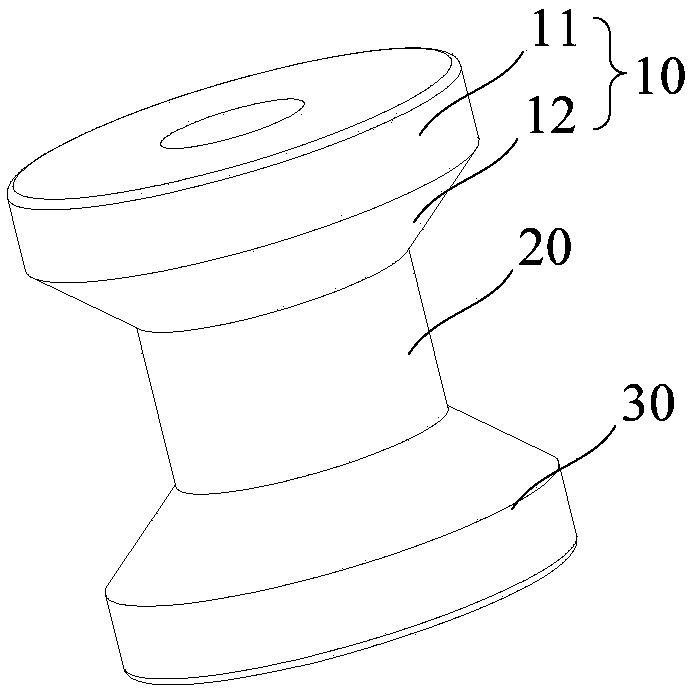

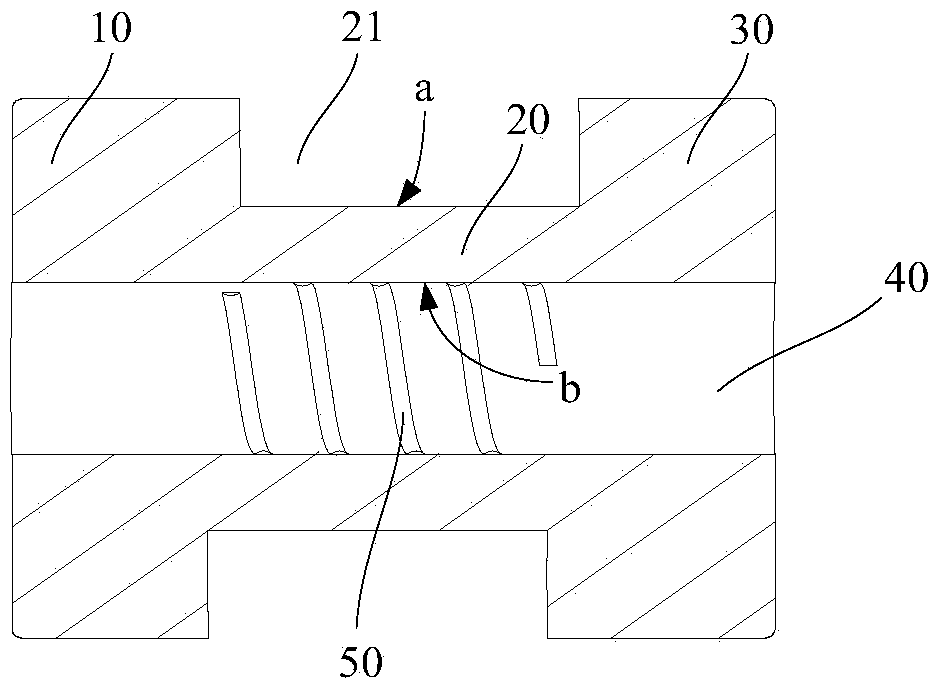

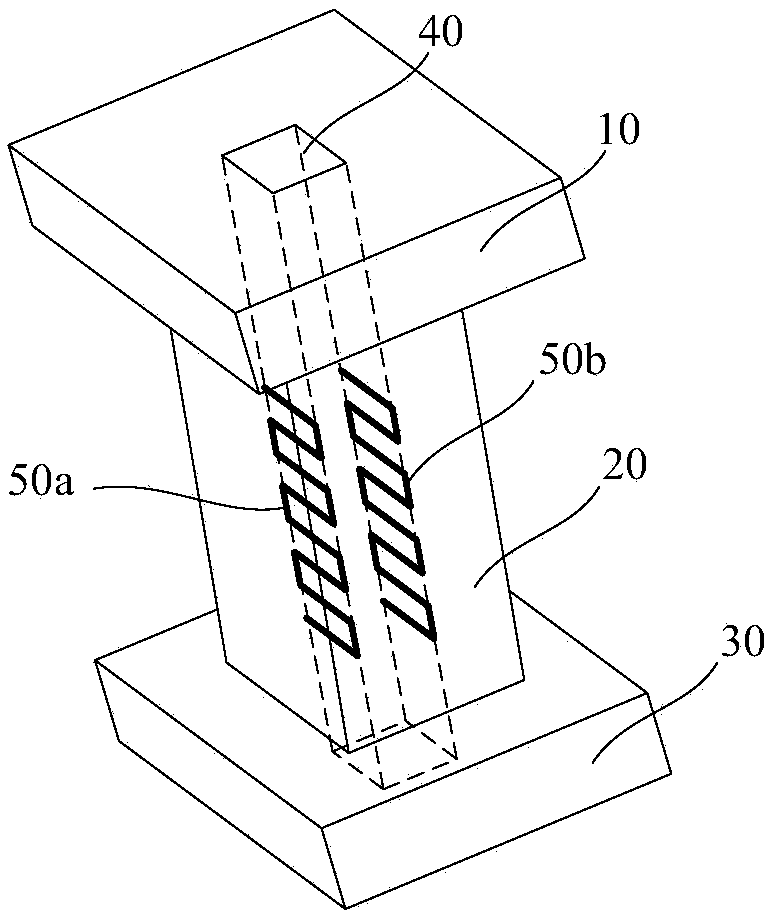

[0138] S30, pour the raw wax cake into the molding machine, control the temperature at 70°C and the pressure at 0.4MPa, and inject the wax cake slurry into the figure 1 In the mold of the corresponding shape of the porous body of the embodiment, a molded green body is obtained;

[0139] S40, the shaped green body is firstly kept at 200° C....

Embodiment 2

[0141] S10, obtaining the following raw material components in various mass percentages: 65g of diatomite, 25g of sucrose pore-forming agent, 5g of clay, and 5g of high-temperature glass powder;

[0142] S11, pour the raw materials in step S10 into a planetary ball mill for wet ball milling for 4 hours, and the ball milling medium is absolute ethanol to obtain a uniform mixed powder;

[0143] S20, melting an appropriate amount of paraffin into a liquid state at 80°C, pouring the mixed powder in step S11, cooling while stirring, so that the mixed powder is evenly wrapped with paraffin, and made into a raw material wax cake;

[0144] S30, pour the raw wax cake into the molding machine, control the temperature at 85°C and the pressure at 1MPa, and inject the wax cake slurry into the figure 1 In the mold of the corresponding shape of the porous body of the embodiment, a molded green body is obtained;

[0145] S40, the molded green body is first kept at 500° C. for 4 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com