Preparation method for synthesizing polymetallic carbides from carbon nanotubes

A technology of carbon nanotubes and multi-metals, which is applied in the field of synthesis of multi-metal carbides, can solve the problems of non-universality and achieve the effect of simple equipment requirements and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

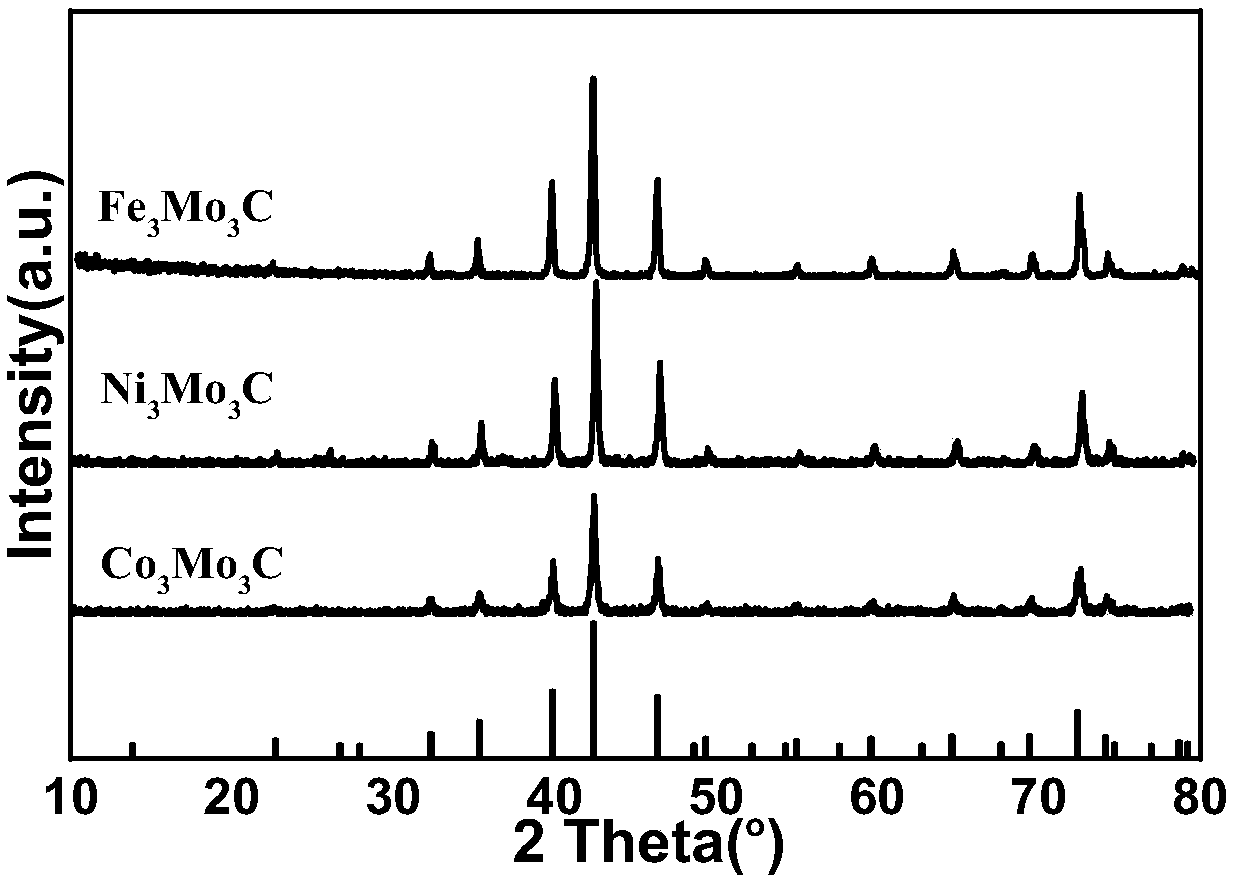

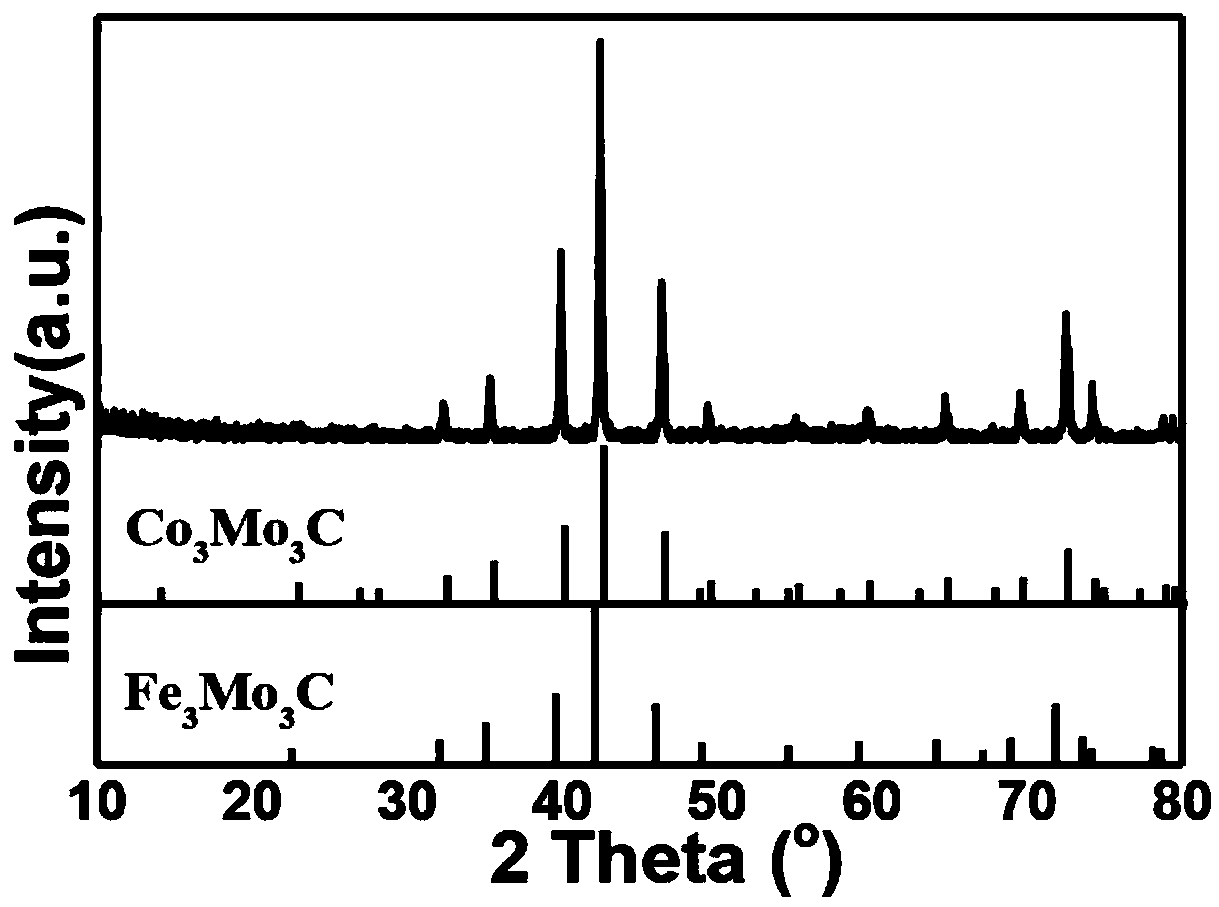

Embodiment 1

[0021] Mix 38mg ammonium molybdate, 62mg cobalt nitrate and 13mg carbon nanotubes evenly, put the resulting mixture into a quartz tube, inert atmosphere N 2 Under protection, the mixture was raised from room temperature to 950°C (heating rate: 3°C / min), calcined for 3 hours, and cooled to room temperature. The resulting gray powder is the cobalt-molybdenum bimetallic carbide Co 3 Mo 3 c. The material was tested for electrocatalytic hydrogen evolution performance under the condition of 1M KOH, reaching 10mA cm -2 , an overpotential of 169mV is required.

Embodiment 2

[0023] Mix 38mg of ammonium molybdate, 62mg of nickel nitrate and 13mg of carbon nanotubes evenly, put the resulting mixture into a quartz tube, inert atmosphere N 2 Under protection, the mixture was raised from room temperature to 950°C (heating rate: 3°C / min), calcined for 3 hours, and cooled to room temperature. The obtained gray powder is nickel-molybdenum bimetallic carbide Ni 3 Mo 3 c. The material was tested for electrocatalytic hydrogen evolution performance under the condition of 1M KOH, reaching 10mA cm -2 , an overpotential of 217mV is required.

Embodiment 3

[0025] Mix 31mg ammonium molybdate, 69mg ferric nitrate and 13mg carbon nanotubes evenly, put the resulting mixture into a quartz tube, inert atmosphere N 2 Under protection, the mixture was raised from room temperature to 950°C (heating rate: 3°C / min), calcined for 3 hours, and cooled to room temperature. The obtained gray powder is iron-molybdenum bimetallic carbide Fe 3 Mo 3 c. The material was tested for electrocatalytic hydrogen evolution performance under the condition of 1M KOH, reaching 10mA cm -2 , an overpotential of 302mV is required.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap