Graphene/graphite-like-phase carbon nitride/palladium nano particle multistage nano-structure composite material preparation method and application

A technology of graphite phase carbon nitride and nanostructure, which is applied in the direction of chemical instruments and methods, structural parts, physical/chemical process catalysts, etc., can solve the problems of low methanol oxidation catalytic activity and small specific surface area, and reduce the ratio of graphene The effect of surface reduction, simple process and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

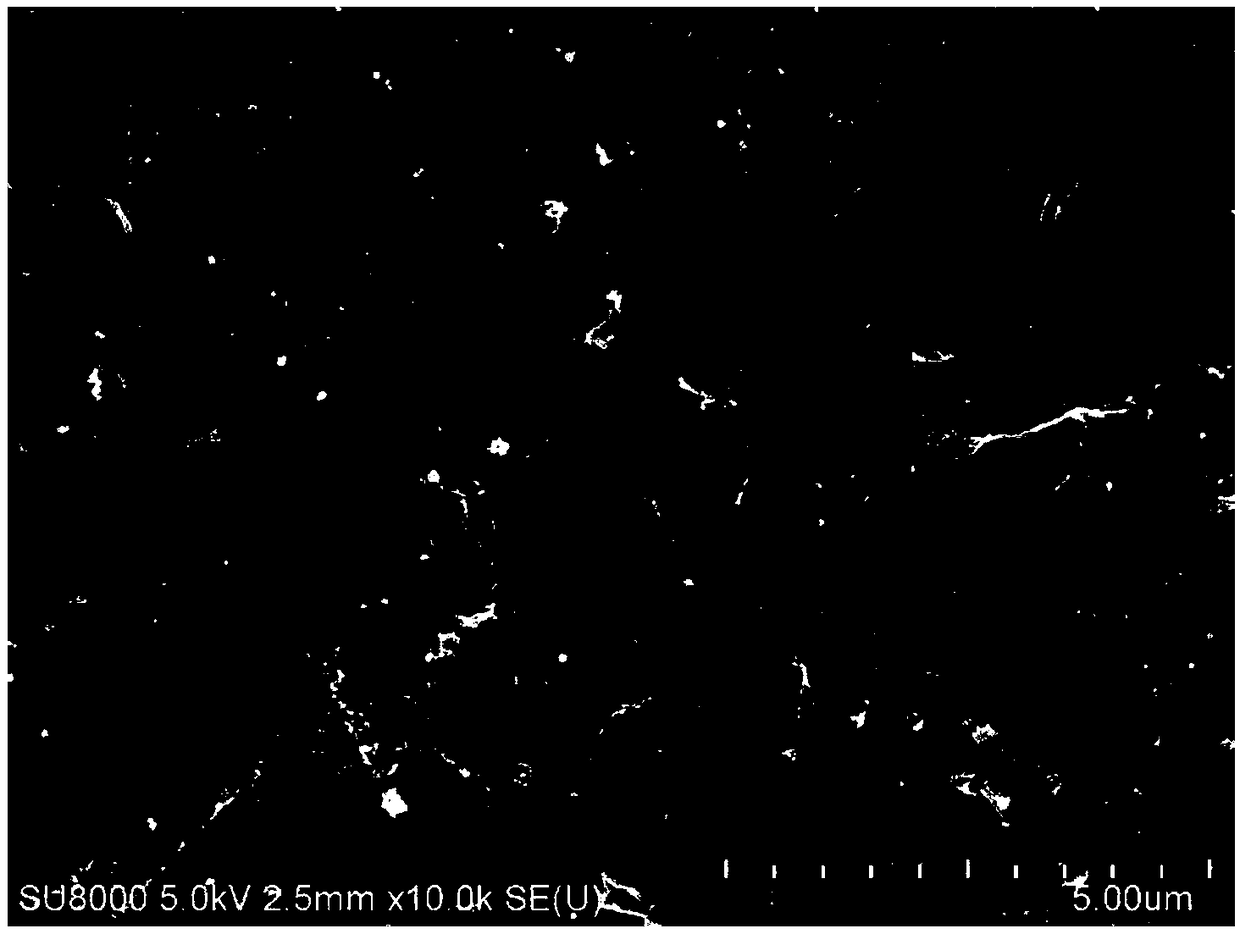

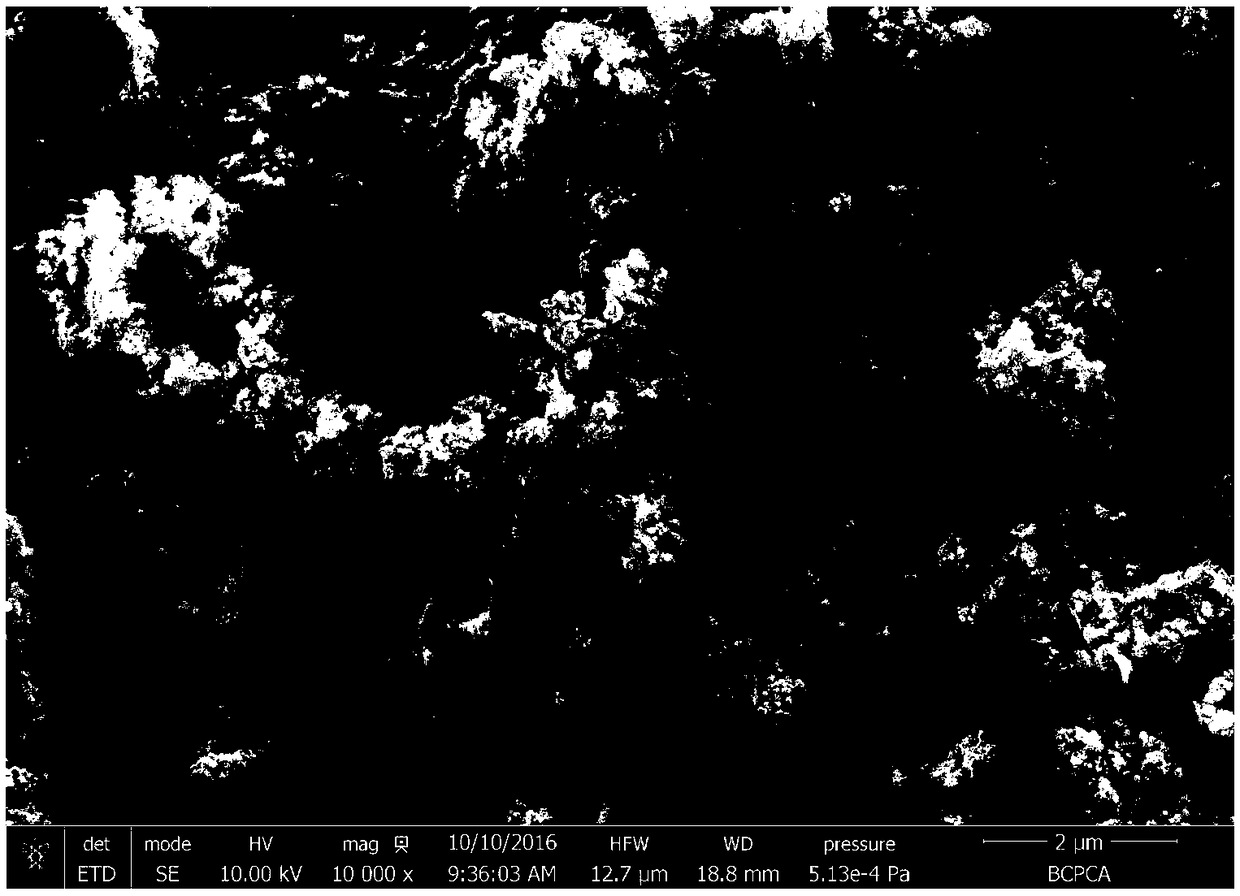

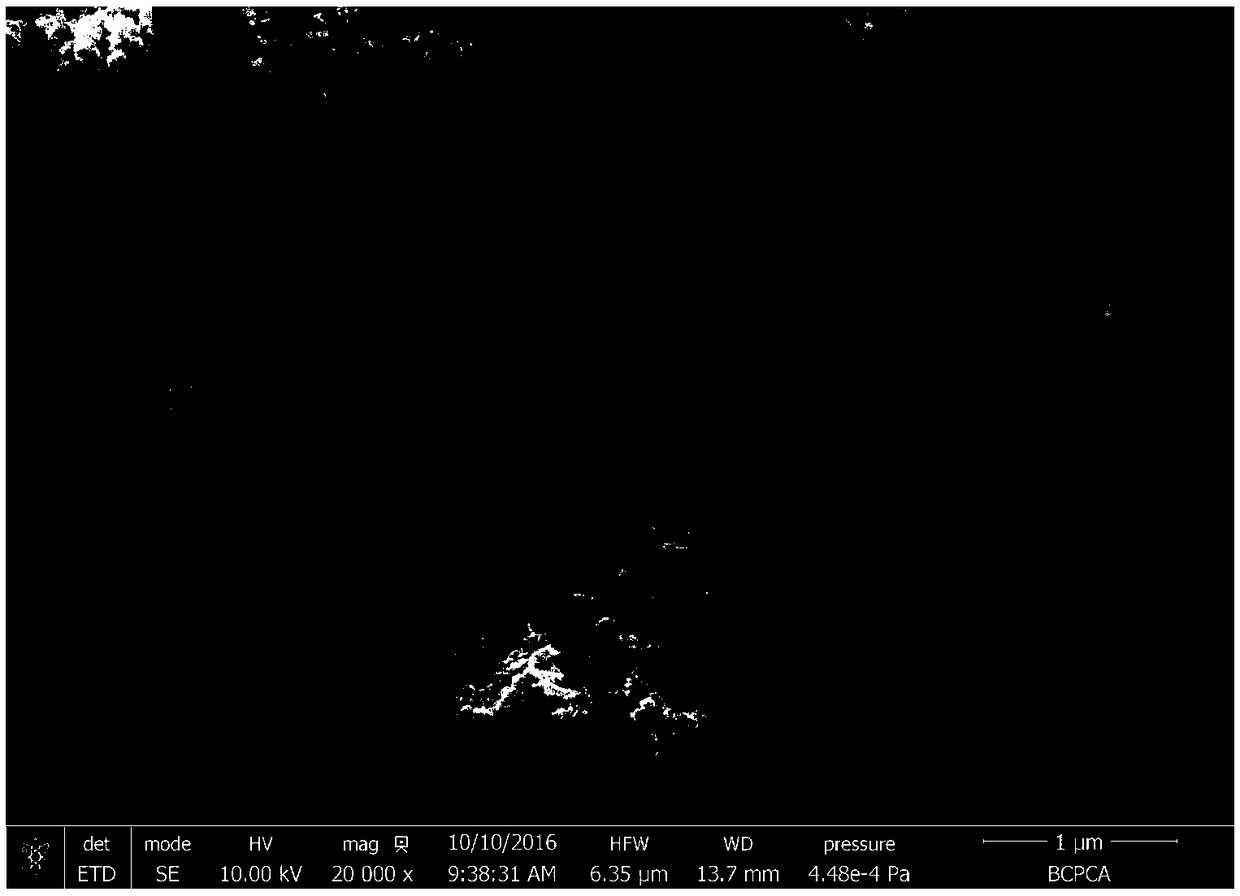

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: this embodiment is a kind of preparation method of graphene / graphite-like phase carbon nitride / palladium nanoparticle multilevel nanostructure composite material, specifically carries out according to the following steps:

[0023] 1. Ultrasonic disperse graphite oxide in a citric acid-sodium citrate buffer solution with a pH of 6.0 for 3h to 3.5h to obtain a graphene oxide solution with a concentration of 0.2g / L to 0.25g / L;

[0024] PdCl 2 Mix with NaCl evenly, then add secondary water, stir magnetically at room temperature for 10h~11h, and get Na with a concentration of 0.1mol / L~0.12mol / L 2 PdCl 4 solution; the NaCl and PdCl 2 The mass ratio of 0.65:1;

[0025] Put the melamine into the horse boiling furnace, raise the temperature from room temperature to 550°C-600°C under the condition of heating rate of 2.3°C / min-2.5°C / min, keep the temperature at 550°C-600°C for 3h-5h, and then Drop to room temperature at a cooling rate of 1°C / min to obt...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the graphite oxide described in step 1 is obtained by the Improved oxidation method. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: g-C described in step two 3 N 4 The volume ratio of dispersion liquid to graphene oxide solution is 1:10. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com