Repairing method of gray pig iron heterogeneous welding line

A repair method and technology for gray cast iron, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of gray cast iron castings that are not easy to repair, insufficient weld strength, and low weld plasticity. Welding stress, effect of good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

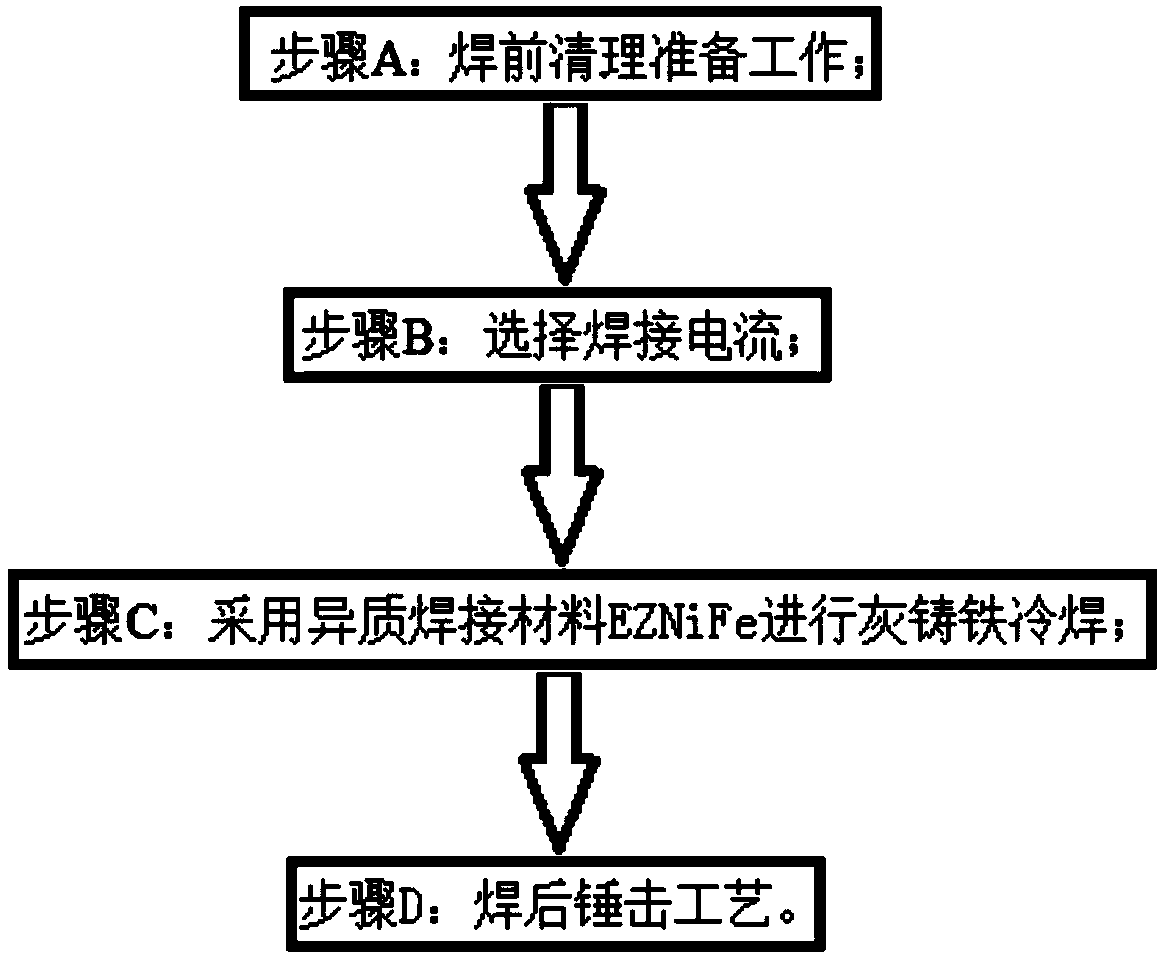

[0047] Such as figure 1 Shown is a flow chart of a method for repairing a gray cast iron heterogeneous weld according to the present invention. In the method for repairing a gray cast iron heterogeneous weld in this embodiment, the repair steps are as follows:

[0048] Step A: Cleaning and preparation work before welding;

[0049] Step A 1 : Remove debris on castings and defects;

[0050] Step A 2 : remove oil stains on castings and defects, the method for removing oil stains on castings and defects is scrubbing with alkaline water or gasoline scrubbing or removing with gas welding flames to avoid pore defects;

[0051] Step A 3 : Observing crack defects and performing preliminary treatment on crack defects;

[0052] Step A 31 : measure the length of the crack defect;

[0053] Step A 32 : Make the crack defect into a groove, which is beneficial to welding;

[0054] Step A 33 : Drill a crack stop hole 3mm away from the end of the crack, the diameter of the crack stop ho...

Embodiment 2

[0059] Such as figure 1 Shown is a flow chart of a method for repairing a gray cast iron heterogeneous weld according to the present invention. In the method for repairing a gray cast iron heterogeneous weld in this embodiment, the repair steps are as follows:

[0060] Step A: Cleaning and preparation work before welding;

[0061] Step A 1 : Remove debris on castings and defects;

[0062] Step A 2 : remove oil stains on castings and defects, the method for removing oil stains on castings and defects is scrubbing with alkaline water or gasoline scrubbing or removing with gas welding flames to avoid pore defects;

[0063] Step A 3 : Observing crack defects and performing preliminary treatment on crack defects;

[0064] Step A 31 : measure the length of the crack defect;

[0065] Step A 32 : Make the crack defect into a groove, which is beneficial to welding;

[0066] Step A 33 : Drill a crack stop hole 5mm away from the end of the crack, the diameter of the crack stop ...

Embodiment 3

[0071] Such as figure 1 Shown is a flow chart of a method for repairing a gray cast iron heterogeneous weld according to the present invention. In the method for repairing a gray cast iron heterogeneous weld in this embodiment, the repair steps are as follows:

[0072] Step A: Cleaning and preparation work before welding;

[0073] Step A 1 : Remove debris on castings and defects;

[0074] Step A 2 : remove oil stains on castings and defects, the method for removing oil stains on castings and defects is scrubbing with alkaline water or gasoline scrubbing or removing with gas welding flames to avoid pore defects;

[0075] Step A 3 : Observing crack defects and performing preliminary treatment on crack defects;

[0076] Step A 31 : measure the length of the crack defect;

[0077] Step A 32 : Make the crack defect into a groove, which is beneficial to welding;

[0078] Step A 33 : Drill a crack stop hole 4mm away from the end of the crack, the diameter of the crack stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com