Method for preparing magnesium oxide crystal whiskers from brine through hydrothermal-basic magnesium chloride precursor

The technology of magnesium oxide whisker and magnesium chloride is applied in the field of marine chemical industry, and can solve the problems of poor quality of magnesium oxide whisker, difficulty in realizing industrialization, complicated process, etc., and achieve the effects of good appearance, low production cost and simple process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

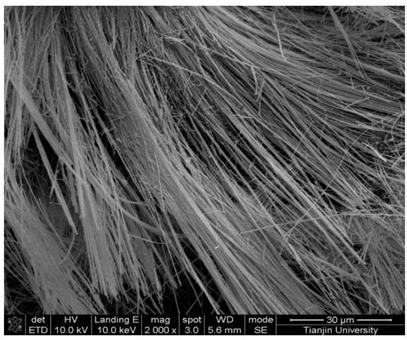

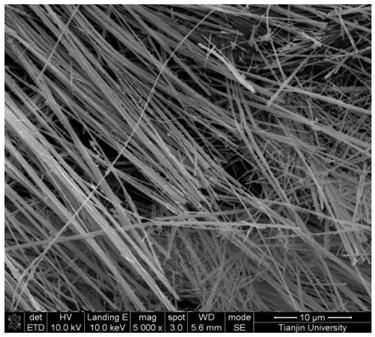

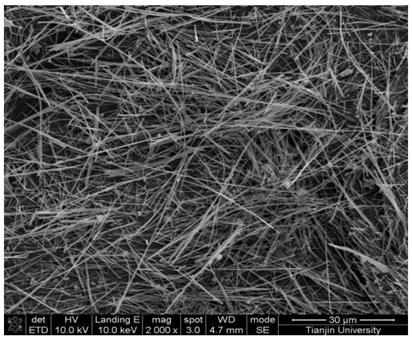

Image

Examples

Embodiment 1

[0031] First, take 200ml of brine from the salt field, measure the concentration of magnesium ions in the brine of the salt field, add a certain volume of deionized water to dilute, and adjust the concentration of magnesium ions in the brine to 3mol / L. Configure 200ml of sodium hydroxide solution so that the molar ratio of magnesium ions to sodium hydroxide is 8.

[0032] Add the prepared brine to sodium hypochlorite for purification treatment, the volume ratio of sodium hypochlorite to brine is 1:1000, turn on the stirring device, the stirring speed is 150r / min, the stirring time is 15min, and then keep the settling time for 3.5h.

[0033] Put the purified brine into the crystallizer, turn on the stirring device, control the stirring rate at 150r / min, and add anhydrous ethanol with a volume fraction of 20% after the system is stable. Under the condition of keeping stirring, the sodium hydroxide solution prepared above was slowly added dropwise into the brine at a titration ra...

Embodiment 2

[0039] First, take 100ml of salt field brine, measure the concentration of magnesium ions in the salt field brine, add a certain volume of deionized water to dilute, and adjust the concentration of magnesium ions in the brine to 4mol / L. Configure 100ml of sodium hydroxide solution so that the molar ratio of magnesium ions to sodium hydroxide is 8.

[0040] Add the prepared brine to sodium hypochlorite for purification treatment, the volume ratio of sodium hypochlorite to brine is 1:1000, turn on the stirring device, the stirring speed is 100r / min, the stirring time is 10min, and then keep the settling time for 3h.

[0041] Put the purified brine into the crystallizer, turn on the stirring device, control the stirring rate at 100r / min, and add anhydrous ethanol with a volume fraction of 15% after the system is stable. Under the condition of keeping stirring, the sodium hydroxide solution configured above was slowly added dropwise into the brine at a titration rate of 10 d / min, ...

Embodiment 3

[0047] First, take 200ml of brine from the salt field, measure the concentration of magnesium ions in the brine of the salt field, add a certain volume of deionized water to dilute, and adjust the concentration of magnesium ions in the brine to 3mol / L. Configure 200ml of sodium hydroxide solution so that the molar ratio of magnesium ions to sodium hydroxide is 7.

[0048] Add the prepared brine to sodium hypochlorite for purification treatment, the volume ratio of sodium hypochlorite to brine is 1:1000, turn on the stirring device, the stirring speed is 150r / min, the stirring time is 15min, and then keep the settling time for 3.5h.

[0049] Put the purified brine into the crystallizer, turn on the stirring device, control the stirring rate at 150r / min, and add anhydrous ethanol with a volume fraction of 20% after the system is stable. Under the condition of keeping stirring, the sodium hydroxide solution configured above was slowly added dropwise into the brine at a titration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com