Polymeric fiber and preparation method thereof

A polymer and fiber technology, applied in the field of composite ultra-high molecular weight polyethylene fiber and its preparation, can solve the problems of poor dispersion of inorganic fillers and high viscoelasticity, and achieve good spinnability, long-term stability, and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

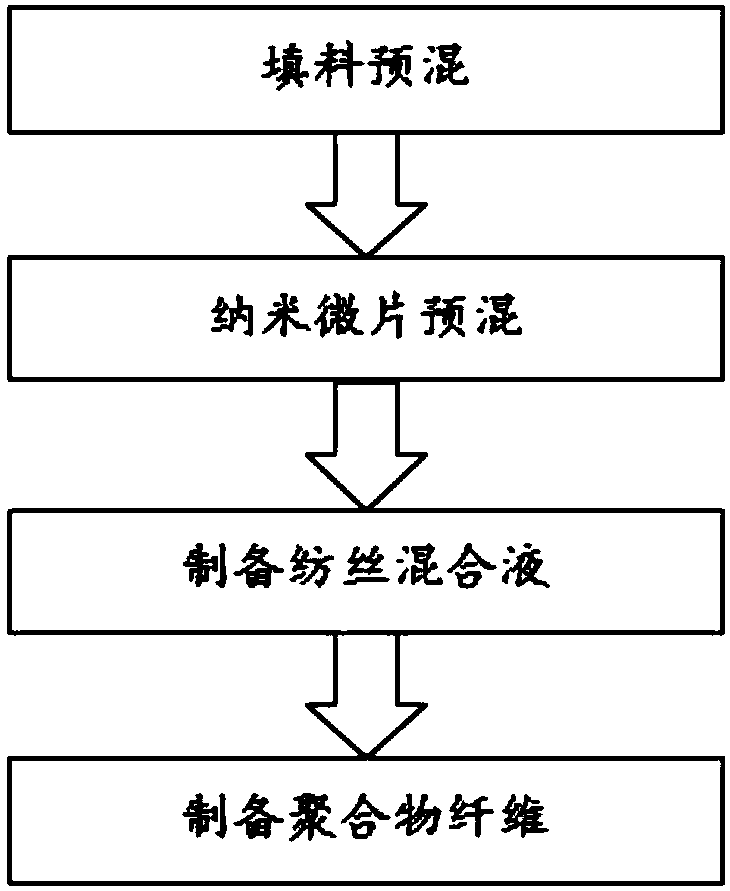

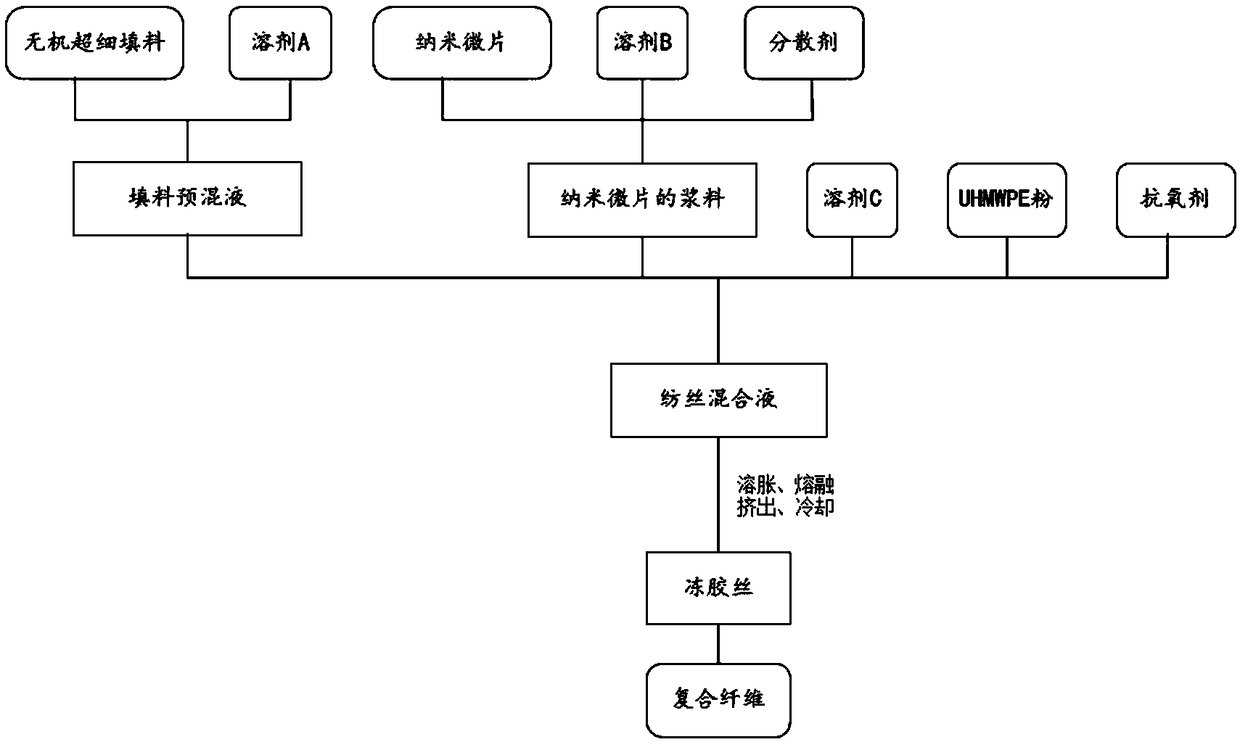

[0075] In one embodiment of the present invention, refer to figure 1 , figure 2 , Provides a method for preparing polymer fibers, using the components and contents of the above-mentioned polymer fibers, including:

[0076] Filler premix: Mix the inorganic ultrafine filler with solvent A and stir with an emulsifier to obtain a filler premix;

[0077] Pre-mixing of nano microchips: mix nano microchips with solvent B and dispersant, stir, enter the homogenizer, and discharge to form a slurry;

[0078] Preparation of the spinning mixture: swelling the filler premix, and mixing the slurry of the nanochips with solvent C, UHMWPE powder and antioxidant to obtain a spinning mixture;

[0079] Preparation of polymer fibers: swelling, melt-extrusion, and cooling the spinning mixture to obtain jelly threads, and polymer fibers are prepared from the jelly threads.

[0080] The solvent A, solvent B, and solvent C are all one or a combination of two or more of n-heptane, cyclohexane, paraffin oil, v...

Embodiment 1

[0110] 1) Preparation of fiber premix

[0111] Pour 2kg of basalt fiber into 98kg of paraffin oil to premix, and stir for 15min at 1000rpm with an emulsifier.

[0112] 2) Preparation of graphene slurry

[0113] Add 0.1kg of graphene and 0.02kg of dispersant AFCONA4700 to 99.88kg of paraffin oil (the graphene slurry concentration is 0.1%). After stirring for 10 minutes at a high-speed shearing machine at 500 rpm, enter the ultra-high pressure micro-jet homogenizer (pressure Set to 3000bar), grind twice to the particle size required by graphene (D99≤5um), and discharge.

[0114] 3) Preparation of spinning solution

[0115] Pour the solutions of steps 1) and 2) into a swelling kettle containing 1101.2 kg of paraffin oil under high-speed stirring, and then add 97.78 kg of UHMWPE powder and 0.1 kg of antioxidant 1010 (graphene accounts for 0.1% of the composite fiber, basalt The fiber accounts for 2% of the composite fiber, and the antioxidant accounts for 0.1% of the composite fiber), whi...

Embodiment 2

[0119] 1) Preparation of fiber premix

[0120] Pour 6kg of silica particles into 114kg of white oil for premixing, and stir for 10min with an emulsifier at 2000rpm.

[0121] 2) Preparation of graphene slurry

[0122] Add 0.5kg of graphene powder and 0.5kg of dispersant PSS to 49kg of white oil (the graphene slurry concentration is 1%). After stirring for 7 minutes at a high-speed shearing machine at 2000 rpm, enter the ultra-high pressure micro-jet homogenizer ( The pressure is set to 3200bar), cyclically grind twice to the particle size required by graphene (D99≤5um), and discharge.

[0123] 3) Preparation of spinning solution

[0124] Pour the solutions of steps 1) and 2) into a swelling kettle containing 1072.44kg of white oil under high-speed stirring, and then add 92.99kg UHMWPE powder and 0.01kg antioxidant DNP (graphene accounts for 0.5% of the composite fiber, The silica particles account for 6% of the composite fiber, and the antioxidant accounts for 0.01% of the composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com