CuCo bimetal organic framework composite sulfur material and preparation and application thereof

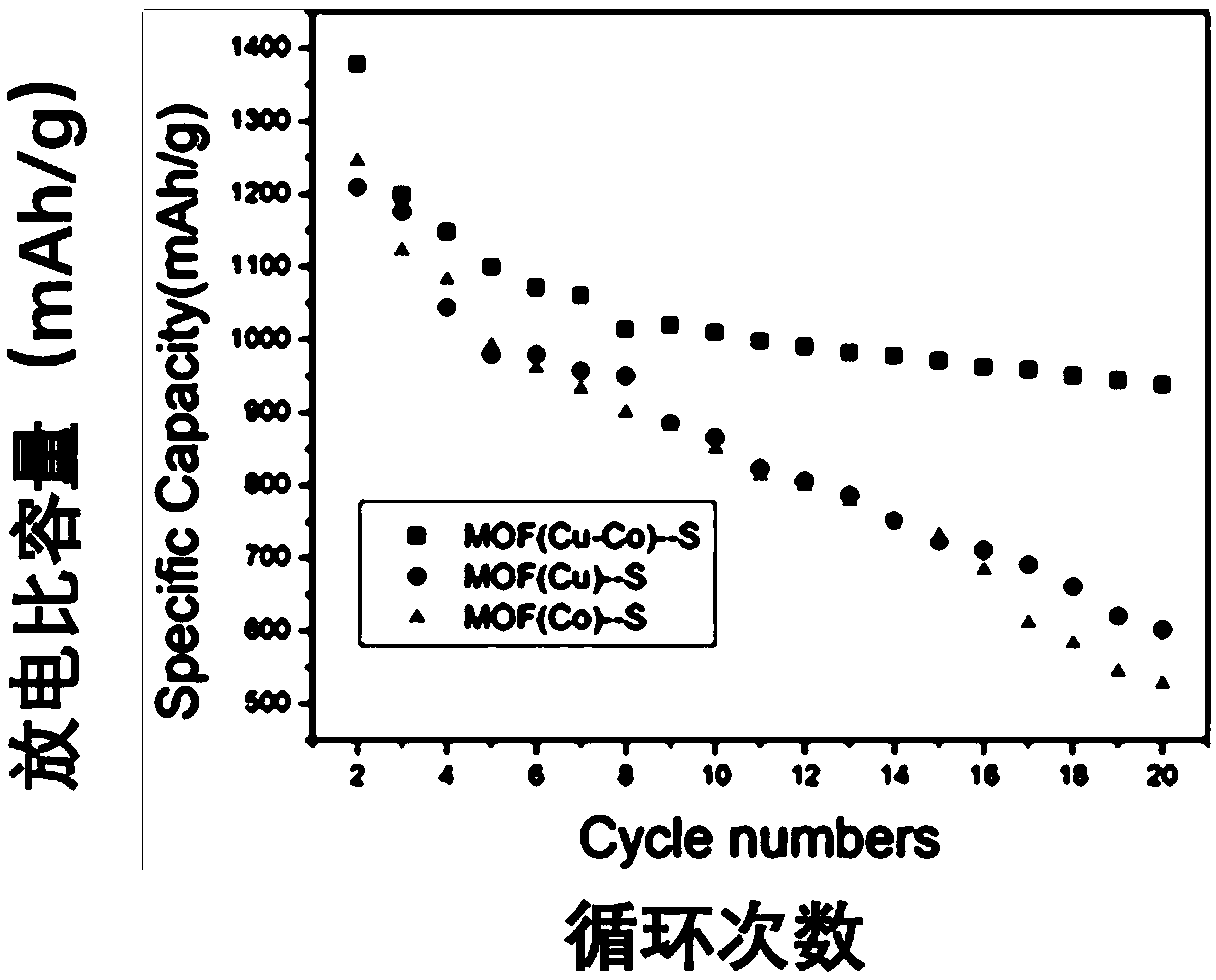

An organic framework, bimetallic technology, applied in the field of materials, can solve the problems of rapid capacity decay of lithium-sulfur batteries and unstable cathode material structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

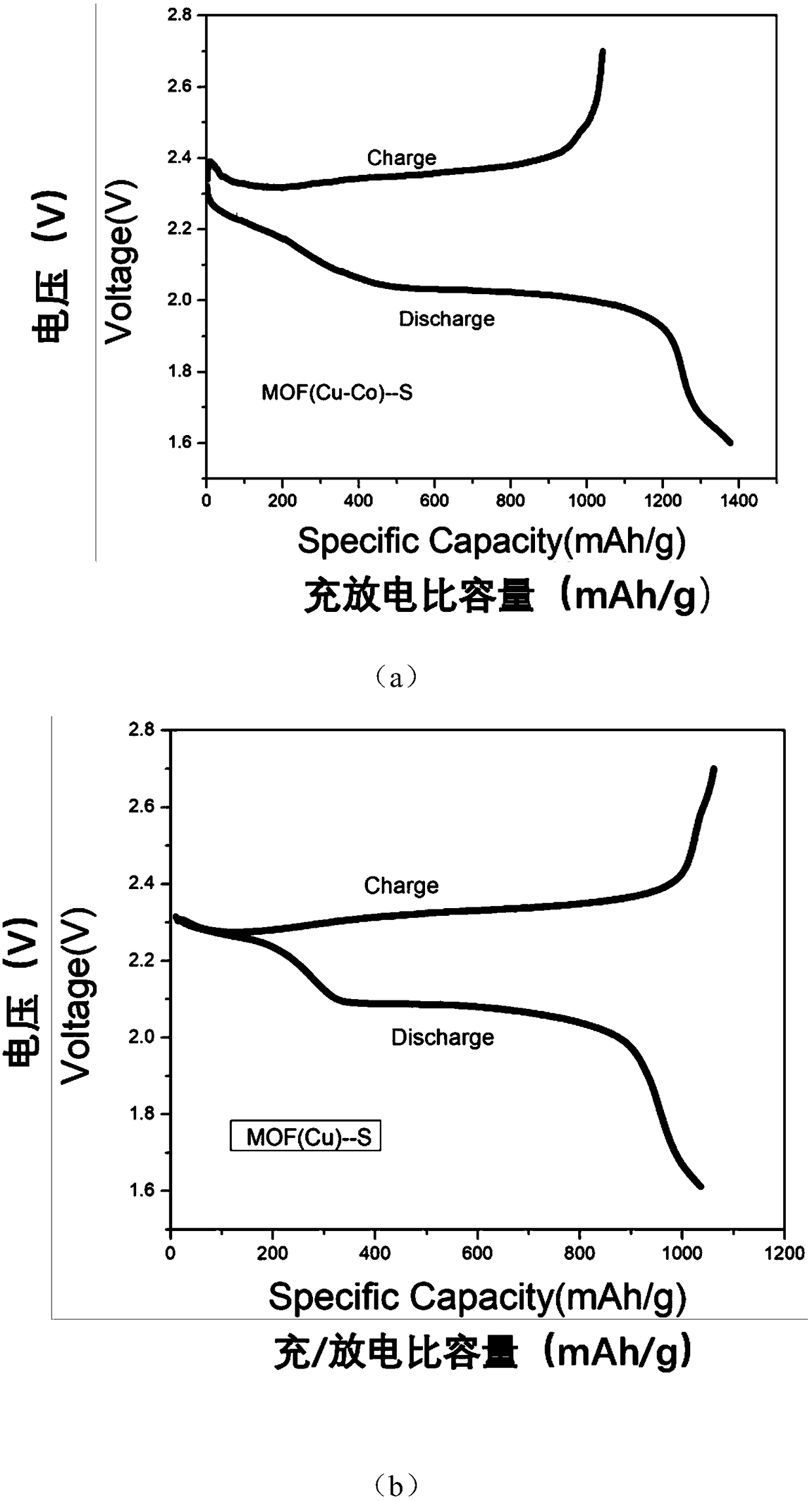

[0032] Step 1: Weigh 0.035g of Cu(NO 3 )3H 2 O, 0.02g H 3 NTB, 0.02 g of DABCO as metal salt and organic ligand, 1 mL of ethanol, 3 mL of DMA, 1 mL of DMSO, 0.1 mL of fluoroboric acid and 1 mL of 1,4-do were added to the above mixture, respectively. The obtained solution was magnetically stirred until the solution was uniformly mixed, and then put into a drying oven at 85° C. for 5-7 days to dry. The dark green crystal obtained after taking it out was the MOF crystal with Cu as the central metal atom.

[0033]Step 2: Grind and mix the obtained MOF crystals and elemental sulfur powder in a ratio of 2:3 in an argon-filled glove box. After being completely ground, put it into a tube furnace for sintering, the temperature is 155 degrees, and the holding time is 2 hours. Take it out after cooling to room temperature naturally. Obtain MOF-S complex.

[0034] Step 3: Put the MOF-S composite obtained in Step 2 into a tube furnace for carbonization. In a tube furnace filled with ...

Embodiment 2

[0036] Step 1: Weigh 0.036g of Co(NO 3 ) 2 6H 2 O was dissolved in 5mL of methanol solution, 0.047g of 2-methylimidazole was dissolved in 5mL of methanol solution, the two were mixed, stirred on a magnetic stirrer for 30min, and after standing for 24h, the resulting solution was washed and filtered to obtain purple Precipitate, and then put it in a dry box overnight at 70 degrees to obtain a MOF crystal with Co as the central atom.

[0037] Step 2: Grind and mix the obtained MOF crystals and elemental sulfur powder in a ratio of 2:3 in an argon-filled glove box. After being completely ground, put it into a tube furnace for sintering, the temperature is 155 degrees, the holding time is 2 hours, and then it is naturally cooled to room temperature and taken out. Obtain MOF-S complex.

[0038] Step 3: Put the MOF-S composite obtained in Step 2 into a tube furnace for carbonization. In a tube furnace filled with argon, the carbonization temperature was set at 600 °C, and the h...

Embodiment 3

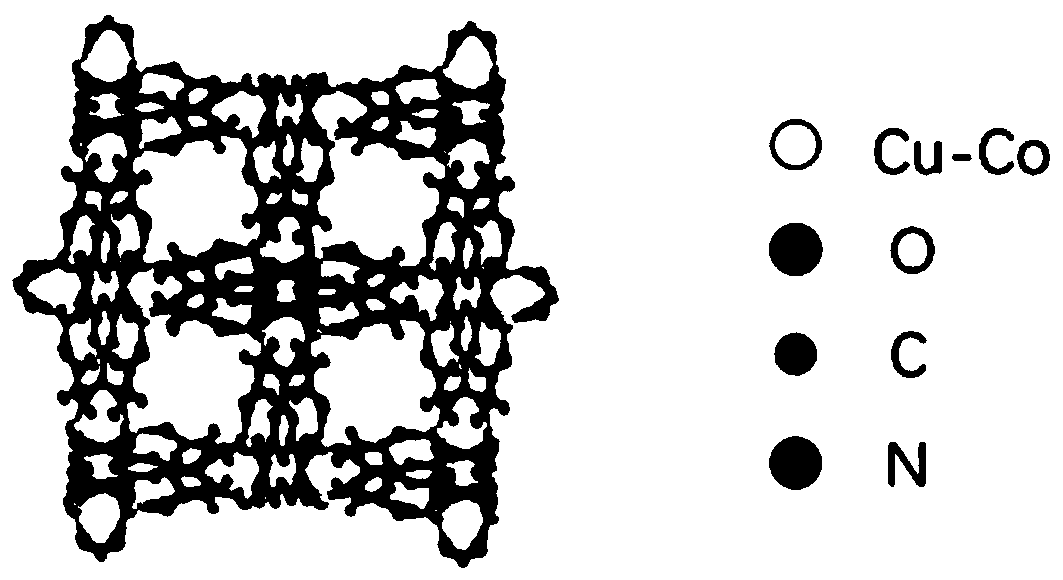

[0040] Step 1: Weigh 0.036gCu(NO 3 )3H 2 O and 0.036g Co(NO 3 ) 2 6H 2 O was added into a small glass bottle as a metal salt, and 0.02gH was weighed 3 NTB, 0.02 g DABCO, and 0.045 g 2-methylimidazole were used as organic ligands, and then 3 mL DMA, 1 mL DMSO, 1 mL ethanol, 0.1 mL fluoroboric acid, 1 mL 1, 4do, and 8 mL methanol were added dropwise to the above mixture. Put the above solution into a magnetic stirrer and stir until it is evenly mixed, and then put it into a drying oven to dry at 85° C. for 5-7 days. After extraction, the bimetallic MOF crystal structure was obtained.

[0041] Step 2: Grinding and mixing the bimetallic MOF crystal and elemental sulfur powder obtained above in a ratio of 2:3 in an argon-filled glove box. After being completely ground, put it into a tube furnace for sintering, the temperature is 155 degrees, and the holding time is 2 hours. Take it out after cooling to room temperature naturally. Obtain MOF-S complex.

[0042] Step 3: Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com