A kind of phase change microcapsule and its preparation method and application

A technology of phase change microcapsules and phase change materials, which is applied in the direction of microcapsule preparation and microsphere preparation, and can solve the problems of uneven particle size of phase change microcapsules and uneven nucleation number distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation:

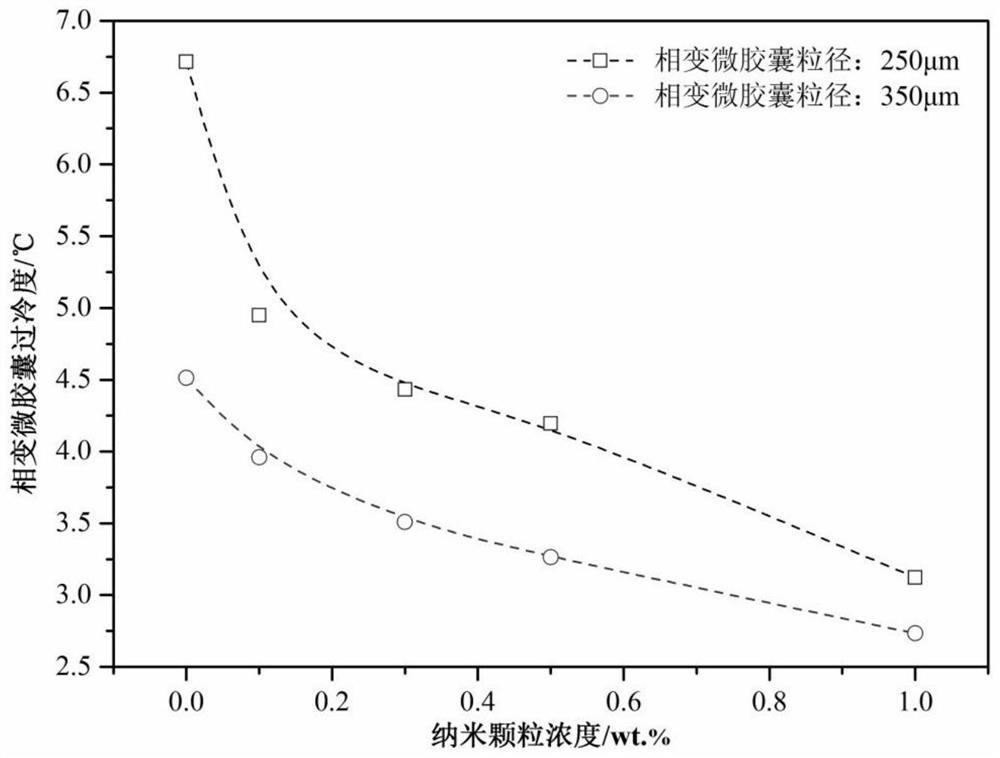

[0031] (1) Preparation of the dispersed phase of the microfluidic chip: weigh 10 g of octadecane, 0.3 g of isophorone diisocyanate, 0.15 g of 2,4-diisocyanate (TDI) and 0.01 g of , 0.03g, 0.05g and 0.1g of TiO 2 Add the nanoparticles into octadecane, stir evenly, put it into a high-power numerically controlled ultrasonic cleaner for 45 minutes, and ensure that octadecane, isophorone diisocyanate, TDI and TiO 2 The nanoparticles can be fully mixed uniformly, and the uniformly mixed mixed liquid obtained after ultrasonication is used as the dispersed phase.

[0032] (2) Preparation of the continuous phase of the microfluidic chip: Weigh 1 g of sodium dodecylbenzene sulfonate (SDBS) and pour it into 100 mL of deionized water. SDBS was evenly dispersed in deionized water, and the mixed solution obtained by stirring was used as the continuous phase.

[0033] (3) Preparation of the collection phase of the microfluidic chip: the collection phase included 1...

Embodiment 2

[0040] 1. Preparation:

[0041] (1) Preparation of the dispersed phase of the microfluidic chip: weigh 10 g of octadecane, 0.3 g of isophorone diisocyanate, 0.15 g of 2,4-diisocyanate (TDI) and 0.01 g of , 0.03g, 0.05g and 0.1g of TiO 2 Add the nanoparticles into octadecane, stir evenly, put it into a high-power numerically controlled ultrasonic cleaner for 45 minutes, and ensure that octadecane, isophorone diisocyanate, TDI and TiO 2 The nanoparticles can be fully mixed uniformly, and the uniformly mixed mixed liquid obtained after ultrasonication is used as the dispersed phase.

[0042] (2) Preparation of the continuous phase of the microfluidic chip: Weigh 1 g of sodium dodecylbenzene sulfonate (SDBS) and pour it into 100 mL of deionized water. SDBS was evenly dispersed in deionized water, and the mixed solution obtained by stirring was used as the continuous phase.

[0043] (3) Preparation of the collection phase of the microfluidic chip: the collection phase included 1...

Embodiment 3

[0050] 1. Preparation:

[0051] (1) Preparation of the dispersed phase of the microfluidic chip: weigh 10 g of octadecane, 0.3 g of isophorone diisocyanate, 0.15 g of 2,4-diisocyanate (TDI) and 0.01 g of , 0.03g, 0.05g and 0.1g of TiO 2 Add the nanoparticles into the octadecane, stir evenly, put it into a high-power numerically controlled ultrasonic cleaner and sonicate for 45 minutes to ensure that the octadecane, isophorone diisocyanate, TDI and ZnO nanoparticles can be fully mixed evenly, and the obtained The homogeneous mixture is used as the dispersed phase.

[0052] (2) Preparation of the continuous phase of the microfluidic chip: Weigh 1 g of sodium dodecylbenzene sulfonate (SDBS) and pour it into 100 mL of deionized water. SDBS was evenly dispersed in deionized water, and the mixed solution obtained by stirring was used as the continuous phase.

[0053] (3) Preparation of the collection phase of the microfluidic chip: the collection phase included 100 mL of deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| atomic number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com