Preparation method of tellurium nanowire material, tellurium nanowire material and device

A technology of tellurium nanowires and tellurium powder, which is applied in the preparation of tellurium nanowire materials, tellurium nanowire materials and devices, can solve problems such as complex processes, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing tellurium nanowires on a silicon dioxide / silicon substrate, comprising the following steps:

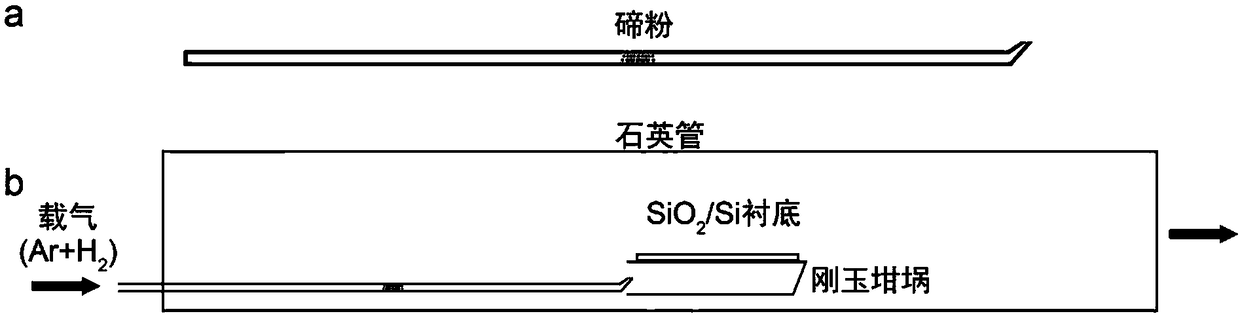

[0032] Step 1: Process the single end of the quartz tube with a diameter of 1.2cm into a quartz nozzle with a diameter of about 1mm, the structure is as follows figure 1 shown;

[0033] Step 2: Cut the silica / silicon substrate into a 2cm*4cm sheet and blow it off with an air gun, and place it on the corundum crucible face down; place the corundum crucible in the quartz tube so that the nozzle is facing the silica side, structured as figure 1 shown.

[0034] Step 3: first pass 100 sccm of argon gas into the quartz tube for 30 minutes to completely remove the residual oxygen in the tube. Switch the gas path, then feed 50 sccm of argon and 20 sccm of hydrogen into the quartz tube of the quartz nozzle, and heat the tube-type atmosphere furnace to 750°C with a heating rate of 37.5°C / min and hold for 4 minutes. Then turn off the hea...

Embodiment 2

[0037] This embodiment provides a method for preparing tellurium nanowires on a silicon dioxide / silicon substrate, comprising the following steps:

[0038] Step 1: Process the single end of the quartz tube with a diameter of 1.2cm into a quartz nozzle with a diameter of about 1mm, the structure is as follows figure 1 shown;

[0039] Step 2: Cut the silica / silicon substrate into a 2cm*4cm sheet and blow it off with an air gun, and place it on the corundum crucible face down; place the corundum crucible in the quartz tube so that the nozzle is facing the silica side, structured as figure 1 shown.

[0040] Step 3: first pass 100 sccm of argon gas into the quartz tube for 30 minutes to completely remove the residual oxygen in the tube. Switch the gas path, then feed 60 sccm of argon and 10 sccm of hydrogen into the quartz tube of the quartz nozzle, and heat the tube-type atmosphere furnace to 700°C with a heating rate of 35°C / min and keep it warm for 30min. Then turn off the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com