Preparation method of monodisperse mesoporous silica nano-sheet material

A mesoporous silica and nanosheet technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of small pore size, length of template agent chain, etc., and achieve the effect of high repetition rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

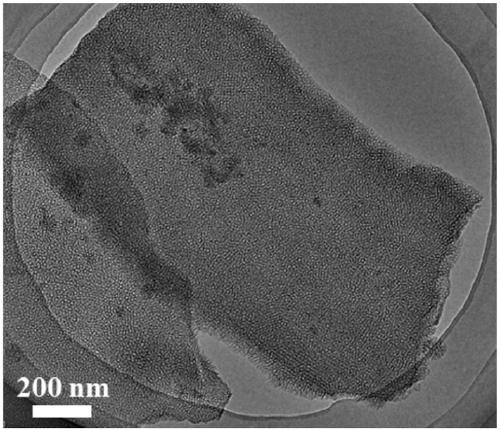

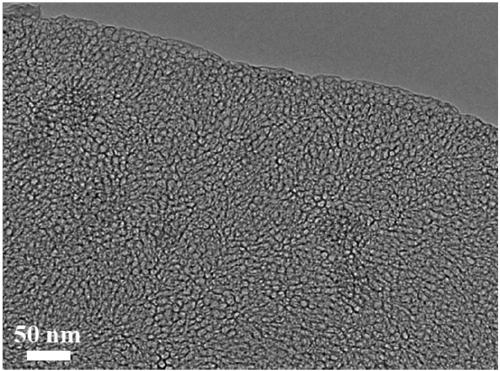

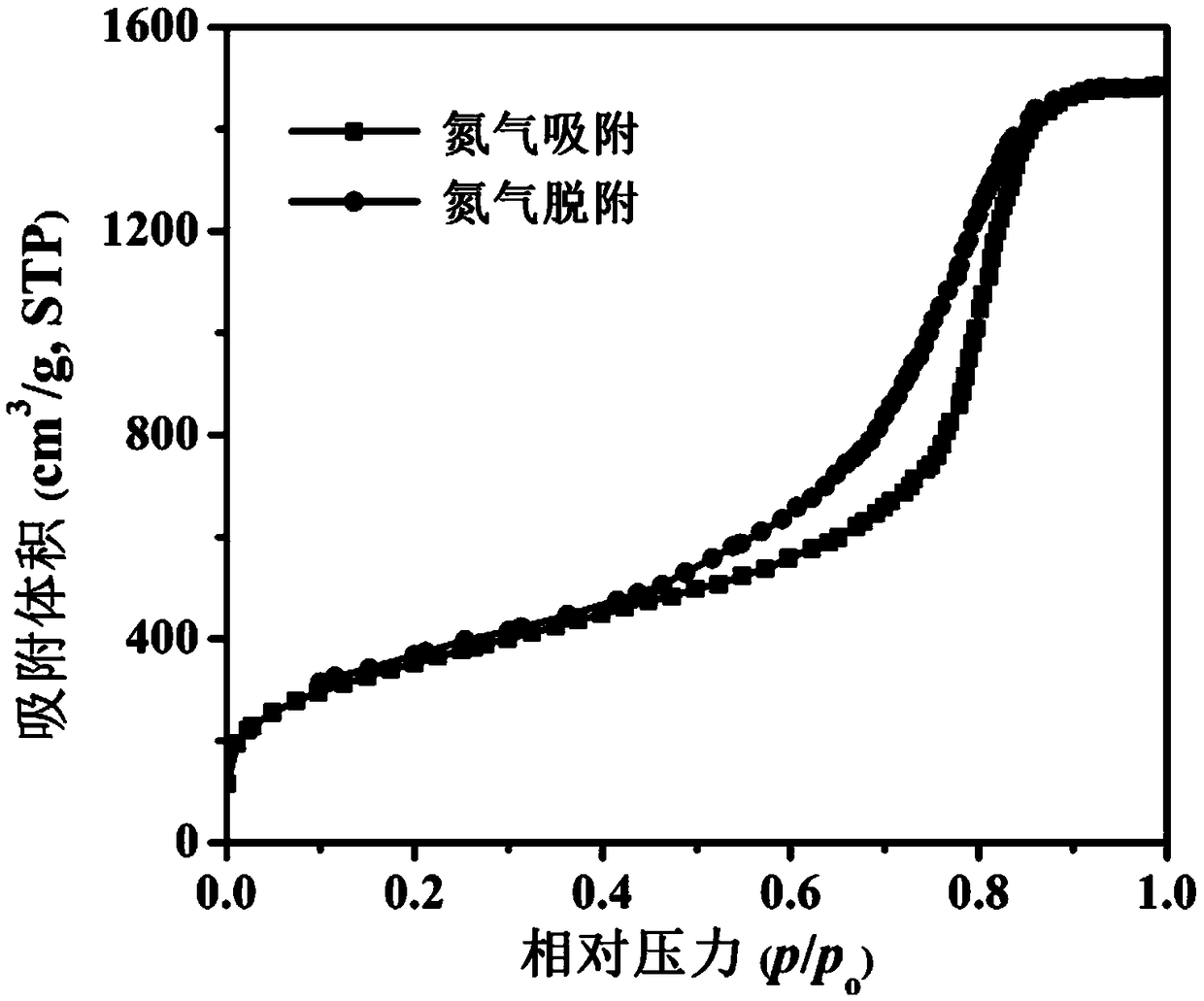

[0036] A method for preparing a monodisperse mesoporous silica nanosheet material, comprising:

[0037] (1) Dissolve 5.0g of cetyltrimethylammonium chloride and 0.12mL of diethanolamine in 20mL of deionized water successively, stir at high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reactor and stirring (speed is 1000 rev / min), the time is 0.5h;

[0038] Add 20mL cyclohexane to the above solution to obtain an oil-water miscible system;

[0039] Add 0.4mL tetraethyl orthosilicate to the above oil-water miscible system to form a new oil-water miscible system;

[0040] (2) React the oil-water miscible system in step (1) in an oil bath at a temperature of 20°C for 10 hours; after the reaction, collect the precipitate by centrifugation, wash with water and ethanol three times respectively, and obtain monodisperse mesoporous silica nanosheets ;

[0041] (3) Place the above-mentioned monodisperse mesoporous silica nanoshe...

Embodiment 2

[0046] (1) Dissolve 8.0g of cetyltrimethylammonium chloride and 0.5mL of triethanolamine in 20mL of deionized water successively, stir at high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reactor and stirring (speed is 1800 rev / min), the time is 0.5h;

[0047] Add 15mL of decahydronaphthalene to the above solution to obtain an oil-water miscible system;

[0048] Add 5mL of sodium silicate to the above oil-water miscible system to form a new oil-water miscible system;

[0049] (2) React the oil-water miscible system in step (1) in an oil bath at a temperature of 10°C for 18 hours; after the reaction, collect the precipitate by centrifugation, wash with water and ethanol three times respectively, and obtain monodisperse mesoporous silica nanosheets ;

[0050] (3) Place the above-mentioned monodisperse mesoporous silica nanosheets in a muffle furnace, raise the temperature from room temperature to 1000°C at 0.25°C / min i...

Embodiment 3

[0055] (1) Dissolve 3g of octadecyltrimethylammonium chloride and 0.75mL of ammonia successively into 20mL of deionized water, stir at a high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reactor and Stir (speed is 1500 rev / min), the time is 1.5h;

[0056] Add 10 mL of octadecene to the above solution to obtain an oil-water miscible system;

[0057] Add 2.5mL tetraethyl orthosilicate to the above oil-water miscible system to form a new oil-water miscible system;

[0058] (2) React the oil-water miscible system in step (1) in an oil bath at a temperature of 45°C for 10 hours; after the reaction, collect the precipitate by centrifugation, wash with water and ethanol three times respectively, and obtain monodisperse mesoporous silica nanosheets ;

[0059] (3) Place the above-mentioned monodisperse mesoporous silica nanosheets in a muffle furnace, raise the temperature from room temperature to 370°C at 2.5°C / min in an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com