Composite modified anti-rut agent and preparation method thereof

An anti-rutting agent and composite modification technology, which is applied in the field of road engineering materials, can solve the problems of infiltration of alkaline substances, occupation of land resources, and pollution of groundwater sources, etc., to achieve comprehensive cost reduction, significant environmental benefits, and excellent high-temperature anti-rutting performance and effect of low temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

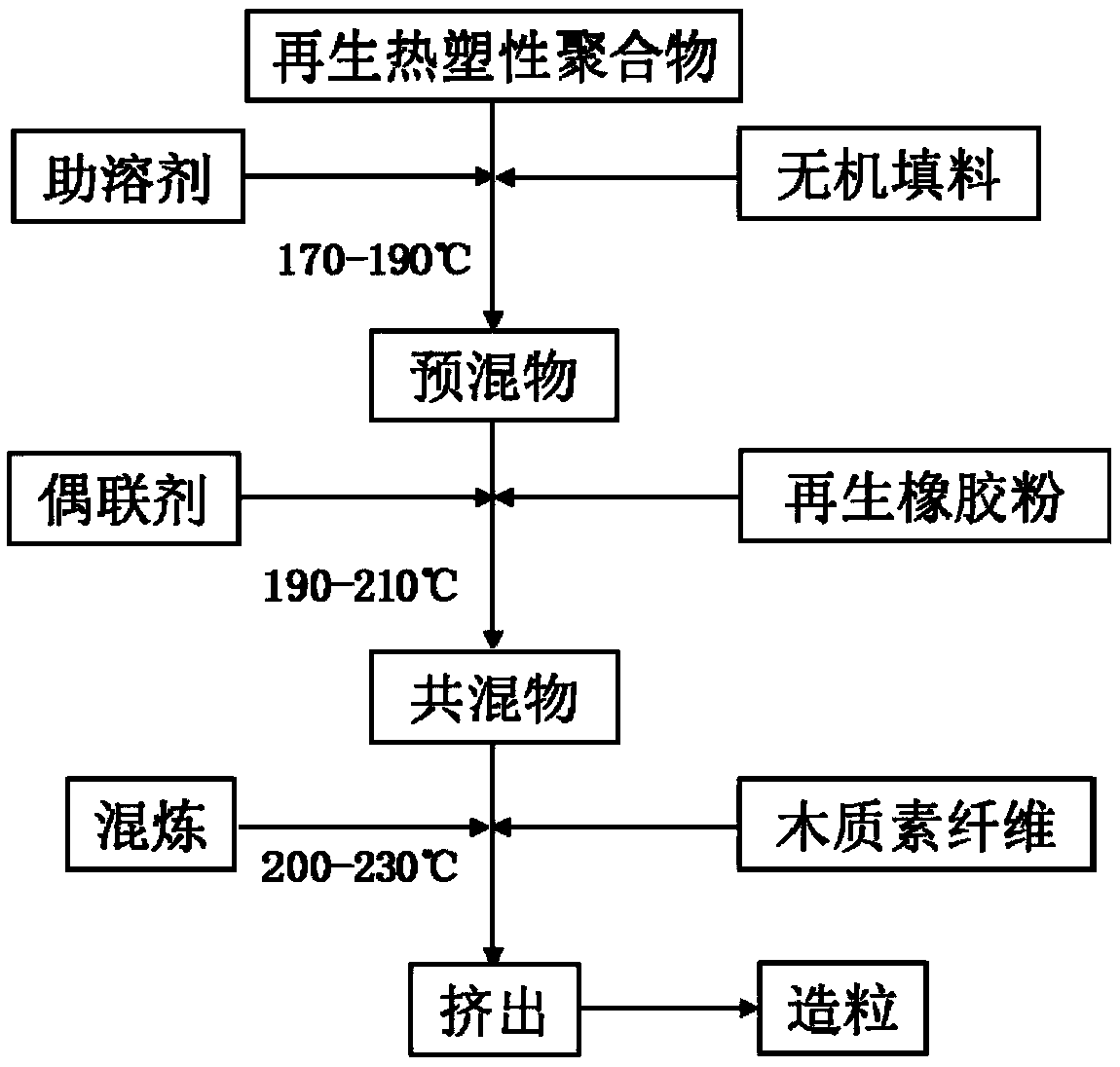

Method used

Image

Examples

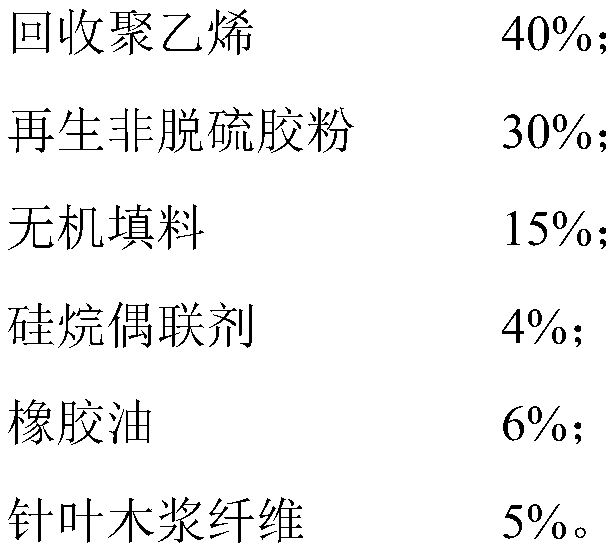

Embodiment 1

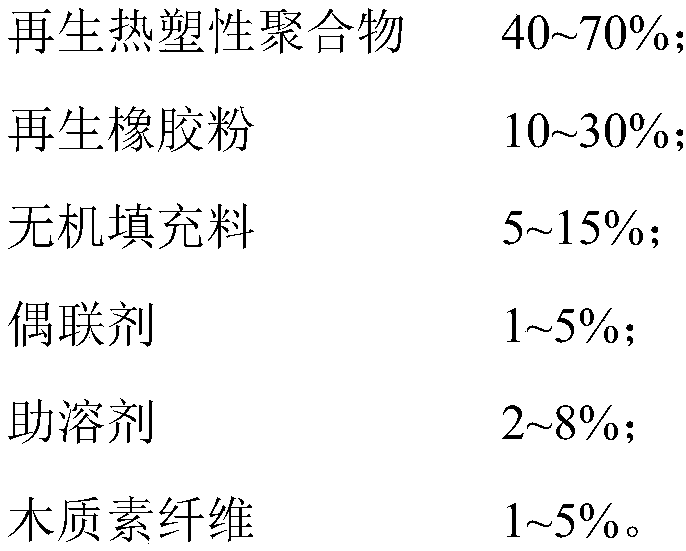

[0044] 1. A composite modified anti-rutting agent, in terms of mass percentage, comprising the following components:

[0045]

[0046] The inorganic filler is a mixture of red mud and slaked lime in the sintering process of Shanlv Group, with a mass ratio of 9:1. The particle size of the regenerated thermoplastic polymer is 2-4 mm, and the particle size of the regenerated rubber powder is 40-80 mesh. The particle size of the inorganic filler is 200-400 mesh.

[0047] 2. The preparation method of the above-mentioned composite modified anti-rutting agent is as follows:

[0048] (1) Heat the recovered polyethylene to 170°C, add rubber oil and inorganic filler in sequence at a stirring speed of 100 rpm, and fully stir to form a premix;

[0049] (2) Add regenerated non-desulfurized rubber powder to the premix in step (1) and raise the temperature to 190° C., and stir for 5 minutes at a stirring speed of 300 rpm; then add a certain proportion of silane coupling agent, Change t...

Embodiment 2

[0052] 1. A composite modified anti-rutting agent, in terms of mass percentage, comprising the following components:

[0053]

[0054] The inorganic filler is a mixture of red mud and slaked lime in the sintering process of Shanlv Group, with a mass ratio of 8:2. The particle size of the regenerated thermoplastic polymer is 2-4 mm, and the particle size of the regenerated rubber powder is 40-80 mesh. The particle size of the inorganic filler is 200-400 mesh.

[0055] 2. The preparation method of the above-mentioned composite modified anti-rutting agent is as follows:

[0056] (1) Heating the recovered polypropylene to 180°C, adding aromatic oil and inorganic filler in sequence at a stirring speed of 200 rpm, and fully stirring to form a premix;

[0057] (2) Add regenerated desulfurized rubber powder to the premix and raise the temperature to 2000°C, and stir for 5 minutes at a stirring speed of 400rpm; then add a certain proportion of aluminate coupling agent, and replace...

Embodiment 3

[0060] 1. A composite modified anti-rutting agent, in terms of mass percentage, comprising the following components:

[0061]

[0062] The inorganic filler is a mixture of red mud and slaked lime in the sintering process of Shanlv Group, with a mass ratio of 7:3. The particle size of the regenerated thermoplastic polymer is 2-4 mm, and the particle size of the regenerated rubber powder is 40-80 mesh. The particle size of the inorganic filler is 200-400 mesh.

[0063] 2. The preparation method of the above-mentioned composite modified anti-rutting agent is as follows:

[0064] (1) Heating the recovered polyvinyl chloride to 180°C, adding aromatic oil and inorganic filler in sequence at a stirring speed of 300 rpm, and fully stirring to form a premix;

[0065] (2) Add regenerated non-desulfurized rubber powder to the premix and raise the temperature to 205°C, and stir for 5 minutes at a stirring speed of 500rpm; then add a certain proportion of aluminum-titanium composite c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com