System and preparation method for preparing accelerant N,N'-thiocarbanilide via continuous reaction

A technology of diphenylthiourea and accelerator, which is applied in the field of continuous reaction preparation of accelerator N, can solve the problems of reaction product yield influence, environmental pollution, waste liquid discharge, etc., achieves small footprint, saves water resources, The effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

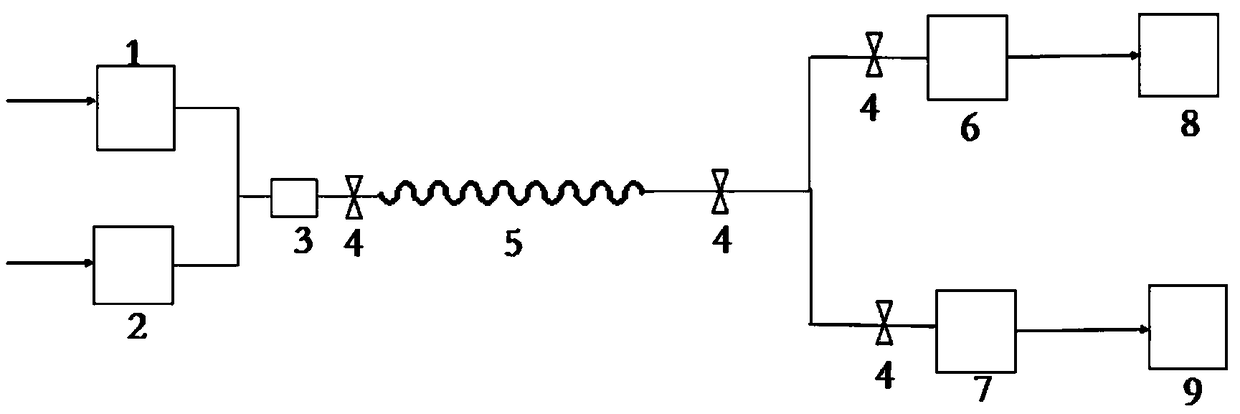

Method used

Image

Examples

Embodiment 1

[0052] (1) adding sulfur to carbon disulfide according to mass fraction 2% to completely dissolve sulfur;

[0053] (2) Aniline and carbon disulfide / sulfur are injected through a high-pressure plunger pump at the same time with a flow rate of 27ml / min and 10ml / min respectively, fully mixed through an in-line mixer, and then entered into a steel tubular reactor with an internal diameter of 2cm to react, The length of the tubular reactor is 18m, the temperature of the tubular reactor is 200°C, and the internal pressure of the tubular reactor is maintained at 5MPa;

[0054] (3) The reaction solution flows forward under the push of the high-pressure plunger pump, and exits the tubular reactor after about 150 minutes;

[0055] (4) After the gas hydrogen sulfide produced by the reaction comes out from the tubular reactor, it enters the gas storage tank and is directly absorbed with sodium hydroxide lye;

[0056] (5) After the liquid component produced by the reaction comes out of th...

Embodiment 2

[0061] (1) adding sulfur to carbon disulfide according to 5% by mass fraction to completely dissolve the sulfur;

[0062] (2) Inject aniline and carbon disulfide / sulfur into a high-pressure plunger pump at the same time at a flow rate of 55ml / min and 35ml / min respectively, mix fully through an online mixer, and then enter a steel tubular reactor with an inner diameter of 3cm for mixed reaction , the length of the tubular reactor is 25m, and the temperature of the tubular reactor is heated at 175°C; the internal pressure of the tubular reactor is maintained at 7MPa;

[0063] (3) The reaction solution flows forward under the push of the high-pressure plunger pump, and exits the tubular reactor after about 200 minutes;

[0064] (4) After the gas hydrogen sulfide produced by the reaction comes out from the tubular reactor, it enters the gas storage tank and is directly absorbed with sodium hydroxide lye;

[0065] (5) After the liquid component produced by the reaction comes out o...

Embodiment 3

[0069] (1) Inject aniline and carbon disulfide through a high-pressure plunger pump at the same time at flow rates of 60ml / min and 40ml / min respectively, mix thoroughly through an online mixer, and then enter a steel tubular reactor with an inner diameter of 2cm for reaction. The length of the reactor is 48m, and the temperature of the heated tubular reactor is 250°C; the internal pressure of the tubular reactor is maintained at 7MPa;

[0070] (2) The reaction solution flows forward under the push of the high-pressure plunger pump, and exits the tubular reactor after about 150 minutes;

[0071] (3) After the gas hydrogen sulfide produced by the reaction comes out from the tubular reactor, it enters the gas storage tank and is directly absorbed with sodium hydroxide lye;

[0072] (4) After the liquid component produced by the reaction comes out of the tubular reactor, it enters the product receiving tank, and ethyl acetate solvent is added, and the product N, N'-diphenylthioure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com