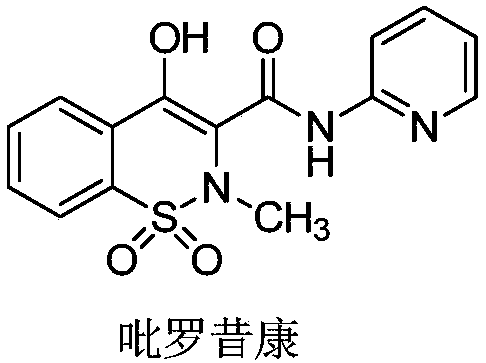

Method for purifying piroxicam

A purification method and technology of piroxicam, applied in the field of chemical medicine, can solve the problems of high solvent toxicity, large solvent consumption and high purification cost, and achieve the effects of high-purity purification and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get 10g of piroxicam crude product, HPLC purity 98.954%, main impurity 0.698%, join in the mixed solution of 50g dioxane and 50g xylene, heat up and reflux, until dissolving completely (solution becomes clear). Remove the insoluble matter by suction filtration while it is hot, and cool the filtrate to room temperature, a large amount of solids can be seen to precipitate, and then suction filtration, the obtained filter cake is dried under reduced pressure at 80°C to obtain the pure product of piroxicam. The yield is 77%, the HPLC purity is 99.456%, the main impurity is 0.442%, and the calculated impurity removal rate is 36.7%.

Embodiment 2

[0036] Get 10g of piroxicam crude product, HPLC purity 98.954%, main impurity 0.698%, join in the mixed solution of 50g dioxane and 100g xylene, heat up and reflux, until dissolving completely (solution becomes clear). Remove the insoluble matter by suction filtration while it is hot, and cool the filtrate to room temperature, a large amount of solids can be seen to precipitate, and then suction filtration, the obtained filter cake is dried under reduced pressure at 80°C to obtain the pure product of piroxicam. The yield is 78.6%, the HPLC purity is 99.517%, the main impurity is 0.442%, and the calculated impurity removal rate is 44.7%.

Embodiment 3

[0038] Get 5g of piroxicam crude product, HPLC purity 99.456%, main impurity 0.442%, join in the mixed solution of 6.67g dioxane and 13.3g xylene, heat up and reflux to dissolve completely (solution becomes clear). Remove the insoluble matter by suction filtration while it is hot, and cool the filtrate to room temperature, a large amount of solids can be seen to precipitate, and then suction filtration, the obtained filter cake is dried under reduced pressure at 80°C to obtain the pure product of piroxicam. The yield is 92%, the HPLC purity is 99.730%, the main impurity is 0.242%, and the calculated impurity removal rate is 45.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com