A kind of preparation method of block copolymer with light response, reduction response and pH response

A block copolymer and light-responsive technology, which is applied in the field of block copolymer preparation, can solve the problems such as the decrease of the hydrophilic ability of acrylic acid, and achieve good entrapment and controlled release performance, good stability, and good multiple responsiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Synthesis of PtBAn macromolecular chain transfer agent

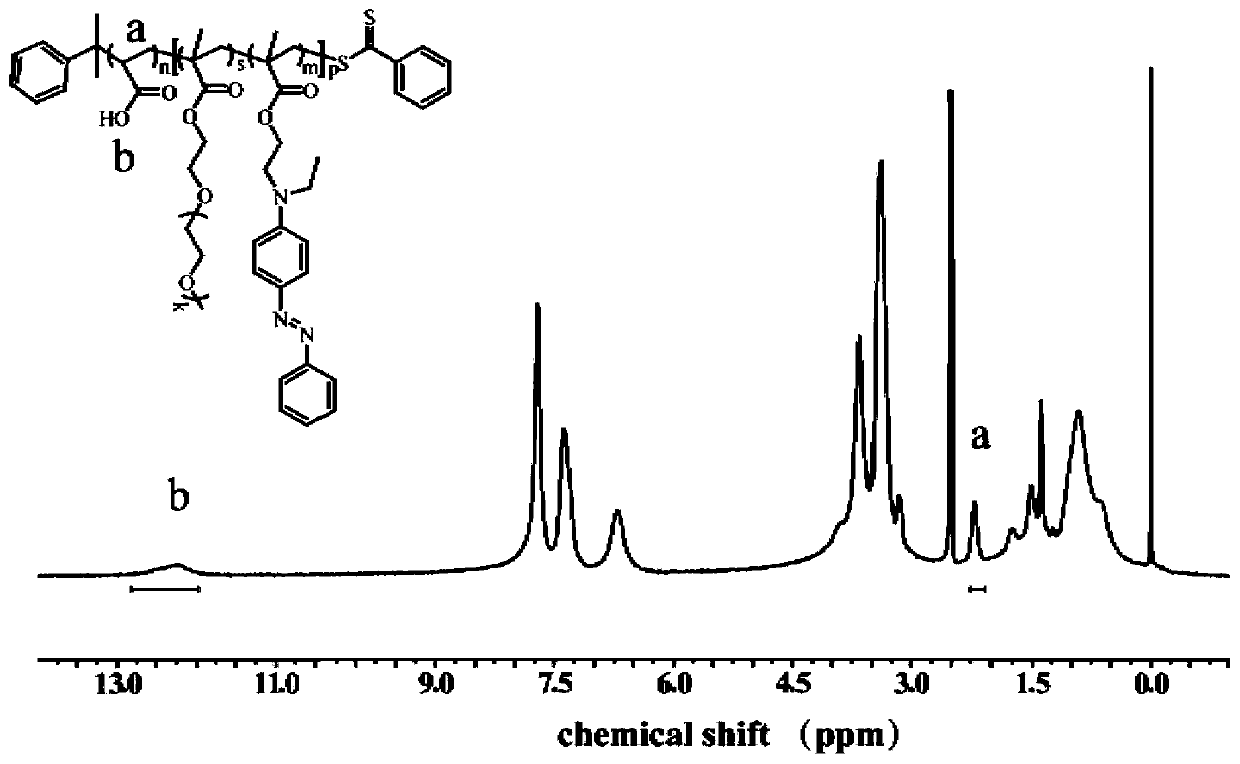

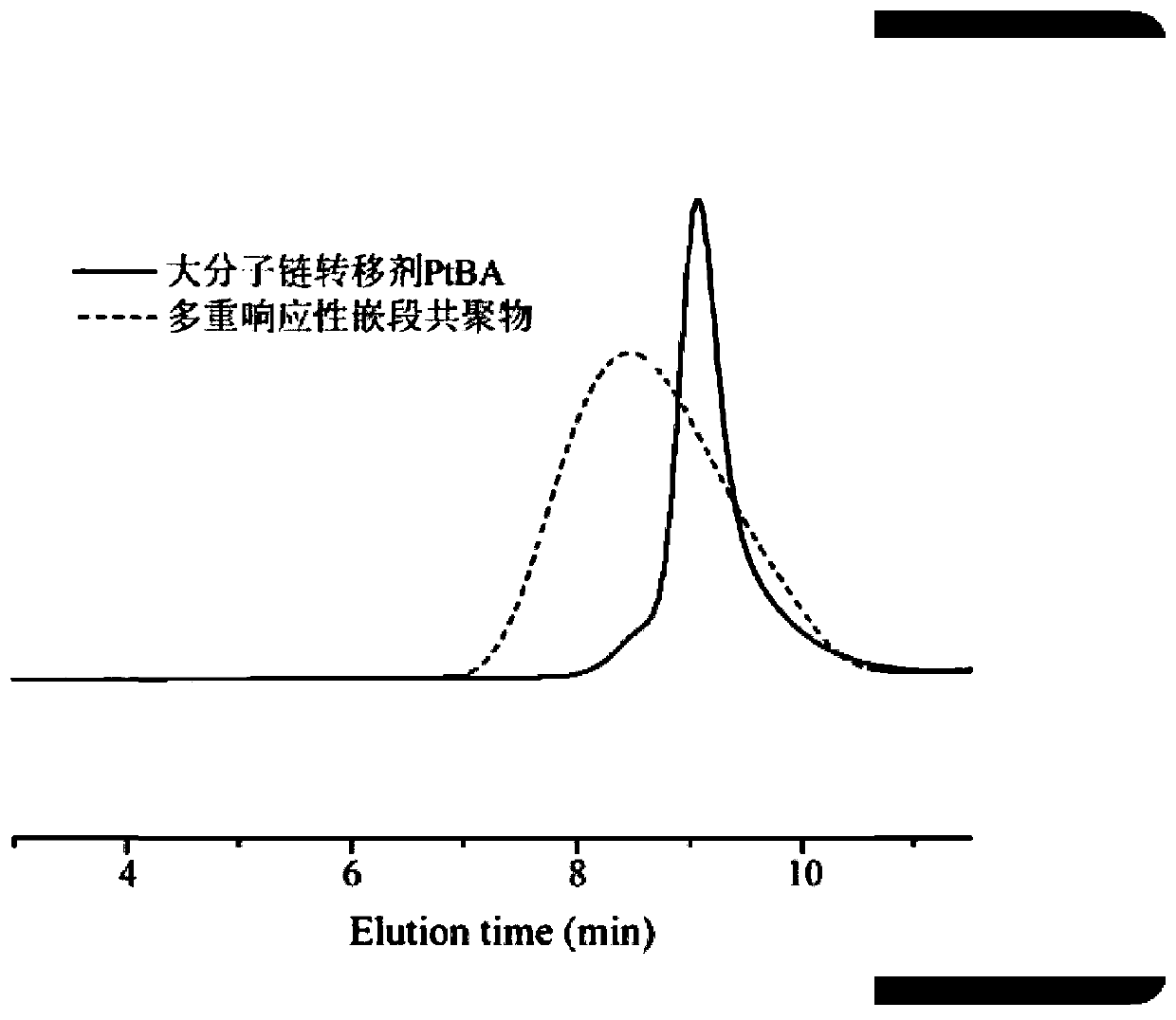

[0038] Tert-butyl acrylate (2.56g), cumyl dithiobenzoate CDB (0.054g) and azobisisobutyronitrile (0.0064g) were dissolved in 4mL of tetrahydrofuran, and after several freeze-thaw degassing operations, After ensuring that the solvent no longer contains air, argon gas was passed into it, and after 24 hours of reaction at 65°C, it was quenched with liquid nitrogen to stop the reaction, and the ratio of methanol:water=2:1 was used as the first precipitant, and the precipitation was repeated for 3 time, then dry to obtain the product PtBA macromolecular chain transfer agent (GPC curve such as figure 2 shown);

[0039] 2) PAA n -b-P(PEGMA x -co-AzoMA y ) m Synthesis of Block Copolymers

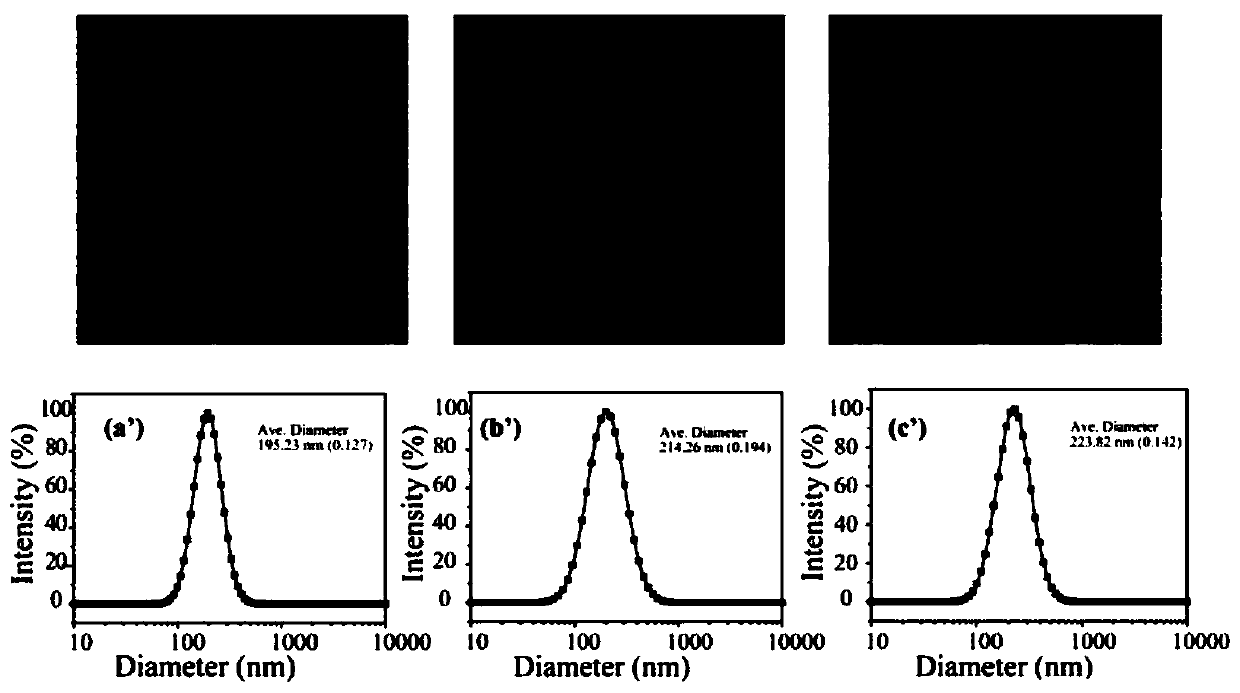

[0040]Take the PtBA macromolecular chain transfer agent (0.8g), AIBN (0.032g), azobenzene monomer (1.68g) and PEGMA (0.118g) synthesized in step 1) and dissolve them in 6mL of tetrahydrofuran. Gas operation, after ensuring th...

Embodiment 2

[0042] 1) Synthesis of PtBAn macromolecular chain transfer agent

[0043] Tert-butyl acrylate (2.56g), cumyl dithiobenzoate CDB (0.054g) and azobisisobutyronitrile (0.0064g) were dissolved in 4mL of tetrahydrofuran, and after continuous freeze-thaw degassing operations, After ensuring that the solvent no longer contains air, argon gas was introduced, and after 24 hours of reaction at 65 ° C, it was quenched with liquid nitrogen to stop the reaction. The ratio of methanol: water = 3: 1 was used as the first precipitant, and the precipitation was repeated for 3 time, then dry to obtain the product PtBA macromolecular chain transfer agent;

[0044] 2) PAA n -b-P(PEGMA x -co-AzoMA y ) m

[0045] Get step 1) synthetic PtBA macromolecular chain transfer agent (0.8g), AIBN (0.00165g), azobenzene monomer (0.7077g), PEGMA (0.118g) is dissolved in 6mL THF, through continuous freezing and thawing Gas operation, after ensuring that the solvent no longer contains air, argon gas is in...

Embodiment 3

[0048] 1) Synthesis of PtBAn macromolecular chain transfer agent

[0049] Tert-butyl acrylate (3.84g), cumyl dithiobenzoate CDB (0.054g) and azobisisobutyronitrile (0.0066g) were dissolved in 4mL of tetrahydrofuran, and after continuous freeze-thaw degassing operations, After ensuring that the solvent no longer contains air, argon gas was introduced, and after 24 hours of reaction at 65 ° C, it was quenched with liquid nitrogen to stop the reaction. The ratio of methanol: water = 3: 1 was used as the first precipitant, and the precipitation was repeated for 3 time, then dry to obtain the product PtBA macromolecular chain transfer agent;

[0050] 2) PAAn-b-P(PEGMAx-co-AzoMAy)m

[0051] Get step 1) synthetic PtBA macromolecular chain transfer agent (0.775g), AIBN (0.00165g), azobenzene monomer (0.5055g), PEGMA (0.118g) is dissolved in 6mL tetrahydrofuran, through continuous freeze-thaw Gas operation, after ensuring that the solvent no longer contains air, argon gas is introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com