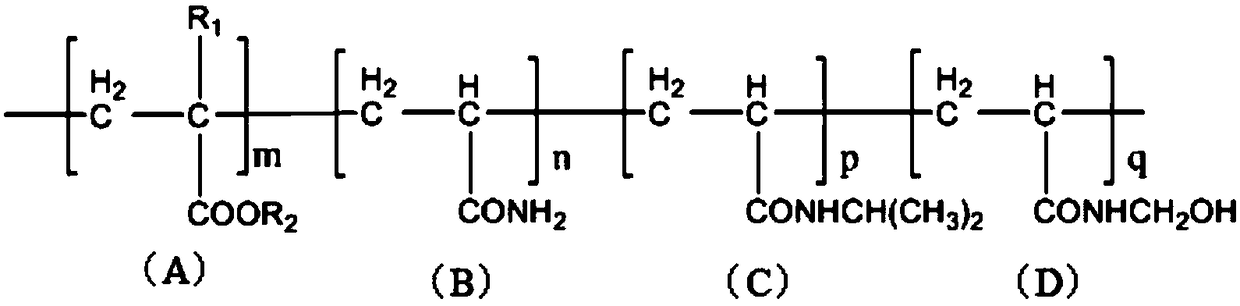

Sustained-release silicone oil hydrogel and application thereof in marine antifouling coatings

A marine antifouling and hydrogel technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as self-repair cannot be achieved, shorten the self-repair cycle and increase branched chains Quantity, the effect of increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

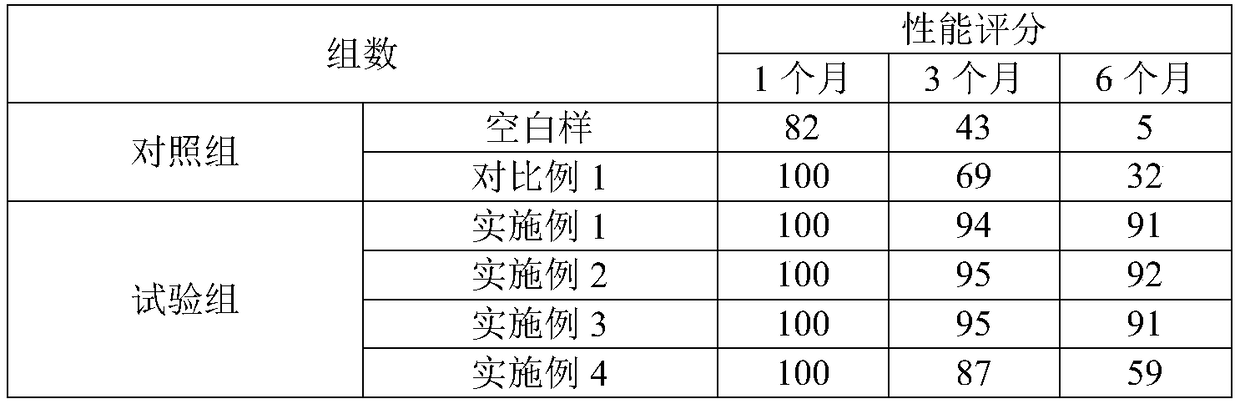

Examples

Embodiment 1

[0027] A kind of preparation of the hydrogel of slow-release silicone oil, the concrete steps of preparation are:

[0028] (1) At room temperature, add 20g of methyl methacrylate, 5g of N-methylolacrylamide, 20g of methyl silicone oil, and 0.1g of sodium lauryl sulfate into the emulsification disperser, and ultrasonically disperse with an ultrasonic disperser for 1h , and then add 1.2 g of azobisisobutyronitrile under stirring at a low speed of 280 r / min, and mix to obtain a premix.

[0029] (2) Add 150mL of water, 25g of acrylamide, and 0.1g of sodium lauryl sulfate into a four-necked reaction flask equipped with a stirrer, an addition funnel, a reflux condensing device, and a thermometer, stir and mix well, and heat up to 50°C , and then drop the premix into the mixed solution of acrylamide and sodium lauryl sulfate at a constant rate of 0.65mL / min, stir the mixed solution at a rate of 900r / min while adding it, and keep it at 50°C to continue The reaction was stirred for 10...

Embodiment 2

[0032] A kind of preparation of the hydrogel of slow-release silicone oil, the concrete steps of preparation are:

[0033] (1) At room temperature, add 18g methyl acrylate, 5g N-methylol acrylamide, 20g methyl silicone oil, 0.1g OP-10 into the emulsification disperser, stir at 3000r / min for 1h, then Add 1.2 g of azobisisoheptanonitrile under stirring at a speed of 1 / min, and mix uniformly to obtain a premix.

[0034] (2) Add 150mL of water, 23g of acrylamide, 5g of N-isopropylacrylamide, 0.1g of OP-10 into a four-necked reaction flask equipped with a stirrer, an addition funnel, a reflux condensing device, and a thermometer, and stir to mix Evenly, heat up to 50°C, then add the premixed mixture dropwise at a constant rate of 0.5mL / min to the mixed solution of acrylamide and N-isopropylacrylamide, and stir at a rate of 1400r / min while adding The solution was mixed, maintained at 50° C. and continued to stir for 10 h to obtain a hydrogel of slow-release silicone oil.

[0035] ...

Embodiment 3

[0037] A kind of preparation of the hydrogel of slow-release silicone oil, the concrete steps of preparation are:

[0038] (1) At room temperature, add 20g of methyl methacrylate, 3g of N-methylolacrylamide, 2g of N-isopropylacrylamide, 20g of methyl silicone oil, and 0.1g of TX-10 into an emulsifying disperser, and use Ultrasonic disperser was used for ultrasonic dispersion for 1 hour, then 1.3 g of benzoyl peroxide was added under stirring at a low speed of 280 r / min, and the mixture was uniformly mixed to obtain a premix.

[0039] (2) Add 150mL of water, 25g of acrylamide, and 0.1g of TX-10 into a four-necked reaction flask equipped with a stirrer, an addition funnel, a reflux condensing device, and a thermometer, stir and mix evenly, heat up to 50°C, and then The premix was added dropwise to the mixed solution of acrylamide and TX-10 at a constant rate of 0.6mL / min, and the mixed solution was stirred at a rate of 2000r / min while adding dropwise, and kept at 50°C for 10h to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com