Method for preparing corrugated-paper adhesive by using irradiation-microwave to esterify potato starch

A technology of potato starch and corrugated paper glue, which is applied in the field of corrugated paper, can solve the problems of nanocrystalline cellulose research that are rarely reported, and achieve the effect of improving performance and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

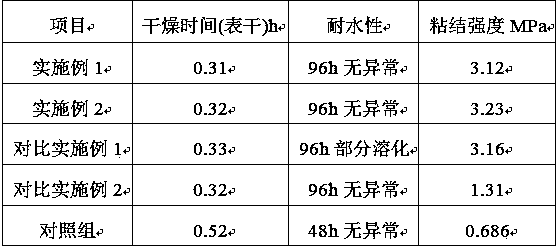

Examples

Embodiment 1

[0022] A method for preparing corrugated paper adhesive with irradiation-microwave esterified potato starch, is characterized in that, comprises the steps:

[0023] (1) Preparation of irradiation-microwave esterified potato starch:

[0024] Add deionized water to 80 parts of irradiated-microwave-treated potato starch at a ratio of 1:5, mechanically stir in a water bath at 30-35°C for 1 hour, add sodium hydroxide dropwise to control the pH to 8, and add 9 parts of esterifying agent dropwise, and react 1h, adjust the pH to 6 with hydrochloric acid, centrifuge, wash twice with ethanol solution and distilled water respectively, dry and pulverize through a 100-mesh sieve to obtain irradiation-microwave esterified potato starch;

[0025] (2) Surface modification of nanocrystalline cellulose:

[0026] Mix 3-methacryloyloxypropyltrimethoxysilane and ethanol to form a solution with a volume fraction of 8%, add hydrochloric acid dropwise to adjust the pH to 3, and perform a hydrolysis ...

Embodiment 2

[0034] A method for preparing corrugated paper adhesive with irradiation-microwave esterified potato starch, is characterized in that, comprises the steps:

[0035] (1) Preparation of irradiation-microwave esterified potato starch:

[0036] Add deionized water to 100 parts of irradiated-microwave-treated potato starch at a ratio of 1:5, mechanically stir in a water bath at 30-35°C for 2 hours, add sodium hydroxide dropwise to control the pH to 9, and add 12 parts of esterifying agent dropwise, and react 2h, adjust the pH to 7 with hydrochloric acid, centrifuge, wash with ethanol solution and distilled water 3 times respectively, dry and pulverize through a 100-mesh sieve to obtain irradiation-microwave esterified potato starch;

[0037] (2) Surface modification of nanocrystalline cellulose:

[0038] Mix 3-methacryloyloxypropyltrimethoxysilane and ethanol to form a solution with a volume fraction of 8%, add dropwise hydrochloric acid to adjust the pH to 4, carry out hydrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com