Micro-integrated electric field measuring sensor based on single-arm straight optical path structure

A technology of electric field measurement and sensor, applied in the direction of electrostatic field measurement, etc., can solve the problems of large measurement error, large geometric size of front-end components, large system error, etc., to avoid the introduction of measurement error, simplify the difficulty of preparation process, and eliminate negative effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

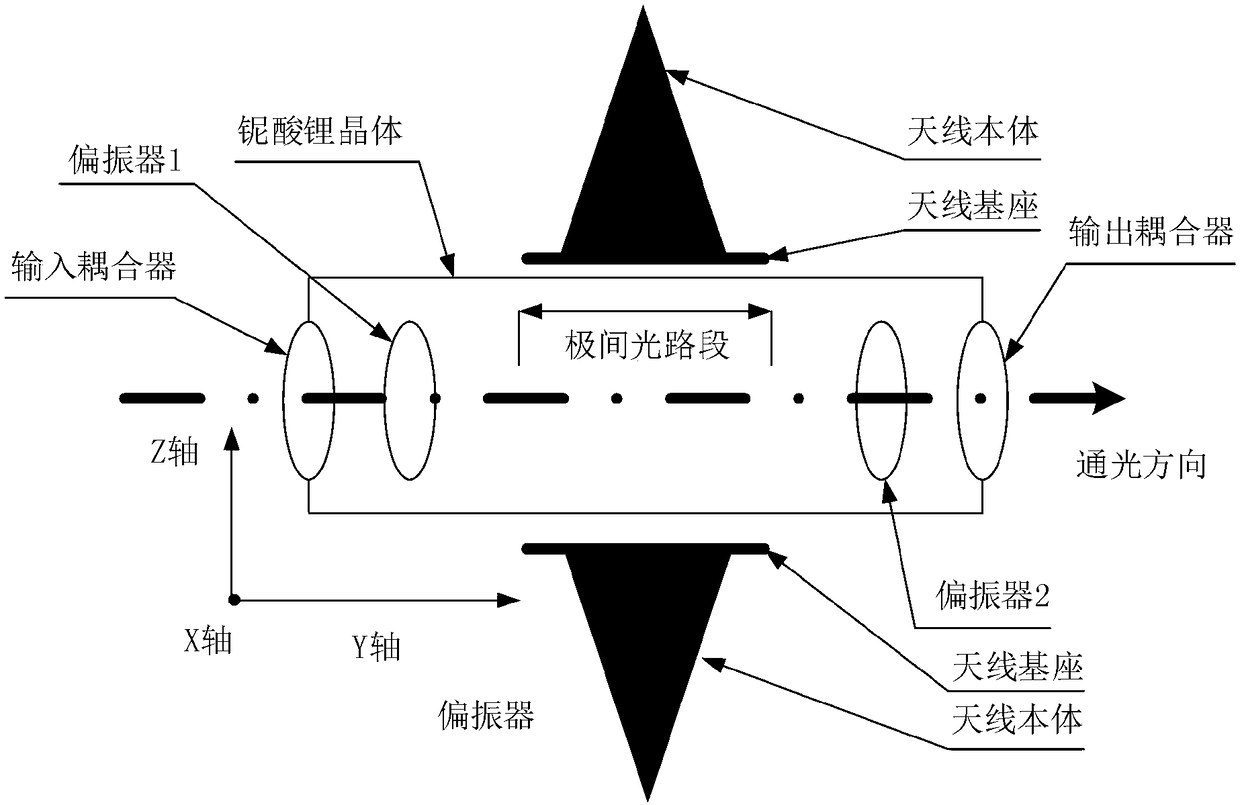

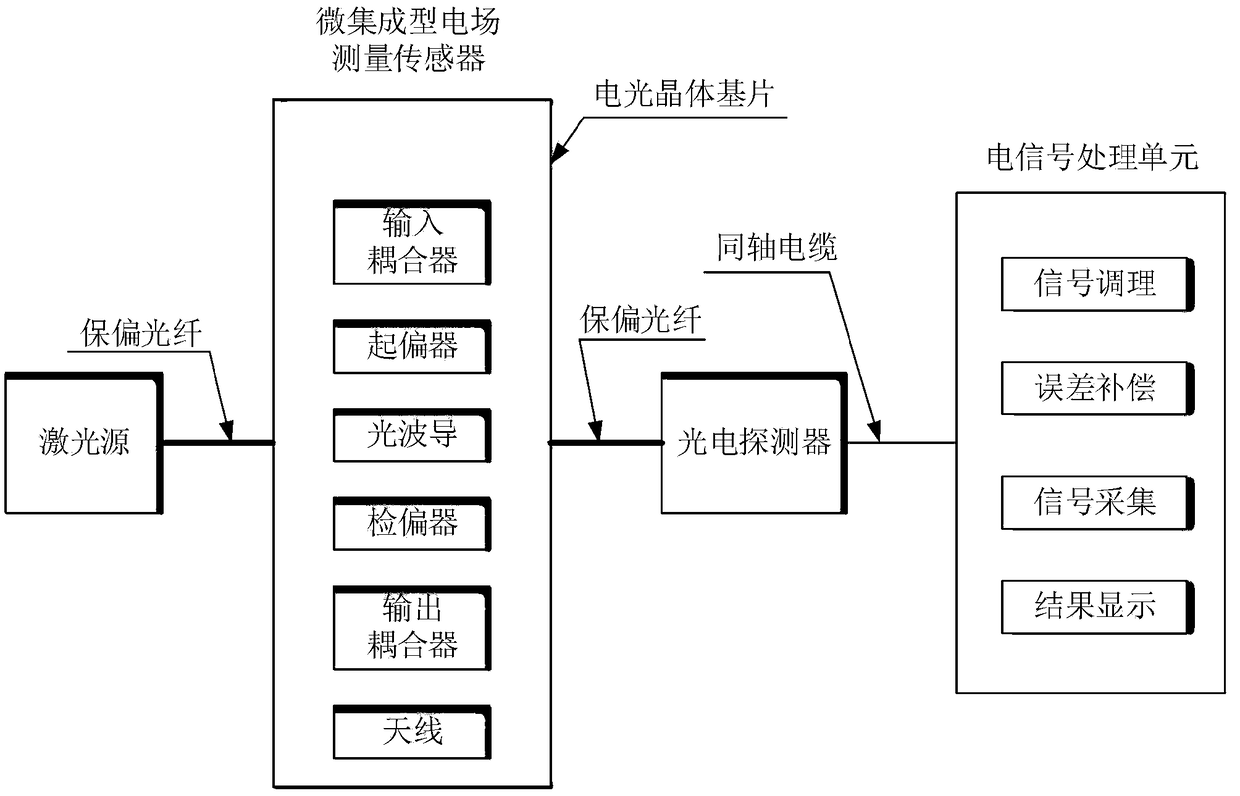

[0018] The electric field measurement sensor is the core of the present invention, and its structural diagram is as figure 1 As shown, it includes input coupler, first polarizer (polarizer 1), single-arm in-line optical path (interpolar optical path section, which is the distance between polarizer 1 and polarizer 2 at one end, and the material is lithium niobate crystal ), the second polarizer (polarizer 2), the output coupler and the detection antenna 6 parts. The whole sensor is based on lithium niobate crystal, adopts the principle of mask etching and titanium thermal diffusion, and controls the diffusion and doping of titanium elements to form a coupler, a polarizer (polarizer 1), and a single sensor inside the lithium niobate crystal. Arm in-line optical path, analyzer (polarizer 2) and output coupler 5 components, each component is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com