Preparation and application method of combined nano magnetic separating medium

A separation medium and nano-magnetic technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of fixed phase type limitation, limited flexibility, preparation difficulty, etc., and achieve stable phase structure and easy operation The effect of convenience and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

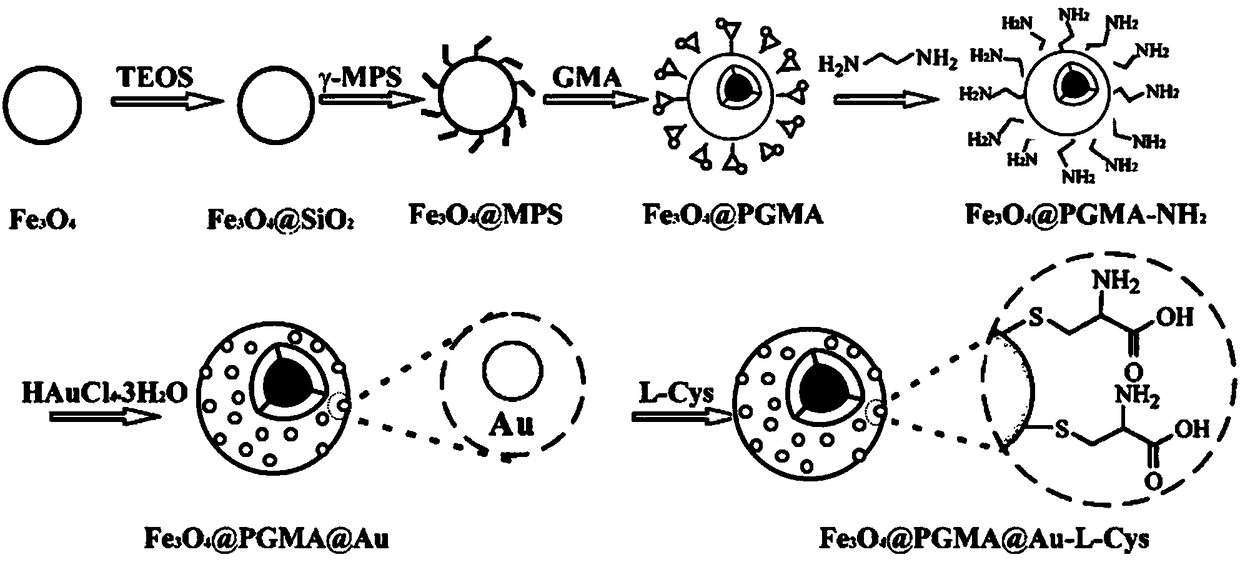

[0030] 1. Preparation of magnetic nanoparticle matrix:

[0031] The magnetic magnetic nanoparticle matrix can be obtained by direct purchase or self-preparation. The general preparation method is to firstly prepare magnetic iron oxide nanoparticles as the core of its matrix, and further coat the porous silica shell on its surface.

[0032] Prepare magnetic iron oxide nanoparticles by solvothermal method, measure 100mL of ethylene glycol and place in a 250mL three-neck flask, add 2.7g of ferric chloride hexahydrate, after ultrasonication for 10min, add 7.2g of anhydrous sodium acetate, and mechanically stir for 30min , transfer the mixed homogenate to a stainless steel autoclave lined with polytetrafluoroethylene, and react in an oven at 200°C for 8h. Afterwards, with the assistance of an external magnetic field, the magnetic nanomatrix Fe was washed with ethanol and pure water respectively and collected. 3 o 4 , dried overnight at 60°C to obtain magnetic iron oxide nanopart...

Embodiment 2

[0053] 1) Prepare magnetic iron oxide nanoparticles by solvothermal method, measure 100mL of ethylene glycol and put it in a 250mL three-necked flask, add 2.7g of ferric chloride hexahydrate, after ultrasonication for 10min, add 7.2g of anhydrous sodium acetate, and mechanically stir After 30 minutes, the mixed homogenate was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and reacted in an oven at 200°C for 8 hours. Afterwards, with the assistance of an external magnetic field, the magnetic nanomatrix Fe was washed with ethanol and pure water respectively and collected. 3 o 4 , dried overnight at 60°C to obtain magnetic iron oxide nanoparticles.

[0054] 2) Weigh 150mg of the above-mentioned Fe 3 o 4 The particles were evenly dispersed in a mixed solution of 160mL ethanol, 40mL water and 2mL ammonia water, sonicated for 30min, 1.5mL TEOS was added dropwise, and mechanically stirred at room temperature for 8h. Magnetic separation, followed by...

Embodiment 3

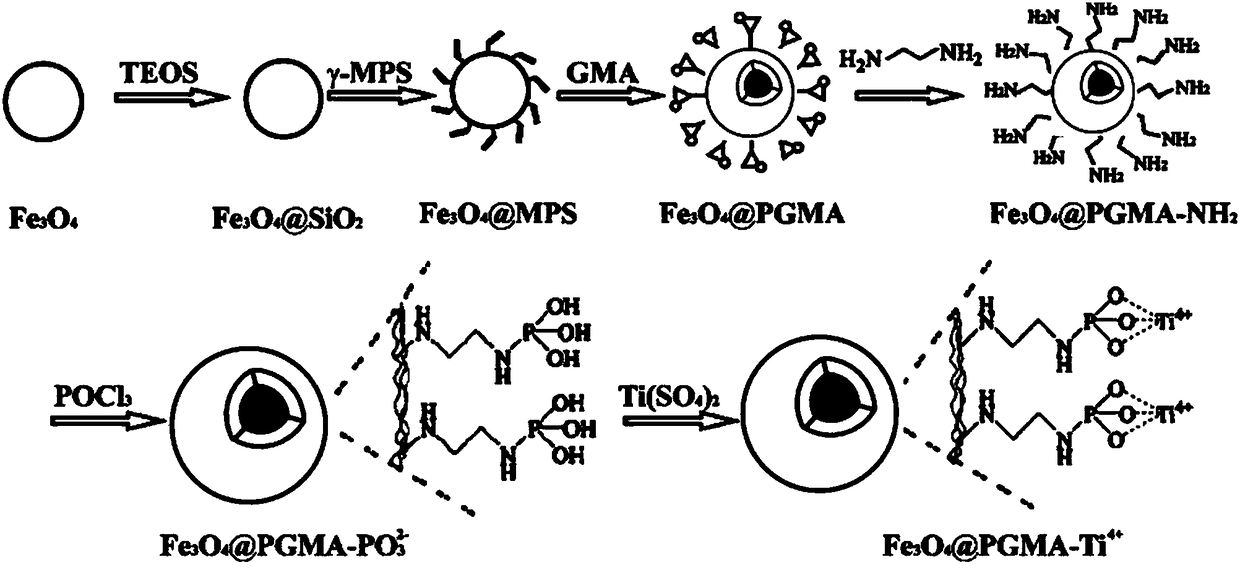

[0062] Same as Example 1, the difference is the preparation of functionalized magnetic nano-separation medium in step 3: get 50 of the above-mentioned magnetic nano-material Fe 3 o 4 @SiO 2 @PGMA-NH2 was dispersed in 80 mL of ACN solution containing 60 mmol L-1 2,4,6-collidine. After passing nitrogen gas for 10 minutes, add 800 μL phosphorus oxychloride. Under nitrogen protection, stir at room temperature for 12h. The obtained material is washed with acetonitrile and water, and dried at 50° C. to obtain a magnetic nanometer material for enrichment and separation of selective phosphopeptides in dispersed biological samples. see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com