Method and catalyst for preparing ethanol from lignocellulosic biomass in one step

A technology of lignocellulose and catalysts, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, and preparation of hydroxyl compounds. It can solve the problems of low carbon yield of target products, easy repolymerization of oligomers or small molecules, and achieve Hydrothermal stability Recyclable, high hydrothermal stability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

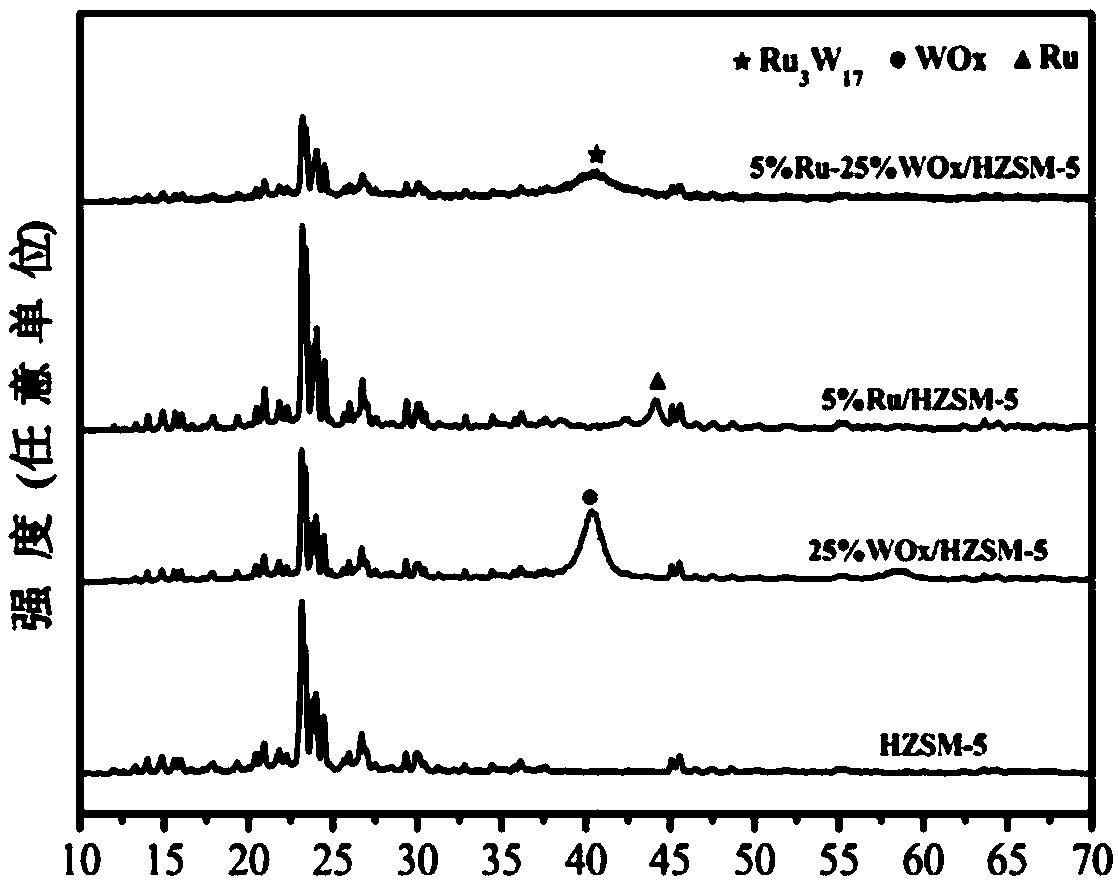

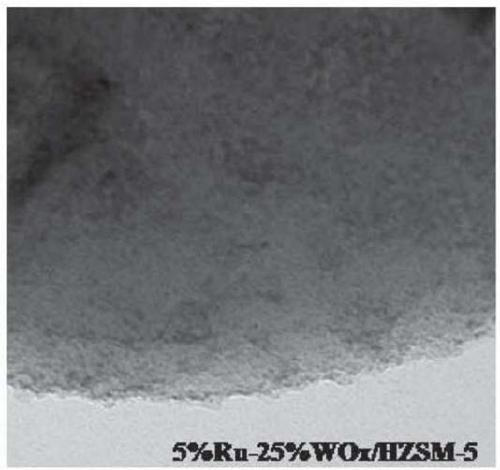

[0047] Preparation of 5%Ru-25%WOx / HZSM-5 Bimetallic Heterogeneous Catalyst

[0048] According to the aforementioned general method, 155.8 mg of RuCl 3 Hydrate and 402.4mg of (NH 4 ) 6 h 2 W 12 o 40 The hydrate was dissolved in 120 g of distilled water to obtain an aqueous solution, and 1.2 g of HZSM-5 molecular sieve was ground and dispersed in water to obtain a dispersion. Then the obtained aqueous solution was added to the obtained dispersion, and after stirring at 60°C for 15h, the solvent was removed by rotary evaporation, followed by drying at 100°C for 8h, and finally the obtained catalyst precursor was placed in a 600°C Reduction in hydrogen atmosphere for 3h, thus obtaining the desired bimetallic heterogeneous catalyst.

[0049] By an elemental analyzer, it is determined that the mass content of metal Ru in the obtained bimetallic heterogeneous catalyst is 5%, and the mass content of metal W is 25%, that is, 5%Ru-25%WOx / HZSM-5 bimetallic heterogeneous catalyst. ...

Embodiment 2

[0053]With the same preparation and characterization procedures as in Example 1, except changing the amount of supported metal and the type and amount of support, the mass fraction of metal Ru shown in Table 1 was prepared at 0.5%-10% and the mass fraction of metal W was at 10%-30% bimetallic heterogeneous catalyst. Moreover, the results of XRD characterization and TEM characterization (pattern not shown) are similar to those of Example 1 above.

Embodiment 3

[0055] With the same preparation and characterization procedures as Example 1 and / or according to the aforementioned general method, except using H 2 PtCl 6 and Ce(NH 4 ) 2 (NO 3 ) 6 And change the dosage and the type and dosage of the carrier to prepare the bimetallic heterogeneous catalyst with the mass fraction of metal Pt at 0.5%-10% and the mass fraction of metal Ce at 10%-30% as shown in Table 1. Moreover, the results of XRD characterization and TEM characterization (pattern not shown) are similar to those of Example 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com