Pt-Ni alloy nanomaterial adopting network structure and preparation method thereof

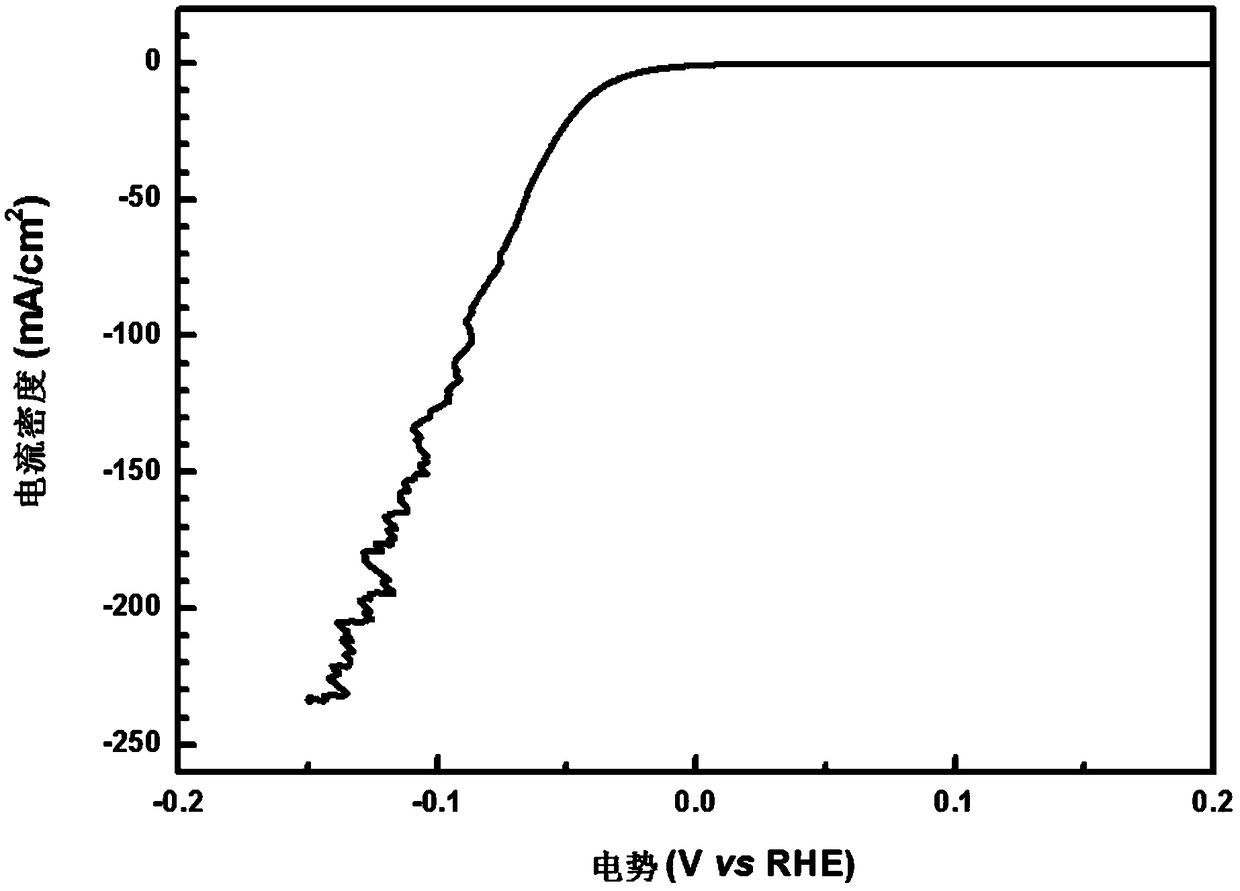

A technology of alloy nanomaterials and network structures, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrodes, etc., can solve the complex preparation process of Pt-based alloy nanomaterials Low porosity, unfavorable for large-scale preparation of catalysts, etc., achieve good promotion and application prospects, simple and feasible preparation process, and improve catalytic activity and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

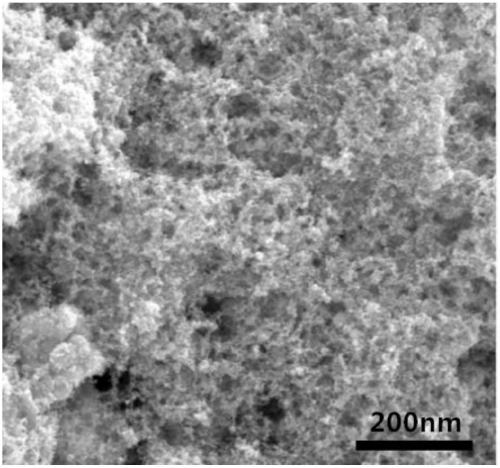

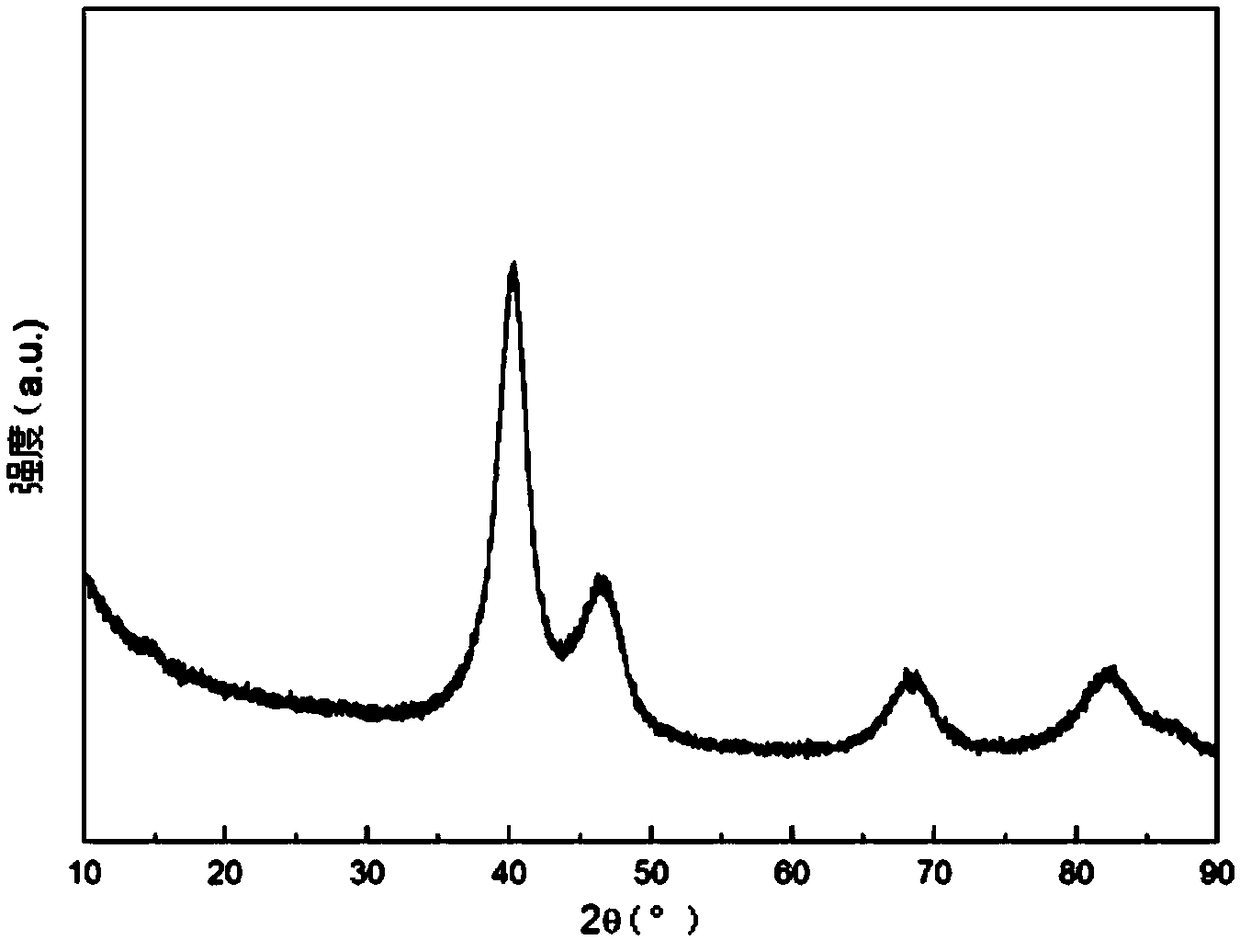

[0016] Specific embodiment 1: The network structure Pt-Ni alloy nanomaterial in this embodiment is a spongy three-dimensional network structure formed by interconnecting Pt-Ni alloy nanoparticles; the particle size of a single Pt-Ni alloy nanoparticle The diameter is 20nm~30nm; the porosity of the network structure Pt-Ni alloy nanomaterial is 50%~70%, and the specific surface area of the network structure Pt-Ni alloy nanomaterial calculated according to the mass of Pt is 35m 2 / g~50m 2 / g.

specific Embodiment approach 2

[0017] Specific embodiment two: the preparation method of a kind of network structure Pt-Ni alloy nano material of present embodiment is carried out according to the following steps:

[0018] 1. First, mix cetyltrimethylammonium bromide, chloroform, ultrapure water and isopropanol, and stir for 30 minutes to 120 minutes at room temperature and at a stirring speed of 50 rpm to 100 rpm to obtain sol micelles, and then Add chloroplatinic acid and nickel acetate to the sol micelles in turn, and continue stirring for 1h to 2h under the condition of a stirring speed of 50rpm to 100rpm to obtain a mixed solution;

[0019] The mole of described cetyl trimethyl ammonium bromide and the volume ratio of chloroform are 1mmol:(10~100) mL; The mole of described cetyl trimethyl ammonium bromide and the volume ratio of ultrapure water The volume ratio is 1mmol: (5~20) mL; the volume ratio of the mole of the cetyltrimethylammonium bromide to isopropanol is 1mmol: (15~45) mL; the cetyl The mol...

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step 2, the mixed solution is placed 60 Co gamma ray is irradiated, under the condition that the total dose is 10kGy-20kGy, irradiated for 5h-10h, and the solution after irradiation is obtained. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com