Induction welding equipment and method for thermoplastic resin matrix composite with internal electromagnetic material

A thermoplastic resin and composite material technology, applied in the fields of manufacturing and material forming, can solve the problems of reducing joint strength and fatigue performance, limiting the shape and size of the object to be welded, affecting welding quality, etc., so as to reduce magnetic flux leakage and reduce welding stress. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

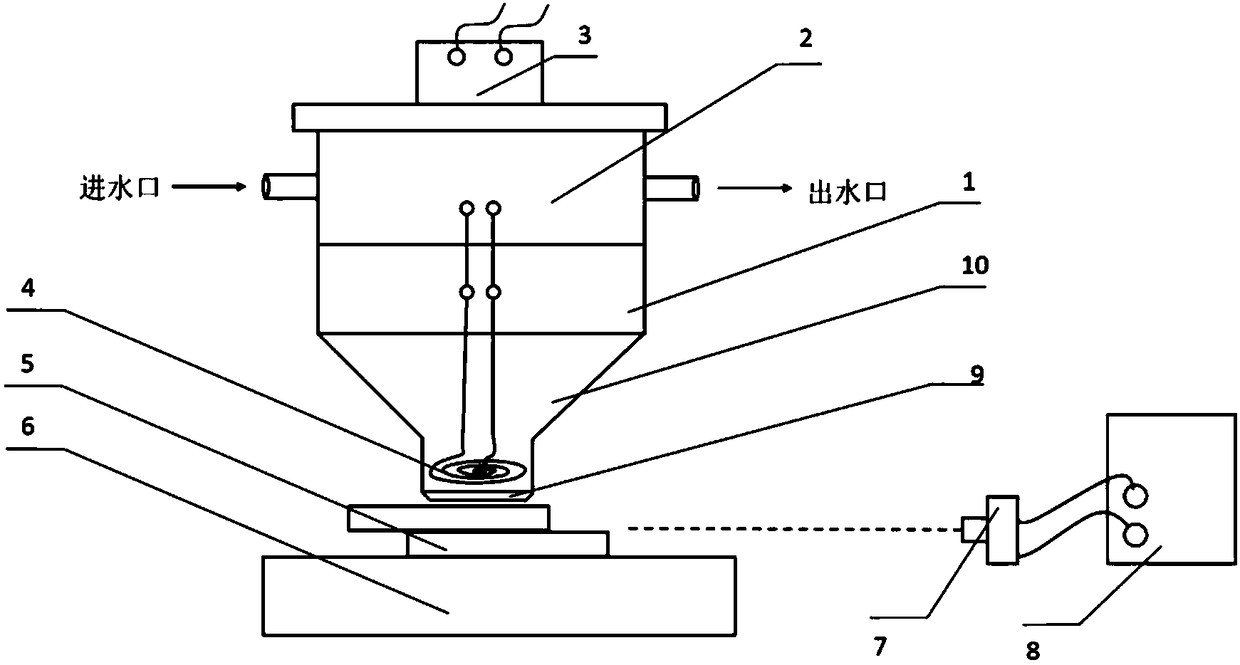

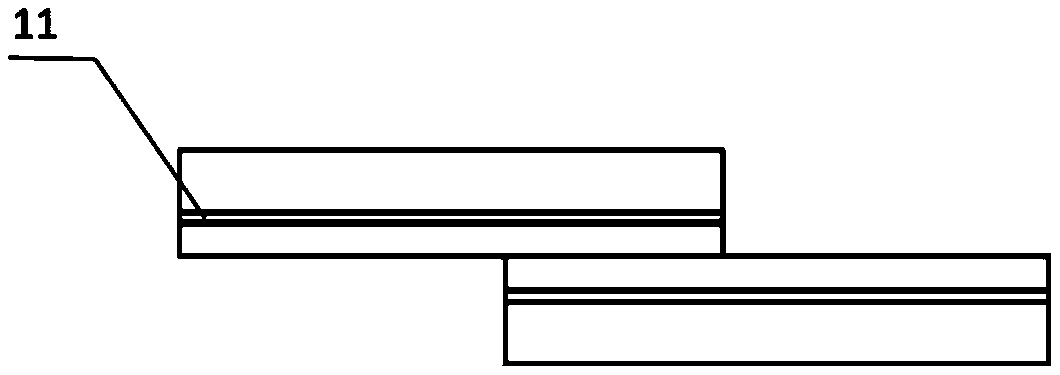

[0029] Embodiment 1: see figure 1 and figure 2 , the thermoplastic resin-based composite material induction welding equipment with built-in electromagnetic material of the present embodiment, comprises induction generator 1, and it is the high-frequency (2-10MHz) power supply that can convert the power supply of 40Hz-70Hz into power generally 1-5KW , the press 3 provides a pre-pressure of 0.45-1.20MPa, which is the pressure head connected to the cylinder or the liquid cylinder; the induction coil 4 and the heat exchanger 2 connected to it, the induction coil 4 can be a single-turn coil, a multi-turn coil, a disk In the form of coil coils, hairpin coils, etc., can be made of copper tube, sheet or machined block, the induction coil is water cooled. Coils can be square, round or rectangular, and the common sizes are 3.2mm, 4.8mm, 6.4mm, 9.5mm. The induction coil 4 is a hollow coil, connected to the heat exchanger 2 for circulating water cooling, the heat insulation plate 9 and...

Embodiment 2

[0030] Example 2: see figure 1 and 2 , an induction welding method based on the induction welding equipment described in the above-mentioned embodiment 1, specifically placing the composite material welded piece 5 on the backing plate 6, and applying a pre-pressure of 0.45-1.20 MPa to the composite material to be welded by the pressurizing device 3 , and then connect the induction generator 1, the induction generator 1 can convert the 40Hz-70Hz power supply into a high-frequency (2-10MHz) power supply device with a power of 1-5KW, and then give the induction coil a high frequency of 2-10MHz, Generate an electromagnetic field capable of heating the built-in conductive magnetic material 11, and sequentially heat and melt the surrounding thermoplastic resin-based composite material through heat conduction. Since the induction coil 4 is a hollow structure, the heat exchanger 2 can be used to feed into it while the induction coil is working. Circulating water, under the cooling ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com