Si/SiO2/C composite nanofiber material, preparation method thereof and anode material

A technology of composite nanofibers and carbon nanofibers, applied in the direction of negative electrodes, nanotechnology, nanotechnology, etc., can solve the problems of affecting battery cycle stability, detachment and cracking of carbon coating layers, poor structural stability of silicon-carbon composite materials, etc. , to achieve the effect of excellent cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In a second aspect, the present invention provides a Si / SiO 2 The preparation method of / C composite nanofiber material comprises the following steps:

[0047] Available with Si / SiO 2 The electrospinning dispersion of particles, after electrospinning and carbonization treatment, the Si / SiO 2 / C composite nanofiber material.

[0048] Electrospinning method on Si / SiO 2 Particles coated with carbon nanofibers can be realized on Si / SiO 2 Growth of carbon nanofibers on the particle surface improves the Si / SiO 2 The bonding strength between particles and carbon nanofibers, thereby improving the Si / SiO 2 Structural stability of / C composite nanofibrous materials.

[0049] In some embodiments of the present invention, the preparation method of the electrospinning dispersion comprises the following steps:

[0050] a) Preparation of Si / SiO 2 Particles: Provide a mixed aqueous solution containing lithium salt and complexing agent, add Si particles to the mixed aqueous solu...

Embodiment 1

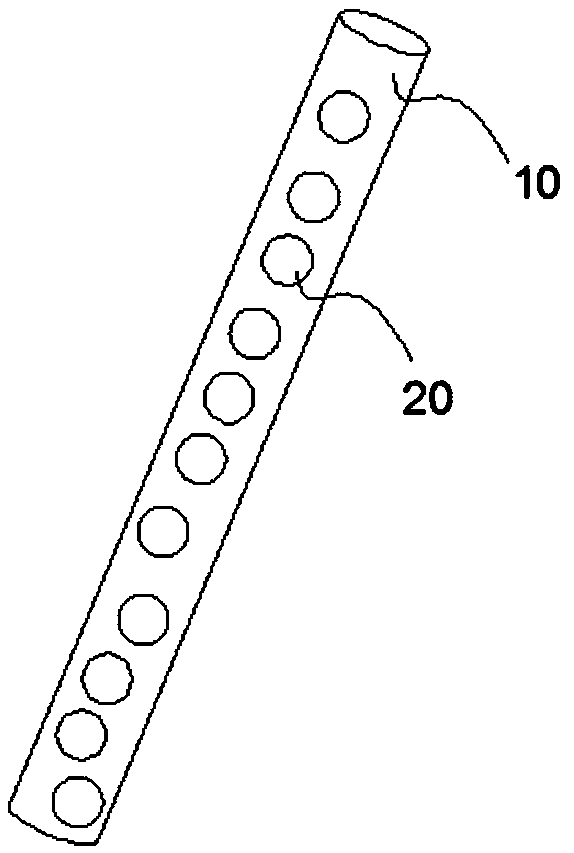

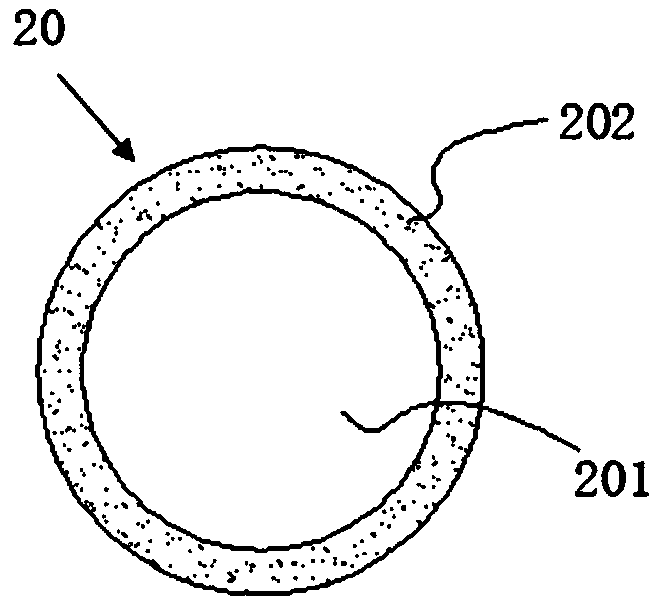

[0096] This embodiment is a Si / SiO 2 / C composite nanofiber materials, such as figure 1 with 2 As shown, including: carbon nanofibers 10 and Si / SiO located inside the carbon nanofibers 10 2 Particle 20, Si / SiO 2 Particle 20 is a core-shell structure, including Si particle 201 and SiO coated Si particle 2 cladding layer 202 .

[0097] The Si / SiO 2 / C composite nanofiber material preparation method is as follows:

[0098] A) Configure 600mL of polyvinylpyrrolidone (PVP) absolute ethanol solution at a mass fraction of 12%, and stir at 25°C for 12h to obtain an electrospinning solution;

[0099] B) Add 1.97g of lithium hydroxide, 15.8g of citric acid and 5.72g of nano-Si into an appropriate amount of deionized water and stir evenly. Stir at 50°C for 2h to make a gel, dry the gel at 70°C for 12h, and grind Obtain solid powder after crushing;

[0100] C) Put the solid powder into a muffle furnace, raise the temperature to 400°C at a heating rate of 3°C / min and keep it for 2h...

Embodiment 2

[0104] This embodiment is a Si / SiO 2 / C composite nanofibrous material, its structure is the same as that in Example 1, the Si / SiO 2 The preparation method of / C composite nanofiber material is as follows:

[0105]A) 600 mL of deionized aqueous solution of polyvinyl alcohol (PVA) was configured according to a mass fraction of 10%, and stirred at 95° C. for 10 h to obtain an electrospinning solution;

[0106] B) Add 5g of lithium carbonate, 21.7g of sodium carboxymethylcellulose and 9.43g of nano-Si into an appropriate amount of deionized water and stir evenly, stir at 60°C for 3h to make a gel, and dry the gel at 80°C for 10h , to obtain solid powder after grinding and crushing;

[0107] C) Put the solid powder into a muffle furnace, raise the temperature to 450°C at a heating rate of 2°C / min and keep it for 1h to prepare Si / Li 4 SiO 4 Particles; the Si / Li 4 SiO 4 The particles were added to an appropriate amount of deionized water, heated to 96°C and stirred for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com