Low-water-consumption wet desulphurization method

A technology of wet desulfurization and low water consumption, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of immaturity, technology and equipment, etc., and achieve the effect of reducing processing costs and reducing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

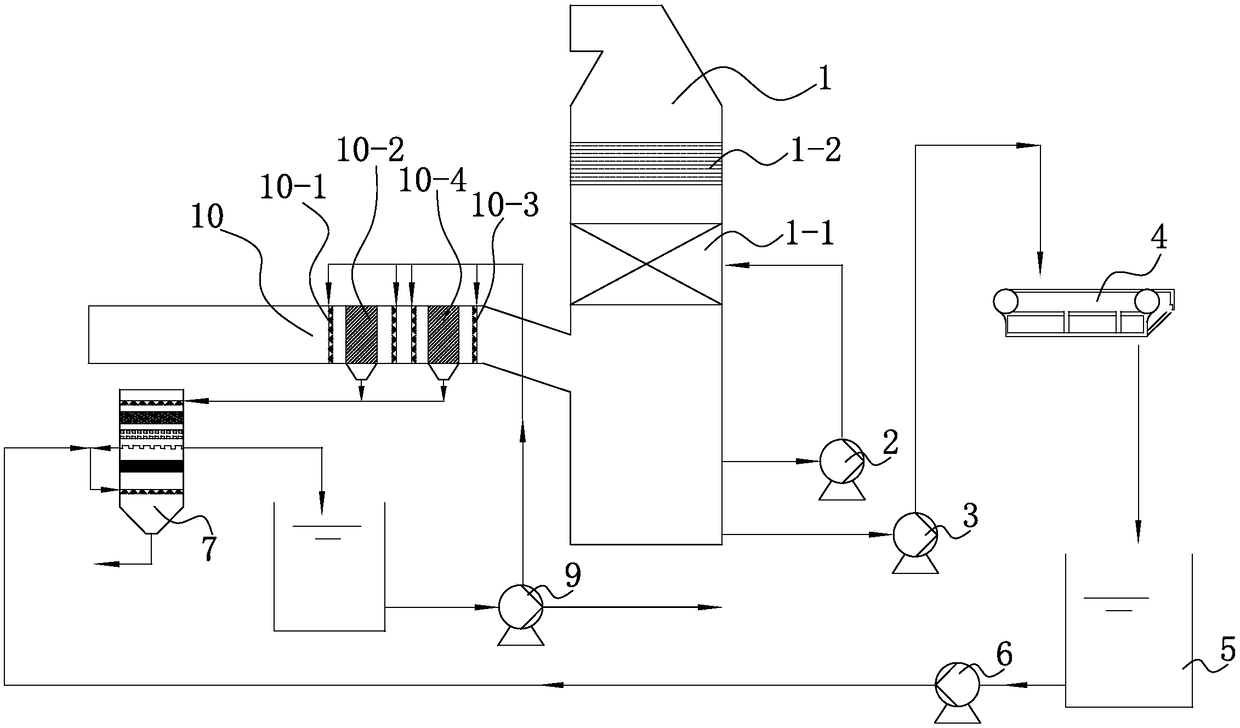

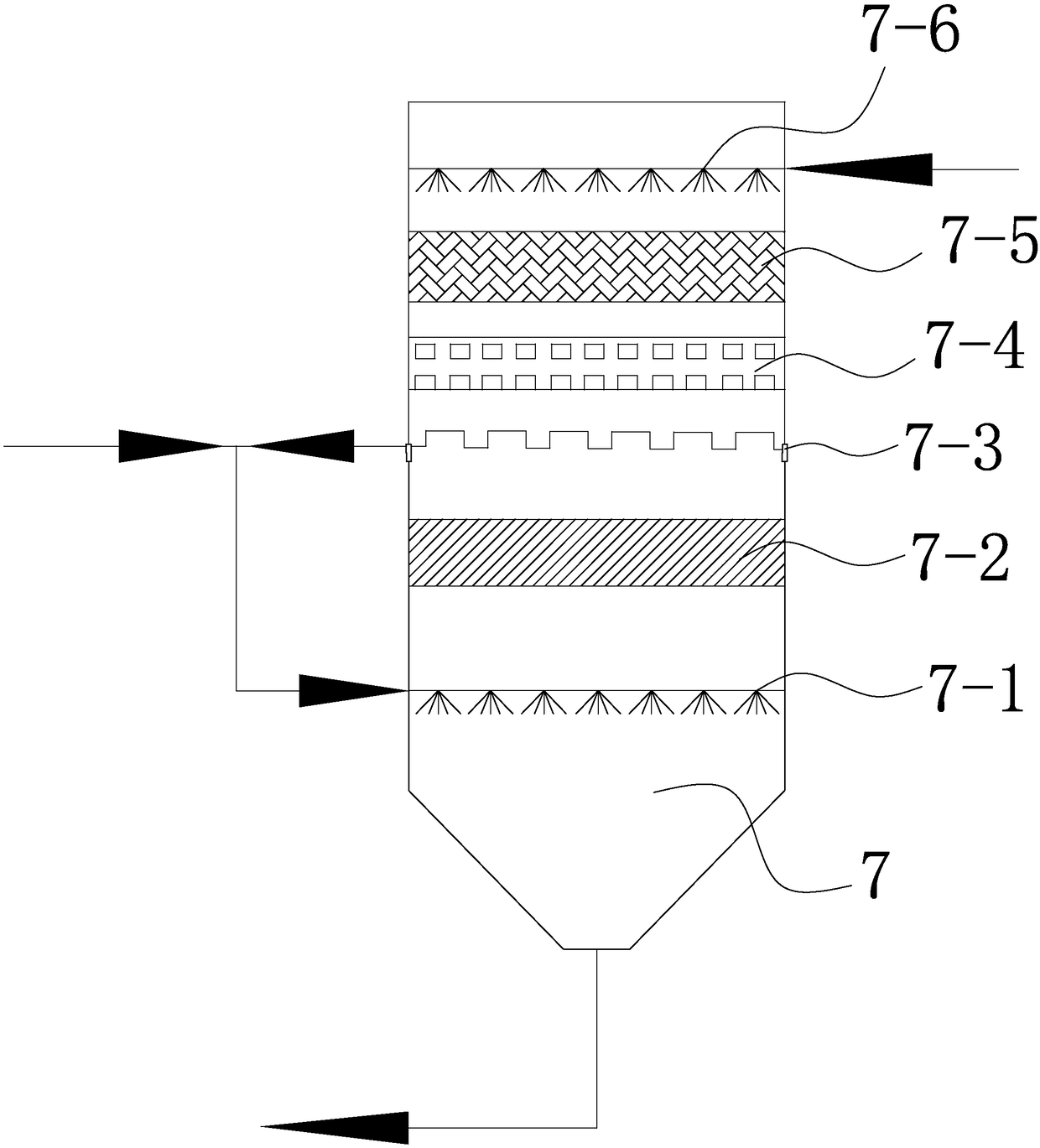

Embodiment 1

[0040] The flue gas desulfurization renovation project of a 300WM coal-fired unit adopts this process, and the SO in the inlet flue gas 2 The concentration is 2239mg / m 3 , the dust concentration in the inlet flue gas is 43mg / m 3 ; Humidification and cooling device 10 waste water spraying layer 10-1, 10-3 set 4 layers, the liquid-gas ratio is 3.6L / Nm 3 ; Inlet flue demister layers 10-2, 10-4 are provided with 2 layers with a width of 0.40m, and the distance between wastewater spray layers 10-1, 10-3 and demister layers 10-2, 10-4 is 0.8 m; The liquid-gas ratio of the 10-1 and 10-3 circulating liquid in the wastewater spray layer is 14L / Nm 3 , the coverage rate of wastewater spray layer 10-1 and 10-3 is 300%, the pH of desulfurization slurry is 5.30; The vertical flow velocity of wastewater in the chamber is 0.30mm / s; the SO in the outlet flue gas 2 The concentration is 12.4mg / m 3 , the dust concentration in the outlet flue gas is 2.6mg / m 3 , the purity of desulfurization ...

Embodiment 2

[0042] The flue gas desulfurization renovation project of a 300WM coal-fired unit adopts this process, and the SO in the inlet flue gas 2 The concentration is 2239mg / m 3 , the dust concentration in the inlet flue gas is 43mg / m3 ; Humidifying and cooling device 10 waste water spraying layer 10-1, 10-3 is provided with 2 layers, and the liquid-gas ratio is 3.0L / Nm 3 ; Inlet flue demister layers 10-2, 10-4 are provided with 2 layers with a width of 0.20m, and the distance between wastewater spray layers 10-1, 10-3 and demister layers 10-2, 10-4 is 0.5 m; the liquid-gas ratio of the 10-1 and 10-3 circulating liquid in the wastewater spray layer is 10L / Nm 3 , the coverage rate of wastewater spray layer 10-1 and 10-3 is 300%, the pH of desulfurization slurry is 5.30; The vertical flow velocity of wastewater in the chamber is 0.30mm / s; the SO in the outlet flue gas 2 The concentration is 12.4mg / m 3 , the dust concentration in the outlet flue gas is 2.6mg / m 3 , the purity of desu...

Embodiment 3

[0044] The flue gas desulfurization renovation project of a 300WM coal-fired unit adopts this process, and the SO in the inlet flue gas 2 The concentration is 2239mg / m 3 , the dust concentration in the inlet flue gas is 43mg / m 3 ; Humidifying and cooling device 10 waste water spraying layer 10-1, 10-3 is provided with 2 layers, and the liquid-gas ratio is 2.0L / Nm 3 ; Inlet flue demister layers 10-2, 10-4 are provided with 2 layers with a width of 0.20m, and the distance between wastewater spray layers 10-1, 10-3 and demister layers 10-2, 10-4 is 0.5 m; the liquid-gas ratio of the 10-1 and 10-3 circulating liquid in the wastewater spray layer is 10L / Nm 3 , the coverage rate of wastewater spray layer 10-1 and 10-3 is 200%, the pH of desulfurization slurry is 5.30; The vertical flow velocity of wastewater in the chamber is 0.30mm / s; the SO in the outlet flue gas 2 The concentration is 12.4mg / m 3 , the dust concentration in the outlet flue gas is 2.6mg / m 3 , the purity of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com