Contaminated soil repairing device and method by adopting temperature control electric coupling spraying method

A rinsing device and technology for polluted soil are applied in the field of temperature-controlled electric coupling rinsing method to repair polluted soil devices, which can solve the problem of low efficiency, and achieve the effects of accelerating migration, improving the efficiency of electric repairing, and improving the effect of electromigration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment one, device

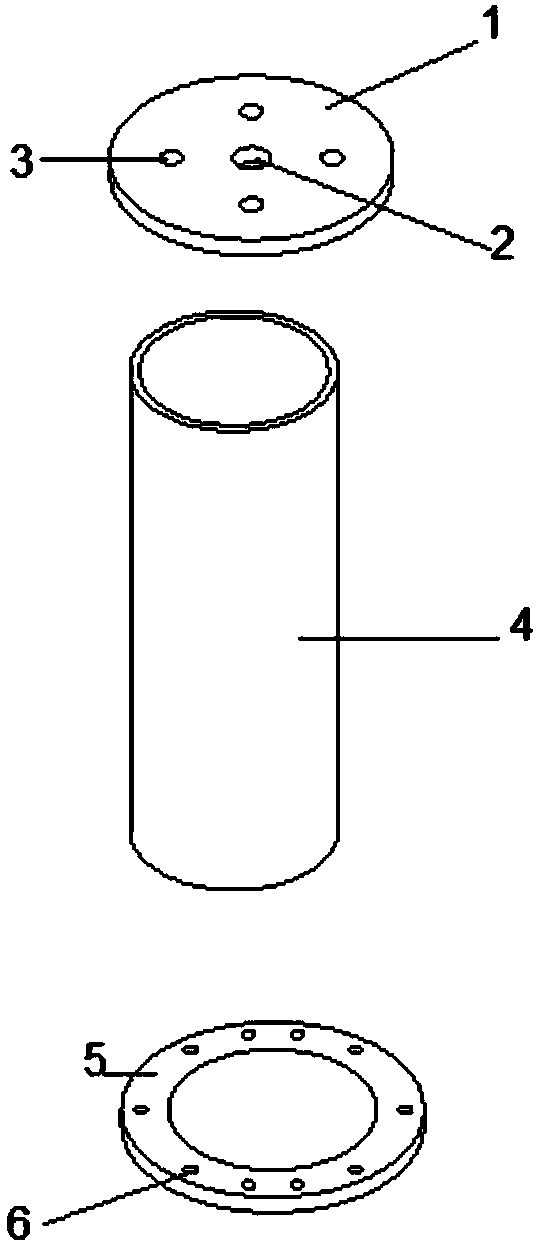

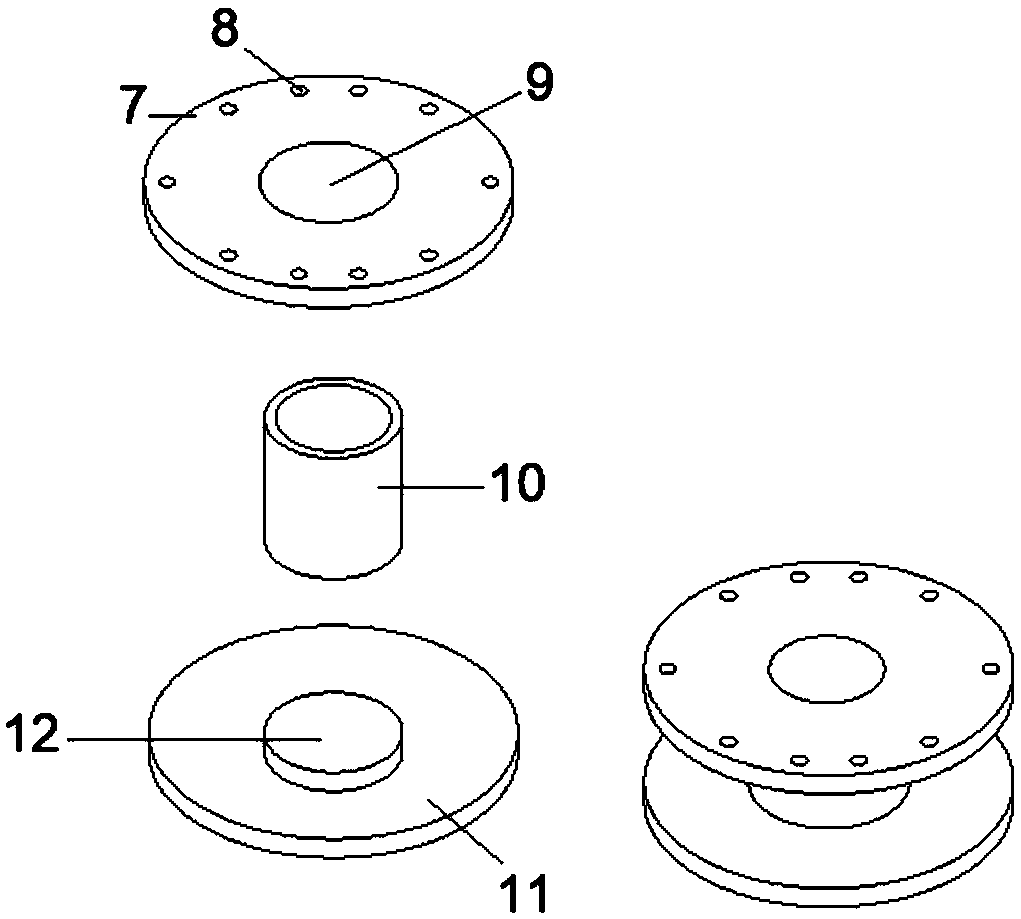

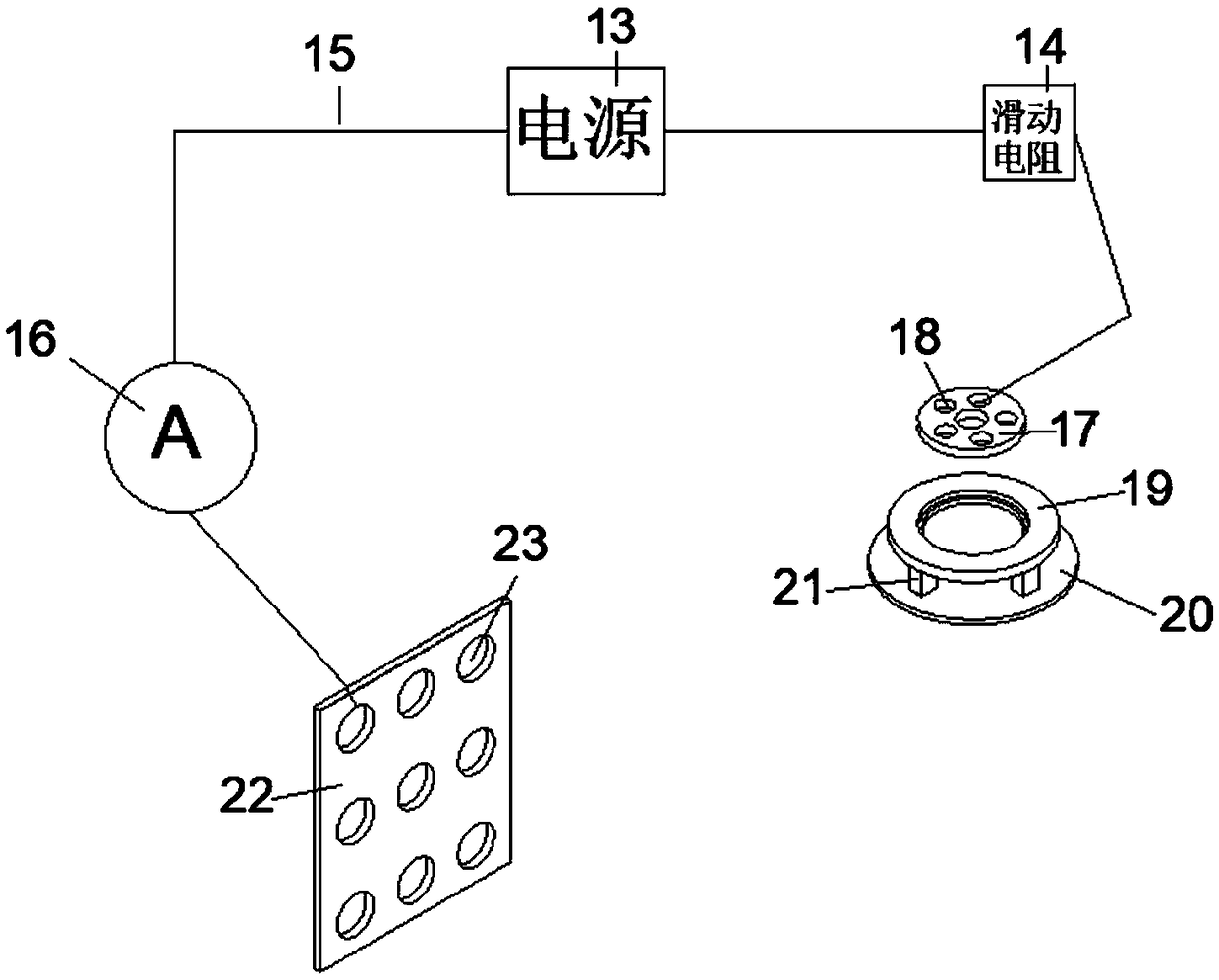

[0051] In this example, if figure 1 As shown, a plexiglass plate and a plexiglass tube are used to make a washing device, and the plexiglass sheet is cut by a table saw, an engraving machine, etc. to make an upper plexiglass cover slip 1 with a diameter of 160 mm and a thickness of 2 mm. 1. Make a reserved electric heating rod thermocouple insertion hole 2 with a diameter of 25mm in the center, and evenly punch 4 upper exhaust holes 40mm from the edge of the upper organic glass cover sheet 1. 3; make a diameter of 160mm by cutting a organic glass plate Hollow organic glass sheet 5 in the lower part, open a hole with a diameter of 100mm at the center of the hollow organic glass sheet 5 in the lower part, and evenly punch 10 bolt holes 6 reserved for the hollow organic glass sheet in the lower part at 10 mm from the outer edge of the hollow organic glass sheet 5 in the lower part; Make the middle plexiglass tube 4 with an outer diameter of 100 mm...

Embodiment 2

[0062] Embodiment two, processing method

[0063] In this embodiment, the soil treatment chamber is placed on the supporting device, and a permeable stone is placed at the bottom of the soil treatment chamber; 200 g of heavy metal contaminated soil is put into the soil treatment chamber and compacted; Place a circular hollow PVC liner plate 25 between them, and connect with a nut 28 with a bolt 24 to seal; put the heat preservation pipe sleeve 45 on the middle plexiglass tube 4 of the rinsing device, and put the plastic square frame 36 of the electrolyte collecting device Put in the square thermal insulation foam box 44; Configure the anolyte solution 6000g, and put it into the electrolyte collection device, configure the catholyte solution 2000g, and put it into the rinsing device; put the superstructure (comprising the rinsing device, soil treatment room, supporting device, etc.) into the electrolyte collection device; place the stainless steel electrode plate 22 on one side...

Embodiment 3

[0066] Example 3. Research on the effect of electrodynamic restoration of certain hexavalent chromium-contaminated soil at a temperature of 45°C, a voltage of 30V, a solution of 0.5% KCL and 0.5% citric acid as the cathodic eluent, and a electrodynamic restoration time of 2 days.

[0067] In this embodiment, the specific steps are as follows:

[0068] (1) Take 200g of hexavalent chromium-contaminated soil.

[0069] (2) Sampling the soil, marking the chromium concentration as a, packing the soil sample with a sampling bag and sealing it up.

[0070] (3) Prepare a solution of 2000 g of 0.5% KCL and 0.5% citric acid.

[0071] (4) Install the temperature-controlled electric coupling leaching method to restore the contaminated soil device.

[0072] (5) Turn on the power, adjust the sliding rheostat to a current of 30mA, and carry out the experiment.

[0073] (6) Turn off the power after 2 days, take out the polluted soil soil sample, divide the soil sample into 5 parts b, c, d, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com