Preparation method for regulating spherical nano silicon particles and spherical mesoporous nano silicon particles

A nano-silicon and spherical technology, which is applied in the field of preparation of spherical nano-silicon particles and spherical mesoporous nano-silicon particles, to achieve uniform particle size distribution, uniform pore structure, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

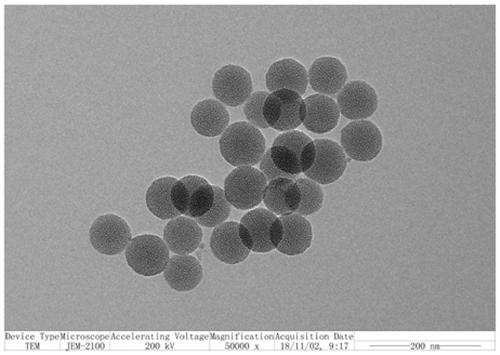

[0036] Add 1.5 g of cetyltrimethylammonium bromide and 0.17 g of sodium acetate (1:0.5 molar ratio) into 100 ml of deionized water, stir and dissolve at 95 °C for 30 minutes, add 2 ml of ethyl orthosilicate Stir the reaction for 2 hours, centrifuge at 12000 rpm for 20 minutes, discard the supernatant; disperse and centrifuge with 20 ml of water or ethanol, repeat washing 2-3 times, and dry to obtain spherical mesoporous silicon with a particle size of 76±5 nm Nano silicon particles ( figure 1 ).

Embodiment 2

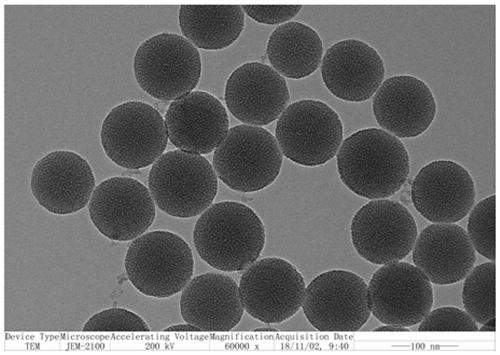

[0038] Add 1.5 grams of cetyltrimethylammonium bromide and 0.17 grams of sodium acetate (molar ratio: 1:0.5) into 100 milliliters of deionized water, stir and dissolve at 95 ° C for 30 minutes, add 4 milliliters of ethyl orthosilicate Stir the reaction for 2 hours, centrifuge at 12000 rpm for 20 minutes, discard the supernatant; disperse and centrifuge with 20 ml of water or ethanol, wash repeatedly 2-3 times, and dry to obtain a spherical mesoporous nanometer with a particle size of 97±4 nanometers. Silicon particles ( figure 2 ).

Embodiment 3

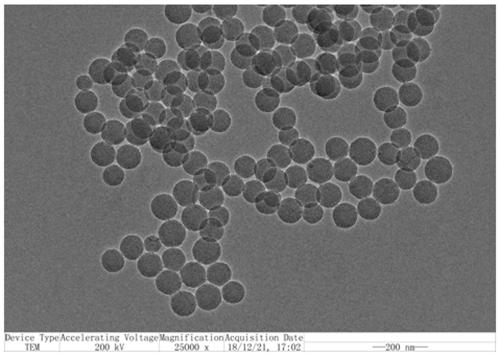

[0040] Add 1.5 g of cetyltrimethylammonium bromide and 0.23 g of sodium butyrate (molar ratio 1:0.5) into 100 ml of deionized water, stir and dissolve at 95°C for 30 minutes, add 2 ml of ethyl orthosilicate Stir the reaction for 2 hours, centrifuge at 12000 rpm for 20 minutes, discard the supernatant; disperse and centrifuge with 20 ml of water or ethanol, and wash repeatedly 2-3 times to obtain spherical mesoporous nano-silicon particles with a particle size of 89±5 nm ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com