Foam glass ceramic composite building thermal insulation material and preparation method thereof

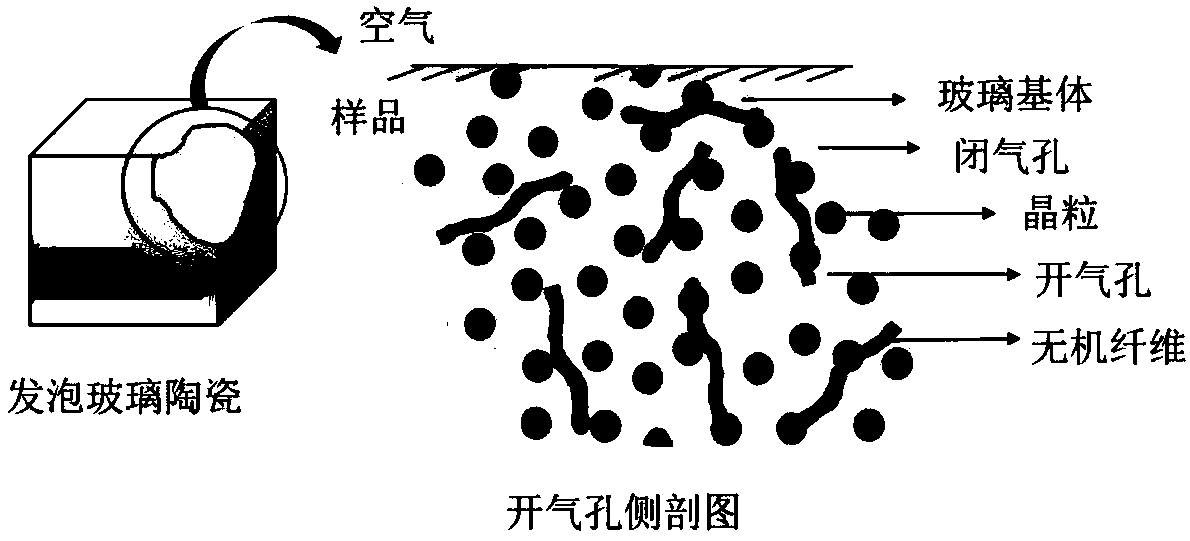

A technology of ceramic composite and building insulation, applied in the field of building materials, can solve the problems of difficult industrial transformation, complex firing process and high cost of raw materials, etc., to achieve improved stability and mechanical properties, good respiratory and humidity control performance, mechanical good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

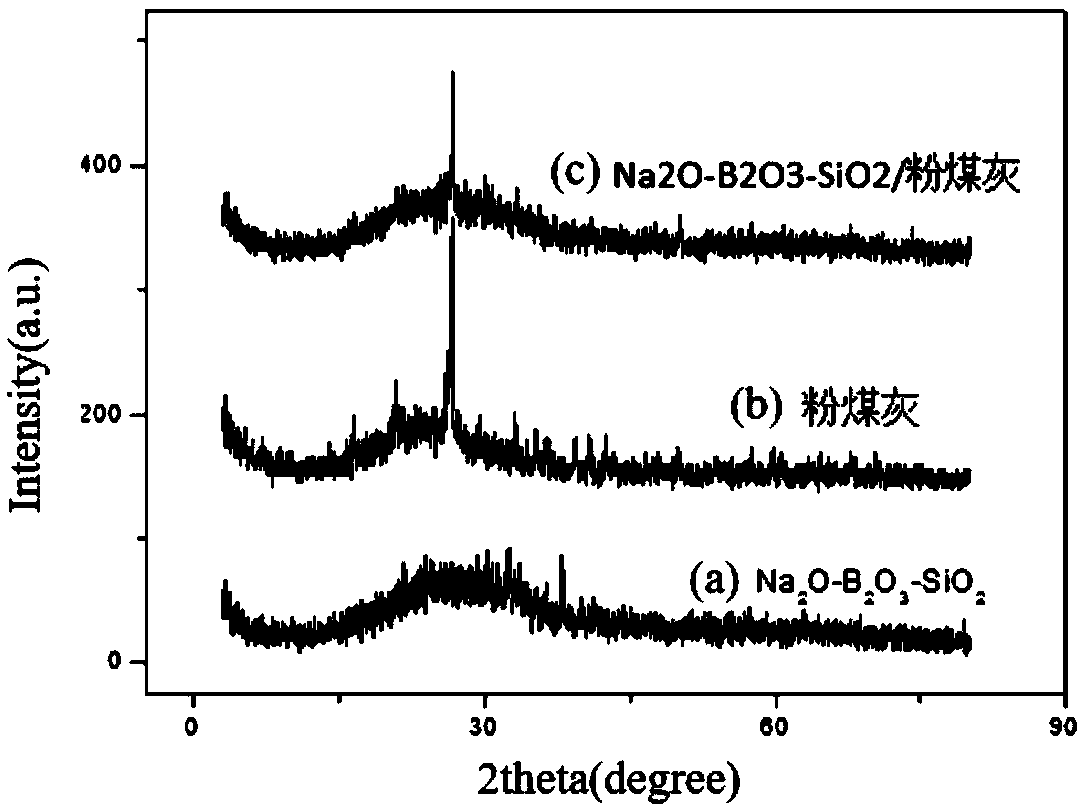

[0046] The test was carried out with liquid sodium silicate water glass with a modulus of 2.4 and a solid content of 48.95%, boric acid, fly ash (particle diameter about 25 μm), and glass fiber (diameter 16 μm, length 6 mm). The specific raw material proportions and main component mass fractions in formulas 1, 2, and 3 are shown in the table below.

[0047]

[0048] (Remarks: Because the amount of glass fiber is too low, the content of each chemical component is low, so it is not reflected in the table, the same below)

[0049] The raw materials of each formula were sheared at a high speed of 4000r / min for 30 minutes, dispersed and mixed evenly, and mixed sols of different viscosities were obtained without gelling; the sols of different formulas were poured into ceramic molds and moved into high-temperature furnaces; According to the heating rate of 3°C / min, it is heated from room temperature to 400°C and held for 0.5h, and then placed directly in the furnace at 500°C, and ...

Embodiment 2

[0061] The test was carried out with liquid sodium silicate water glass with a modulus of 2.4 and a solid content of 48.95%, boric acid, fly ash (particle diameter about 25 μm), and glass fiber (diameter 16 μm, length 6 mm). The specific raw material proportions and main component mass fractions in formulas 1, 2, 3, and 4 are shown in the table below.

[0062]

[0063] The raw materials of each formula were sheared at a high speed of 4000r / min for 30 minutes and dispersed and mixed evenly to obtain mixed sols of different viscosities without gelling; pour the sols of different proportions into ceramic molds and move them into a high-temperature furnace Heating from room temperature to 400°C at a heating rate of 3°C / min and keeping it warm for 0.5h, then placing it directly in a furnace at 500°C and keeping it warm for 1-4h to obtain foam glass ceramics with different hydroxyl content.

[0064] The foamed glass-ceramics obtained according to formula 1-3 are subjected to rele...

Embodiment 3

[0075] The test was carried out with liquid sodium silicate water glass with a modulus of 2.8 and a solid content of 36%, boric acid, fly ash (particle diameter about 25 μm), and glass fiber (diameter 16 μm, length 6 mm). The specific raw material proportions and main component mass fractions in formulas 1, 2, 3, and 4 are shown in the table below.

[0076]

[0077]

[0078] The raw materials of each formula were sheared at a high speed of 4000r / min for 30 minutes and dispersed and mixed evenly to obtain mixed sols of different viscosities without gelling; pour the sols of different proportions into ceramic molds and move them into a high-temperature furnace Heating from room temperature to 400°C at a heating rate of 3°C / min and keeping it warm for 0.5h, then placing it directly in a furnace at 500°C and keeping it warm for 1-4h to obtain foam glass ceramics with different hydroxyl content.

[0079] The foamed glass-ceramics obtained according to formula 1-4 are subjecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com