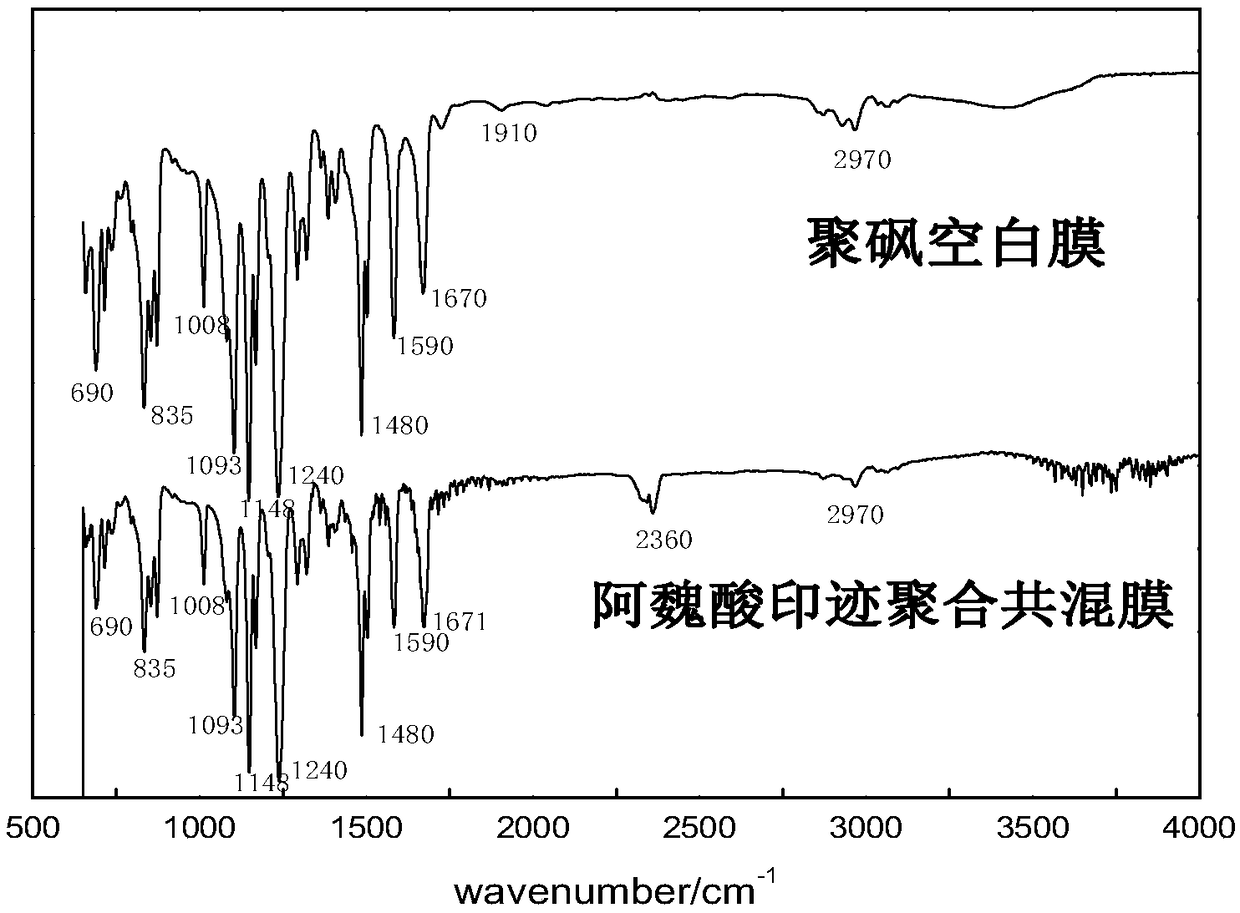

Preparation method of ferulic acid molecularly imprinted blend membrane material

A technology of molecular imprinting and ferulic acid, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of easy agglomeration, the influence of organic film strength and toughness, small particle size of nanoparticles, etc., and achieves simple and easy preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] (1) Dissolve 0.0486g of ferulic acid and 0.0355g of acrylamide in acetonitrile and stir. After fully shaking, put it in the refrigerator and let it stand for 9-12h.

[0032] (2) Take the solution in step (1) out of the refrigerator, add 36.6mg of azobisisobutyronitrile and 1.24g of ethylene glycol dimethacrylate, then pass nitrogen gas for several minutes, and keep the temperature in a water bath at 60°C After heating for 24 hours, a large amount of white precipitates, namely ferulic acid molecularly imprinted microspheres, were obtained.

[0033] (3) The polymer microspheres in the step (2) are suction-filtered, and washed repeatedly with a mixed solution of methanol and acetic acid until no ferulic acid is detected.

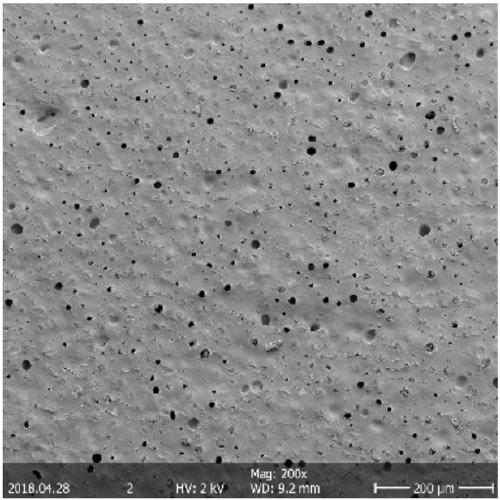

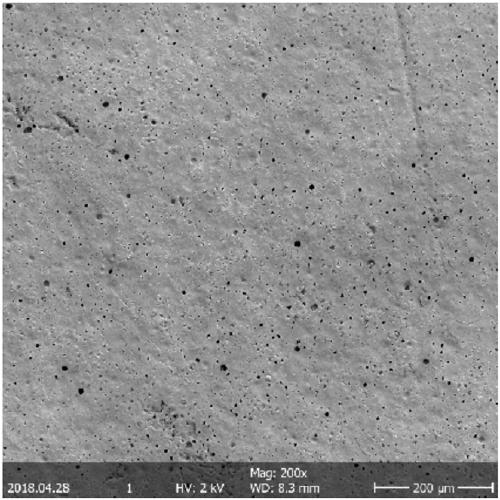

[0034] (4) Weigh 4.95g of polysulfone and 0.05g of ferulic acid molecularly imprinted polymer microspheres, add 20ml of N,N-dimethylformamide, stir and heat at 65°C until the polysulfone (PSF) is co...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] (1) Dissolve 0.0484g of ferulic acid and 0.0533g of acrylamide in acetonitrile and stir. After fully shaking, put it in the refrigerator and let it stand for 9-12h.

[0039] (2) Take the solution in (1) out of the refrigerator, add 36.6mg of azobisisobutyronitrile and 1.24g of ethylene glycol dimethacrylate, then pass nitrogen gas for several minutes, and heat in a water bath at a constant temperature of 60°C for 24h , to obtain a large amount of white precipitate, that is, ferulic acid molecularly imprinted microspheres.

[0040](3) The polymer microspheres in (2) are suction-filtered, and washed repeatedly with a mixed solution of methanol and acetic acid until no ferulic acid is detected.

[0041] (4) Weigh 4.85g of polysulfone and 0.15g of ferulic acid molecularly imprinted polymer microspheres, add 25ml of N,N-dimethylformamide, stir and heat at 65°C until the polysulfone (PSF) is completely dissolved, Put th...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] (1) Dissolve 0.0486g of ferulic acid and 0.0711g of acrylamide in acetonitrile and stir. After fully shaking, put it in the refrigerator and let it stand for 9-12h.

[0046] (2) Take the solution in (1) out of the refrigerator, add 36.6mg of azobisisobutyronitrile and 1.24g of ethylene glycol dimethacrylate, then pass nitrogen gas for several minutes, and heat in a water bath at a constant temperature of 60°C for 24h , to obtain a large amount of white precipitate, that is, ferulic acid molecularly imprinted microspheres.

[0047] (3) The polymer microspheres in (2) are suction-filtered, and washed repeatedly with a mixed solution of methanol and acetic acid until no ferulic acid is detected.

[0048] (4) Weigh 4.75g of polysulfone and 0.25g of ferulic acid molecularly imprinted polymer microspheres, add 25ml of N,N-dimethylformamide, stir and heat at 65°C until the polysulfone (PSF) is completely dissolved, Put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com