Method for manufacturing degradable packaging film by tamarind seeds

A technology of packaging film and tamarind powder, which is applied in the field of food engineering, can solve the problems of unresearched film-forming process, low utilization rate, research on retention extraction process, etc., and achieve excellent antibacterial performance, low cost, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

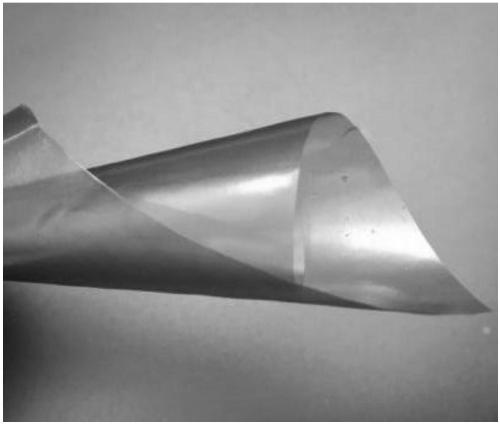

Image

Examples

Embodiment 1

[0029] A method of making degradable packaging film with tamarind seeds, comprising the following steps:

[0030] (1) Select the sweet-type small-curved fruit, remove the pulp and wash to obtain tamarind seeds, dry them at 50°C for 5 hours, then place them in a traditional Chinese medicine grinder for crushing, and pass through a 50-mesh sieve to obtain tamarind powder for later use ;

[0031] (2) Mix the tamarind seed powder obtained in step (1) with water according to a material-to-liquid ratio of 1:45g / mL, and heat the mixture to boiling for 40 minutes until the powder is completely dissolved, during which the lost moisture is constantly replenished;

[0032] (3) Step (2) is processed, and after the feed liquid is cooled, filter it with a 250-mesh filter bag, take the clear liquid, add 0.3% glycerin thereto, homogeneously degas, cast the film into a film, and obtain the finished product. The operation of the degassing treatment is to store the gas in the film-forming liqui...

Embodiment 2

[0037] A method of making degradable packaging film with tamarind seeds, comprising the following steps:

[0038] (1) Select the sweet-type small-curved fruit, remove the pulp and wash to obtain tamarind seeds, dry them at 80°C for 3 hours, then place them in a traditional Chinese medicine grinder for crushing, and pass through a 80-mesh sieve to obtain tamarind powder for later use ;

[0039] (2) Mix the tamarind seed powder obtained in step (1) with water according to the ratio of material to liquid of 1:60g / mL, heat the mixture to boiling for 55min until the powder is completely dissolved, and constantly replenish the lost moisture during the period;

[0040] (3) Step (2) is processed, and after the feed liquid is cooled, filter it with a 350-mesh filter bag, take the clear liquid, add 0.6% glycerin thereto, homogeneously degas, cast the film into a film, and obtain the finished product. The operation of the degassing treatment is to store the gas in the film-forming liqui...

Embodiment 3

[0045] A method of making degradable packaging film with tamarind seeds, comprising the following steps:

[0046] (1) Select the sweet small curved fruit, remove the pulp and wash to obtain tamarind seeds, dry at 65°C for 4 hours, then put them in a traditional Chinese medicine grinder and grind them, and pass through a 60-mesh sieve to obtain tamarind powder for later use ;

[0047](2) mixing tamarind seed powder obtained in step (1) with water according to the ratio of material to liquid is 1:50g / mL, heating the mixture to boiling for 50min until the powder is completely dissolved, during which the lost moisture is constantly replenished;

[0048] (3) Step (2) is processed, and after the feed liquid is cooled, filter it with a 300-mesh filter bag, take the clear liquid, add 0.5% glycerin therein, homogeneously degas, and form a film by casting method to obtain the finished product. The operation of the degassing treatment is: store the gas in the film-forming liquid for 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com