A kind of thixotropic water-based modified asphalt waterproof coating and preparation method thereof

A bituminous waterproof coating, water-based modification technology, applied in the direction of asphalt coating, chloroprene homopolymer coating, coating, etc., can solve the problems of construction restrictions, affecting the adhesion performance of the coating film, affecting the application effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The thixotropic water-based modified asphalt waterproof coating consists of the following components by weight: 28 parts of anionic emulsified asphalt, 9 parts of neoprene latex, 29 parts of water, 30 parts of quartz sand, and 0.8 parts of nonionic polyurethane associative thickener ; Calculated by weight percentage, the composition of the anionic emulsified asphalt is: 61.5% of 70# asphalt, 4% of sodium lauryl sulfate, 0.1% of polyvinyl alcohol, 0.02% of emulsified silicone oil, and the rest is water.

[0037] The preparation method of this thixotropic water-based modified asphalt waterproof coating comprises the following steps:

[0038] (1) Put the measured water, anionic emulsifier, stabilizer, and defoamer into the emulsifier metering tank, adjust the pH value to 9 after heating to 90°C, and cool down to 80°C after stirring to obtain an emulsion for use;

[0039] (2) Heat 70# asphalt to 160°C and pump it into the asphalt metering tank, cool down to 130°C to obtain ...

Embodiment 2

[0046] The thixotropic water-based modified asphalt waterproof coating consists of the following components by weight: 32 parts of anionic emulsified asphalt, 6 parts of neoprene latex, 31 parts of water, 32 parts of quartz sand, and 0.7 parts of nonionic polyurethane associative thickener ; Calculated by weight percentage, the composition of the anionic emulsified asphalt is: 62% of 70# asphalt, 5% of sodium dodecylbenzenesulfonate, 0.1% of polyvinyl alcohol, 0.02% of emulsified silicone oil, and the rest is water.

[0047] The preparation method of this thixotropic water-based modified asphalt waterproof coating comprises the following steps:

[0048] (1) Put the measured water, anionic emulsifier, stabilizer, and defoamer into the emulsifier metering tank, adjust the pH value to 8 after heating to 90°C, and cool down to 80°C after stirring to obtain an emulsion for later use;

[0049] (2) Heat 70# asphalt to 160°C and pump it into the asphalt metering tank, cool down to 120...

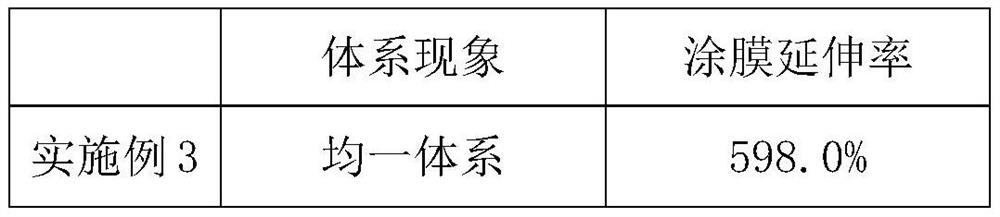

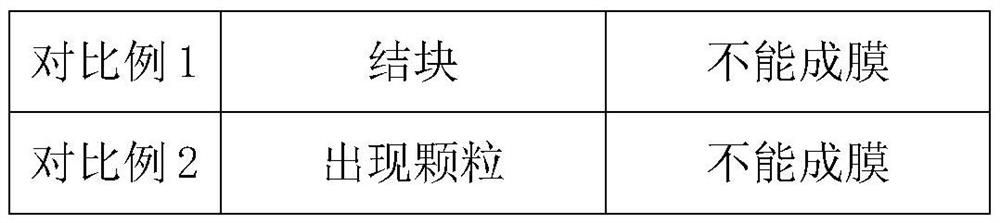

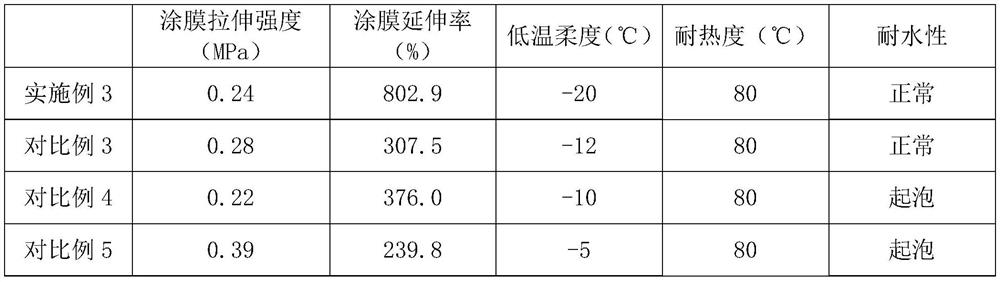

Embodiment 3

[0056] The thixotropic water-based modified asphalt waterproof coating consists of the following components by weight: 30 parts of anionic emulsified asphalt, 8 parts of neoprene latex, 30 parts of water, 33 parts of quartz sand, and 0.9 parts of nonionic polyurethane associative thickener ; Calculated by weight percentage, the composition of the anionic emulsified asphalt is: 61% of 70# asphalt, 4.5% of sodium lauryl sulfate, 0.1% of sodium carboxymethyl cellulose, 0.02% of emulsified silicone oil, and the rest is water.

[0057] The preparation method of this thixotropic water-based modified asphalt waterproof coating comprises the following steps:

[0058] (1) Put the measured water, anionic emulsifier, stabilizer, and defoamer into the emulsifier metering tank, adjust the pH value to 8.5 after heating to 90°C, stir evenly and cool down to 80°C to obtain the emulsion for later use;

[0059] (2) Heat 70# asphalt to 160°C and pump it into the asphalt metering tank, cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com