Method for promoting micro algae frond to rapidly accumulate grease

A microalgae algae, rapid technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms and other directions, can solve problems such as unfavorable large-scale application production, low oil conversion rate, complex technical process, etc. The effect of large-scale application production, improving conversion rate and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

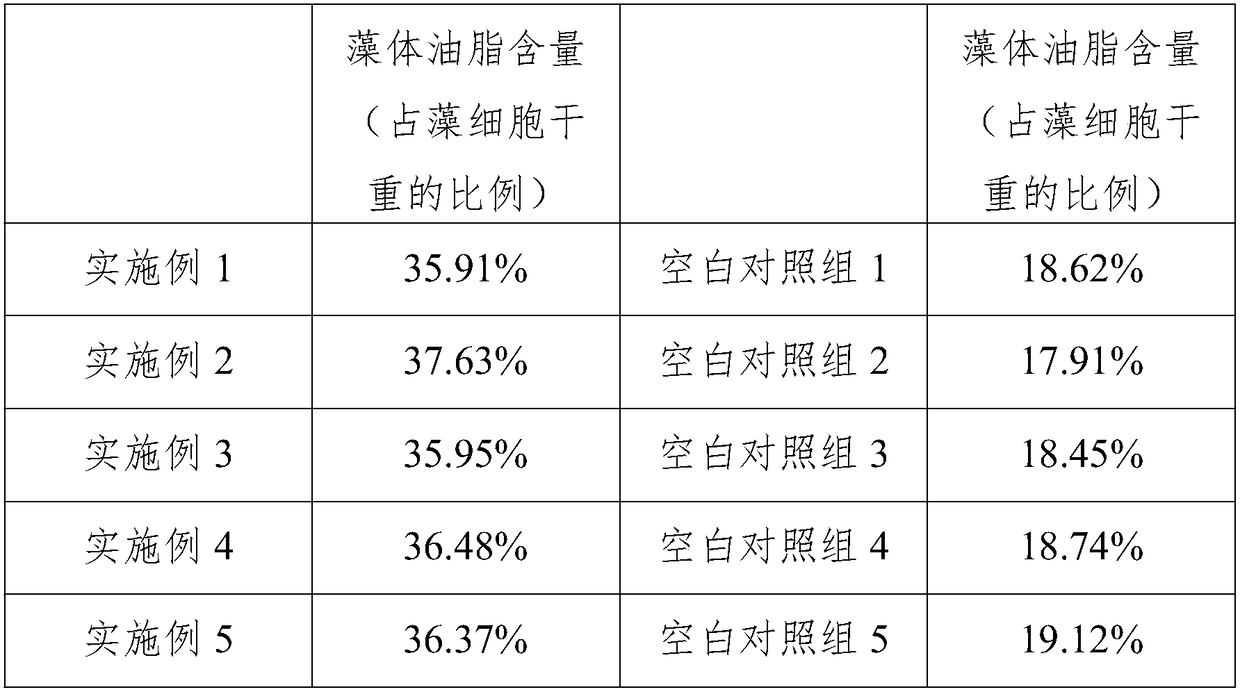

Examples

Embodiment 1

[0021] A method for promoting rapid accumulation of oil in microalgae, comprising the following steps:

[0022] (1) Preparation of algae liquid: under the conditions of temperature 23°C, light intensity 1850 lx, and light-dark ratio 12h / 12h, culture the microalgae to the logarithmic growth phase to obtain the algae liquid. The microalgae uses No. 9 freshwater pellets Algae;

[0023] (2) Hormone induction: brassinosterol is added to the 200ml algae liquid in step (1), until the final concentration of brassinosterol is 20.2mg / l;

[0024] (3) Obtain algae with high oil content: put the algae fluid induced by the hormone in step (2) in BG11 medium, cultivate it for 17 days under the conditions of temperature 24°C, light intensity 3900lx, and 24h continuous light, centrifuge and collect it. To obtain algae with high oil content, the centrifugation speed is 6000r / min, and the centrifugation time is 8min.

Embodiment 2

[0026] A method for promoting rapid accumulation of oil in microalgae, comprising the following steps:

[0027] (1) Preparation of algae liquid: culture the microalgae to the logarithmic growth phase under the conditions of temperature 24°C, light intensity 1900 lx, and light-dark ratio 12h / 12h, and obtain the algae liquid. The microalgae uses No. 31 freshwater pellets Algae;

[0028] (2) Hormone induction: brassinosterol is added to the 220ml algae liquid in step (1), until the final concentration of brassinosterol is 20.4mg / l;

[0029] (3) Obtain algae with high oil content: place the algae fluid induced by the hormone in step (2) in BG11 medium, culture it for 18 days under the conditions of temperature 25°C, light intensity 3950lx, and 24h continuous light, then centrifuge and collect it. To obtain algae with high oil content, the centrifugation speed is 6300r / min, and the centrifugation time is 7min.

Embodiment 3

[0031] A method for promoting rapid accumulation of oil in microalgae, comprising the following steps:

[0032] (1) Preparation of algae liquid: under the conditions of temperature 25°C, light intensity 1950lx, and light-to-dark ratio 12h / 12h, culture the microalgae to the logarithmic growth phase to obtain the algae liquid. The microalgae uses No. 9 freshwater pellets Algae;

[0033] (2) Hormone induction: brassinosterol is added to the 250ml algae liquid in step (1), until the final concentration of brassinosterol is 20.8mg / l;

[0034] (3) Obtain algae with high oil content: place the algae fluid induced by the hormone in step (2) in BG11 medium, culture it for 19 days at a temperature of 224°C, a light intensity of 4000 lx, and 24 hours of continuous light, then centrifuge and collect it. To obtain algae with high oil content, the centrifugation speed is 7000r / min, and the centrifugation time is 6min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com