Polyamine ethanolamine alkaline foaming agent and use for preparing polyurethane solar foam material

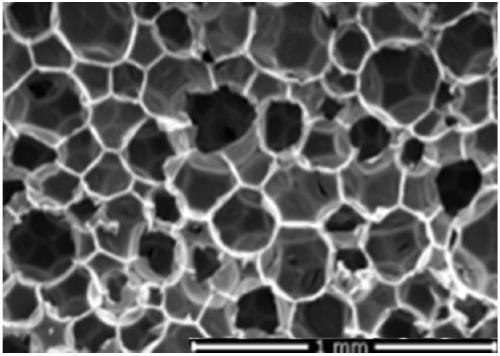

A foaming agent and ethanolamine salt technology, which is applied in the field of polyamine ethanolamine alkaline foaming agent and used for preparing polyurethane solar foam materials, can solve the problem of uneven cell size, uneven distribution of cells, and influence on foaming. Strength properties and thermal insulation properties of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] Add 3kg of 40% ethylenediamine aqueous solution (molecular weight 60) into a transparent quartz glass reactor, stir to dissolve, seal the reactor, then, under constant stirring, control the temperature between 40-65°C, and pass carbon dioxide into In the reactor, control the pressure not to be higher than 0.3MPa, control the temperature and react for 10 hours, release the pressure and release the product after the temperature is lowered to below 40°C. Compound 1 was obtained. pH≥7.5, decomposition temperature is 42°C-70°C.

preparation example 2

[0071] The 50% diethylenetriamine aqueous solution (molecular weight 103) of 3kg is joined in the transparent quartz glass reactor, stirs to dissolve, seals the reactor, then under constant stirring, controls the temperature between 40-65 ℃, will Pass carbon dioxide into the reactor, control the pressure not to be higher than 0.3 MPa, and control the temperature for 10 hours to react. After cooling down to below 40°C, release the pressure and release the product. Compound 2 was obtained. pH≥7.5, decomposition temperature is 42°C-70°C.

preparation example 3

[0073] Add 3kg of triethylenetetramine (molecular weight 146) and 1.8kg of water into a transparent quartz glass reactor, stir to dissolve, seal the reactor, and then control the temperature between 40-65°C under constant stirring, Pass carbon dioxide into the reactor, control the pressure not higher than 0.3MPa, control the temperature and react for 10 hours, release the pressure and release the product after cooling down to below 40°C. Compound 3 was obtained. pH≥7.5, decomposition temperature is 42°C-70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com